Common heat-resistant stainless steel is generally divided into three kinds, 309S, 310S and 253MA, heat-resistant steel is often used in the manufacture of boilers, steam turbines, industrial furnaces and aviation, petrochemical and other industrial sectors in the high temperature working parts.

1.309s: (OCr23Ni13) stainless steel plate

Characteristics: It can withstand repeated heating below 980 ℃, with high high temperature strength, oxidation resistance and carburizing resistance.

Application: furnace material, can be used to manufacture hot steel parts,Its high chromium and nickel content ensures good corrosion resistance and oxidation resistance.

Compared with austenitic 304 alloy, it is slightly stronger at room temperature. In real life, it can be repeatedly heated at 980 ° C to maintain normal work.310s: (0Cr25Ni20) stainless steel plate.

2.310s: (OCr25Ni20) stainless steel plate

Characteristics: High chromium-nickel austenitic stainless steel with good high temperature mechanical properties and good corrosion resistance in oxidizing media. Suitable for the production of various furnace components, the highest temperature 1200 ℃, continuous use temperature 1150 ℃.

Application: furnace material, automobile purification device material.

310S stainless steel is a highly corrosion-resistant austenitic stainless steel alloy that is used in various high-temperature and corrosive environments. It is an excellent choice for applications in the petrochemical, chemical, and heat-treating industries, as well as for furnace components and other high-temperature applications. A 310S stainless steel plate is a flat, thin sheet made from this specific alloy.

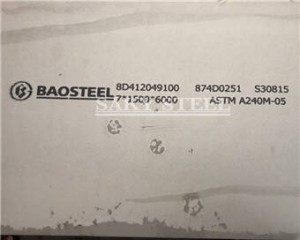

3.253MA (S30815) stainless steel plate

Characteristics: 253MA is a heat-resistant Austenitic stainless steel designed for applications requiring high creep strength and good corrosion resistance. Its operating temperature range is 850-1100 ℃.

253MA is a specific type of stainless steel alloy that is designed for high-temperature applications. It offers excellent resistance to oxidation, sulfidation, and carburization at elevated temperatures. This makes it suitable for use in various industries, including those involving heat and corrosion, such as the petrochemical, power generation, and industrial furnace sectors.253MA sheets are thin, flat pieces of material made from this alloy. They are used in various applications where the combination of high-temperature resistance and corrosion resistance is essential. The sheets can be cut and formed into different shapes to meet the specific requirements of a project.

253MA Sheets, Plates Chemical Composition

| Grade | C | Cr | Mn | Si | P | S | N | Ce | Fe | Ni |

| 253MA | 0.05 – 0.10 | 20.0-22.0 | 0.80 max | 1.40-2.00 | 0.040 max | 0.030 max | 0.14-0.20 | 0.03-0.08 | Balance | 10.0-12.0 |

253MA Plate Mechanical properties

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation(in 2 in.) |

| Psi:87,000 | Psi 45000 | 40 % |

253MA Plate Corrosion resistance and main use environment:

1.Corrosion Resistance: 253MA boasts excellent oxidation resistance, high-temperature corrosion resistance, and remarkable high-temperature mechanical strength. It is particularly effective within the temperature range of 850 to 1100°C.

2.Temperature Range: For optimal performance, 253MA is best suited for use within the temperature range of 850 to 1100°C. At temperatures between 600 and 850°C, structural changes occur, leading to reduced impact toughness at room temperature.

3.Mechanical Strength: This alloy surpasses ordinary stainless steels, such as 304 and 310S, in terms of short-term tensile strength at various temperatures by over 20%.

4.Chemical Composition: 253MA features a balanced chemical composition that grants it exceptional performance in the temperature range of 850-1100°C. It exhibits extremely high oxidation resistance, withstanding temperatures up to 1150°C. It also offers superior creep resistance and creep fracture strength.

5.Corrosion Resistance: In addition to its high-temperature capabilities, 253MA displays excellent resistance to high-temperature corrosion and brush corrosion in most gaseous environments.

6.Strength: It possesses high yield strength and tensile strength at elevated temperatures.

7.Formability and Weldability: 253MA is known for its good formability, weldability, and machinability.

Post time: Oct-09-2023