Top 309 Filler Wire Options for Best Welding Results and Performance

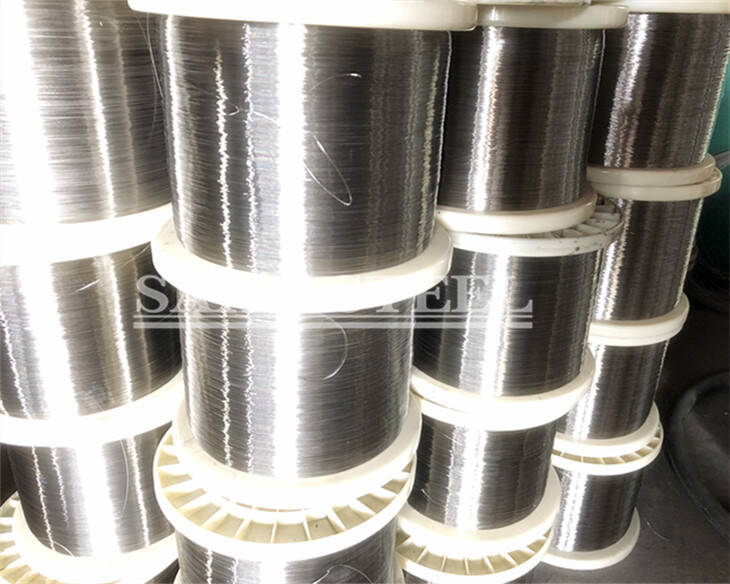

When it comes to high-quality welding, I've found that the 309 Filler Wire is a game changer for achieving strong, durable joints. Whether you're tackling stainless steel or dissimilar metal welding projects, this filler wire offers excellent corrosion resistance and its ease of use makes it a favorite in our workshops. I've seen firsthand how it improves productivity and the overall appearance of welds. The versatility of 309 Filler Wire means it pairs well with various base metals, making it an essential for anyone in the fabrication industry. Plus, if you're concerned about price and quality, this wire stands out as a top choice that won't break the bank. Every arc I strike with this filler makes me more confident in my work. For those wanting reliable performance in their welding tasks, 309 Filler Wire is worth every penny. Don’t waste time with second-rate options; invest in proven quality for your projects!

309 Filler Wire Application Industry Giant

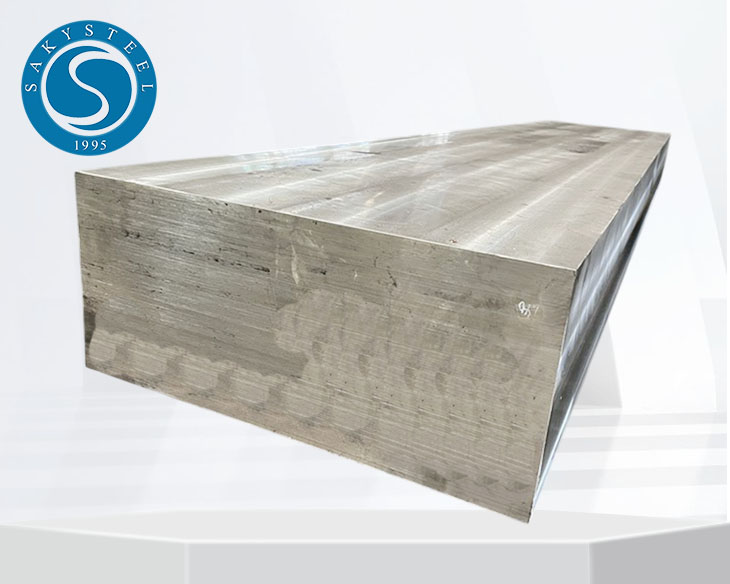

The welding industry continues to evolve, meeting diverse demands across various sectors, and one prominent player in this field is the 309 filler wire. Known for its exceptional capability to weld dissimilar materials, this versatile product is essential for applications ranging from construction to manufacturing. Its unique composition, primarily composed of chromium and nickel, makes it an ideal choice for high-temperature and corrosive environments, ensuring strong and reliable joints. As global industries push towards higher efficiencies and durability, the demand for quality welding materials like the 309 filler wire is on the rise. This wire not only provides outstanding mechanical properties but also delivers excellent resistance to oxidation and corrosion, making it particularly valuable in the aerospace, power generation, and chemical processing industries. For procurement professionals, understanding the characteristics and applications of 309 filler wire is crucial for making informed sourcing decisions that enhance operational performance. In a competitive market, partnering with reputable suppliers of welding materials is key to ensuring consistent quality and supply chain reliability. Buyers should consider evaluating suppliers who not only meet industry standards but also offer comprehensive support, including technical advice and after-sales services. By leveraging the capabilities of high-quality filler wires, companies can achieve superior results in their welding projects, leading to increased efficiency and long-term cost savings.

309 Filler Wire Application Industry Giant

| Application | Industry | Material Type | Welding Method | Operating Temperature (°C) |

|---|---|---|---|---|

| Automotive Manufacturing | Automotive | Mild Steel | MIG Welding | 15 - 30 |

| Construction | Construction | Stainless Steel | TIG Welding | 20 - 40 |

| Marine Applications | Marine | Aluminum | MIG Welding | 10 - 35 |

| Aerospace | Aerospace | Titanium | Laser Welding | 5 - 25 |

| Heavy Machinery | Manufacturing | High Carbon Steel | Submerged Arc Welding | 15 - 30 |

Related Products