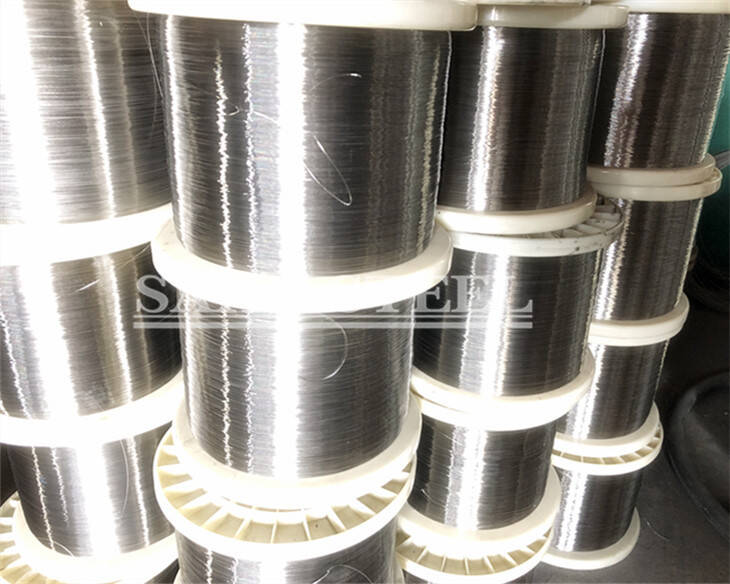

High-Quality 310 Stainless Steel Wire for Reliable Applications

When I think about reliable materials for my projects, 310 Stainless Steel Wire always comes to mind. Its exceptional heat resistance and durability make it perfect for high-temperature applications, and I often recommend it to fellow professionals in the industry. I’ve found that this wire is not just versatile; it also offers excellent corrosion resistance, making it ideal for a variety of environments. Many of my clients appreciate its high tensile strength, which ensures long-lasting performance. If you're in need of a dependable solution, investing in 310 Stainless Steel Wire can enhance your product quality significantly. Plus, with the right supplier, you’ll find competitive pricing that supports your budget without compromising on quality. Whether you’re fabricating or manufacturing, this wire fits the bill for your needs and helps me achieve success in my projects. Let's connect and make sure you get the right material for your business.

310 Stainless Steel Wire Leads the Global Market Exceeds Industry Benchmarks

In the competitive landscape of stainless steel production, 310 stainless steel wire has emerged as a frontrunner, setting new global standards and exceeding industry benchmarks. Known for its exceptional resistance to oxidation and a wide range of temperatures, this alloy is ideal for demanding applications in various sectors including aerospace, automotive, and petrochemical industries. With a seamless combination of strength and flexibility, 310 stainless steel wire is engineered to deliver superior performance even in the harshest environments. For global purchasers seeking high-quality materials, investing in 310 stainless steel wire opens the door to enhanced durability and operational efficiency. The unique properties of this alloy not only lower maintenance costs but also extend the lifespan of equipment, thereby providing a compelling value proposition. As industries move towards more sustainable practices, the reliability and versatility of 310 stainless steel wire make it an indispensable choice for manufacturing and construction projects worldwide. As the market continues to evolve, staying updated with the latest advancements in stainless steel technology is crucial. Suppliers who prioritize quality and innovation in their offerings are well-positioned to meet the growing demands of modern industries. Embracing 310 stainless steel wire can empower businesses to tackle challenges head-on while ensuring compliance with rigorous industry standards. Partnering with a trusted source of this exceptional material can streamline procurement processes and bolster overall project success.

310 Stainless Steel Wire Leads the Global Market Exceeds Industry Benchmarks

| Region | Market Share (%) | Production Volume (tons) | Growth Rate (%) | Key Applications |

|---|---|---|---|---|

| North America | 35 | 15,000 | 5 | Aerospace, Automotive |

| Europe | 30 | 12,000 | 4.5 | Medical Devices, Construction |

| Asia-Pacific | 25 | 10,000 | 6 | Energy, Industrial |

| Latin America | 5 | 2,000 | 3 | Manufacturing, Robotics |

| Middle East & Africa | 5 | 1,500 | 4 | Construction, Oil & Gas |

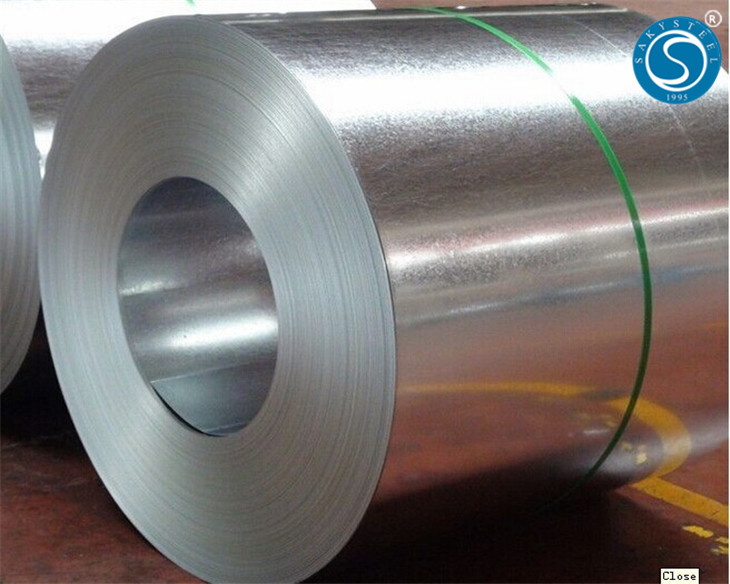

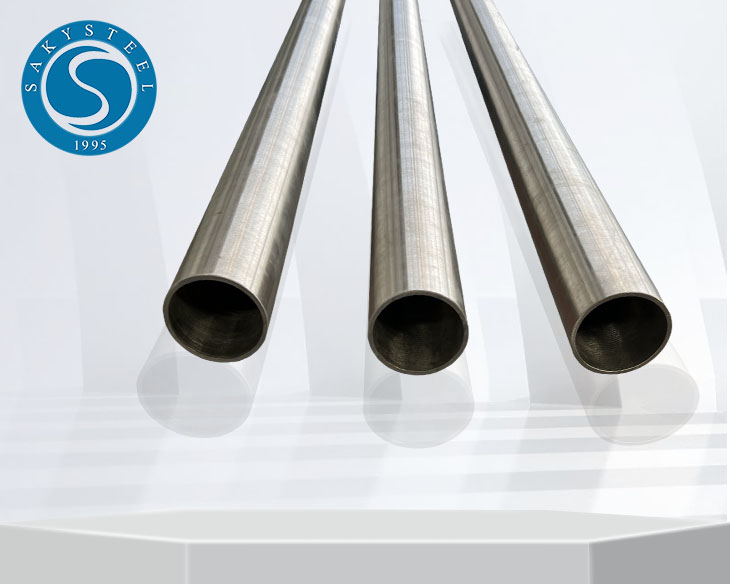

Related Products