302 Stainless Steel Spring Wire: Durable, Versatile, and Cost-Effective Solutions

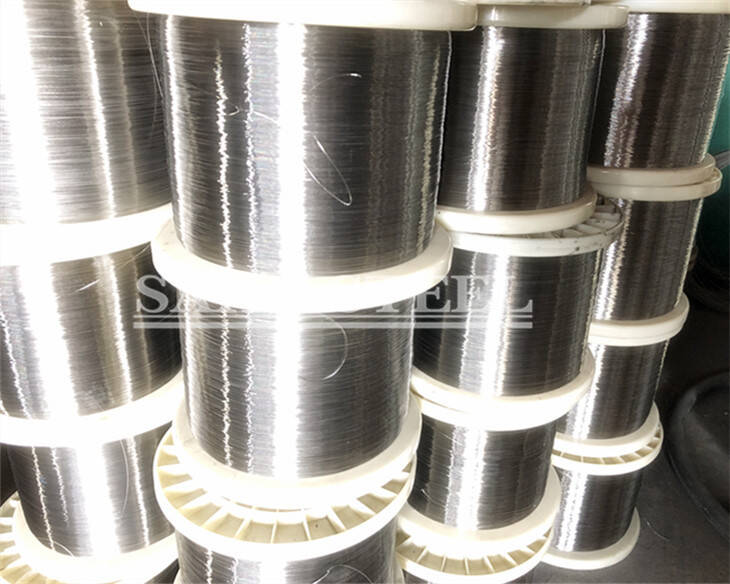

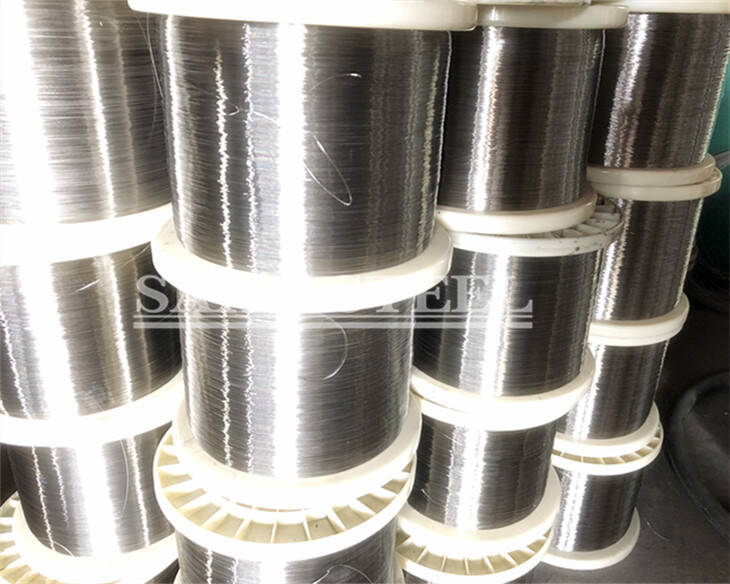

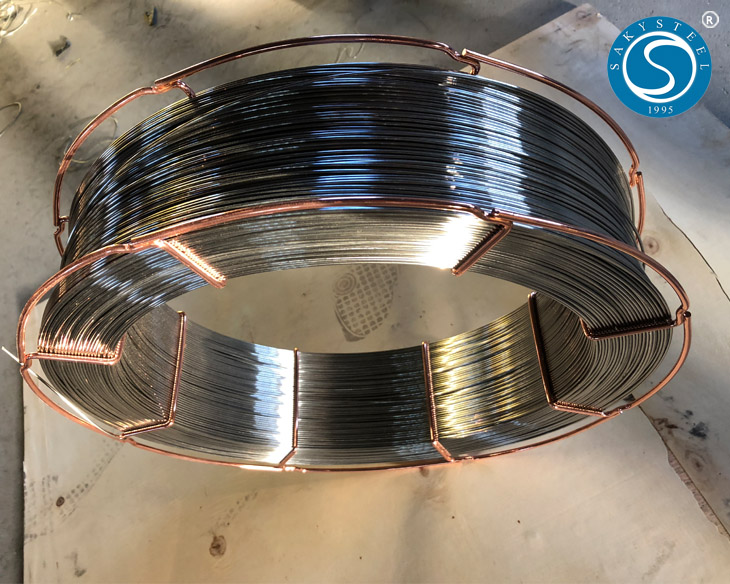

When searching for high-quality wire that can withstand high-stress applications, 302 stainless steel spring wire is your go-to choice. With excellent corrosion resistance and great tensile strength, this material perfectly suits various projects—from automotive parts to industrial springs. I often recommend this wire because it maintains shape and resists deforming even in demanding conditions. Whether you’re crafting compression springs, extension springs, or any other custom wire forms, 302 stainless steel offers the durability you need. Plus, it’s relatively easy to work with, making it ideal for both experienced fabricators and newcomers. If you're sourcing raw materials or planning a larger production, I'm here to help streamline your process. Let's make sure you get the exact specifications and quantities you require to keep your projects on track. Feel free to reach out with your needs!

302 Stainless Steel Spring Wire Factory Where Innovation Meets 2025

In the fast-evolving world of industrial materials, the demand for high-quality stainless steel spring wire is at an all-time high. As we move toward 2025, innovations in production techniques and material science are shaping the landscape of manufacturing, particularly in the field of 302 stainless steel spring wire. Known for its excellent corrosion resistance and impressive strength, 302 stainless steel is becoming the material of choice for various applications, ranging from automotive parts to electronic components. Understanding the global market's needs, manufacturers are now prioritizing the integration of cutting-edge technology in their processes. This includes advancements in precision wire forming, enhanced quality control measures, and sustainable production practices. Buyers looking for reliable supply sources will find that factories committed to these innovations not only offer superior products but also ensure consistent supply chains, timely deliveries, and competitive pricing. Collaborating with a forward-thinking manufacturer that emphasizes innovation will provide procurement professionals with the resources they require. These partnerships foster a shared vision for quality and efficiency, ultimately leading to improved performance in end-use applications. As the industry moves closer to 2025, leveraging the advantages of advanced manufacturing in stainless steel spring wire production will be essential for businesses aiming to stay ahead in the competitive landscape.

302 Stainless Steel Spring Wire Factory Where Innovation Meets 2025

| Dimension (mm) | Tensile Strength (MPa) | Elongation (%) | Application | Certification |

|---|---|---|---|---|

| 0.5 | 800 | 15 | Automotive Parts | ISO 9001 |

| 1.0 | 850 | 12 | Spring Manufacturing | ASTM A313 |

| 1.5 | 900 | 10 | Industrial Equipment | RoHS |

| 2.0 | 950 | 8 | Home Appliances | CE |

| 2.5 | 1000 | 7 | Construction | ANSI |

Related Products