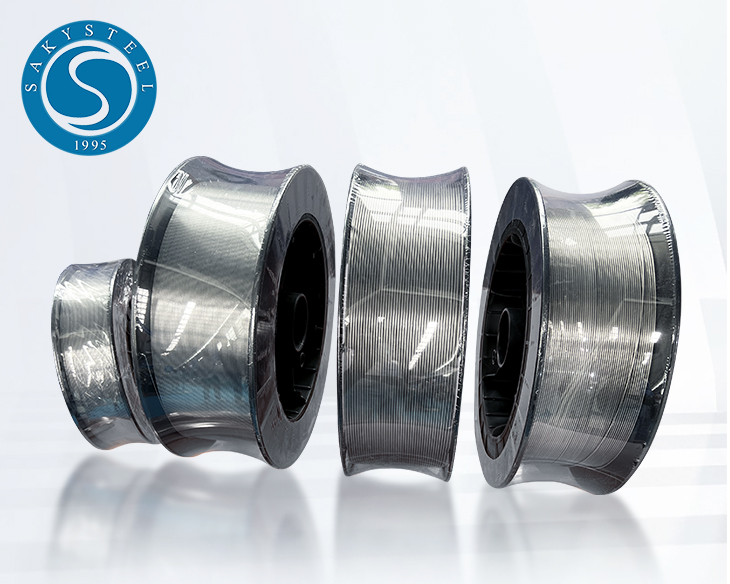

Er2209 Welding Wire for Superior Performance and Durability in Projects

Are you in need of high-quality welding materials? Our ER2209 Welding Wire is the perfect solution for your welding projects that require strength and durability. With excellent corrosion resistance and outstanding weldability, this wire is specifically designed for welding duplex stainless steel. I’ve seen firsthand how it enhances the performance of various constructions and industrial applications. Whether you’re tackling large-scale projects or smaller components, you’ll appreciate its consistent feed and minimal spatter, which translates to cleaner welds. I find it especially useful for fabricating equipment exposed to harsh environments. Plus, our competitive pricing and reliable supply chain ensure that you have what you need when you need it. If you're considering a reliable welding wire that meets industry standards, the ER2209 Welding Wire could be an essential part of your toolkit. Let’s boost your productivity with superior welding solutions that you can trust!

Er2209 Welding Wire Leads the Global Market More Than a Supplier - A Partner

In the ever-evolving landscape of the welding industry, sourcing the right materials can be a daunting task for procurement professionals. The introduction of Er2209 welding wire not only sets a new benchmark in quality and performance but also emphasizes the importance of partnerships over mere transactional relationships. As a forward-thinking supplier, we understand the complexities faced by global buyers and aim to be more than just a vendor; we strive to be your strategic partner in success. Er2209 welding wire is engineered for excellence, offering superior corrosion resistance and strength, making it ideal for projects demanding high durability. This innovative product not only elevates the integrity of your welding tasks but also ensures seamless operations, reducing downtime and enhancing productivity. Our commitment to quality extends beyond the product itself; we provide tailored solutions and expert guidance, ensuring that your specific requirements are met every step of the way. Choosing Er2209 isn't just about procurement; it's about building a reliable partnership that fosters growth and innovation. By collaborating closely, we empower our clients to navigate challenges effectively, optimize their processes, and achieve their goals with confidence. Join us in transforming the welding industry by prioritizing quality, performance, and partnership over mere supply. Together, we can lead the market into a new era of success.

Er2209 Welding Wire Leads the Global Market More Than a Supplier - A Partner

| Category | Specification | Application | Market Share (%) | Growth Rate (%) |

|---|---|---|---|---|

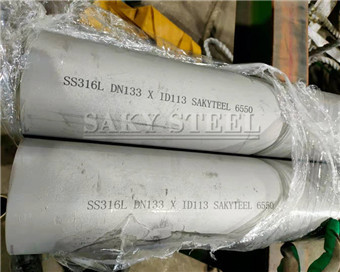

| Welding Wire Type | Er2209 | Stainless Steel Welding | 30 | 12 |

| Welding Process | GTAW | Pipe and Tube | 25 | 10 |

| Region | Asia-Pacific | Oil & Gas | 40 | 15 |

| Quality Standard | ISO 9001 | Construction | 20 | 8 |

| Customer Segment | Industrial | Manufacturing | 35 | 14 |

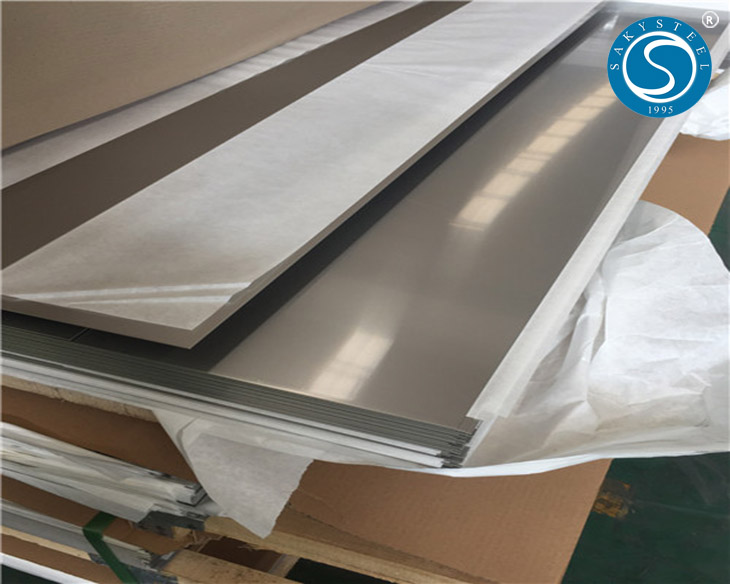

Related Products