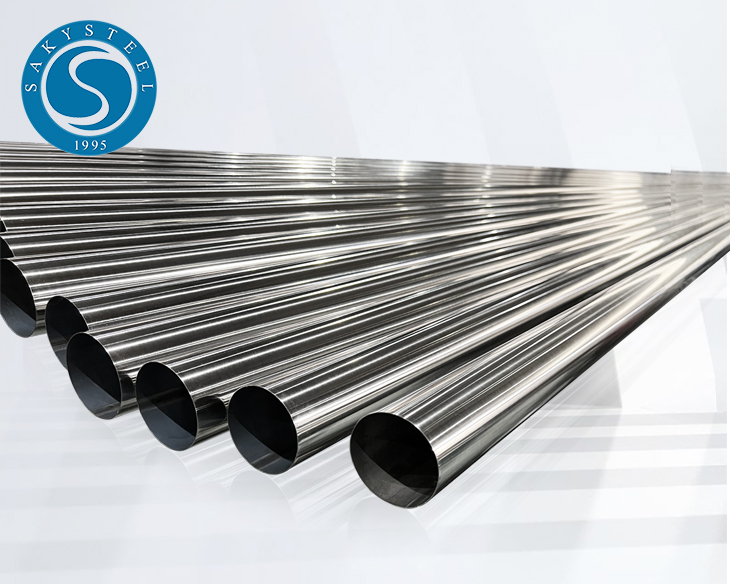

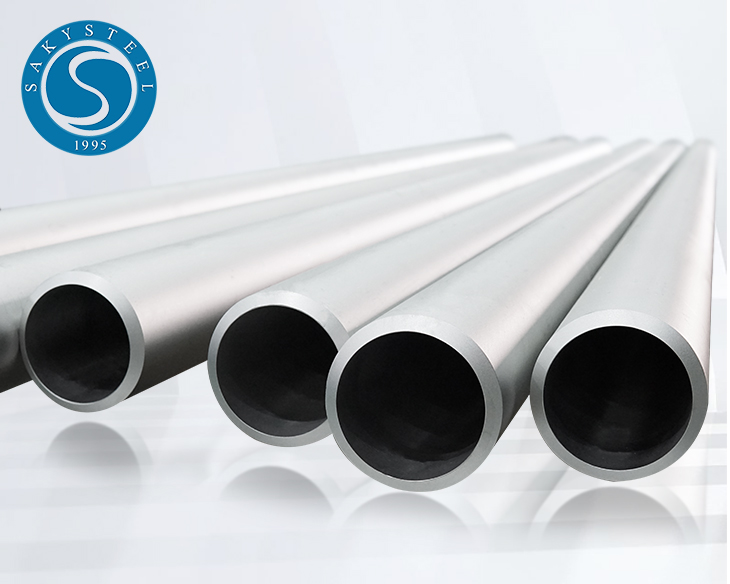

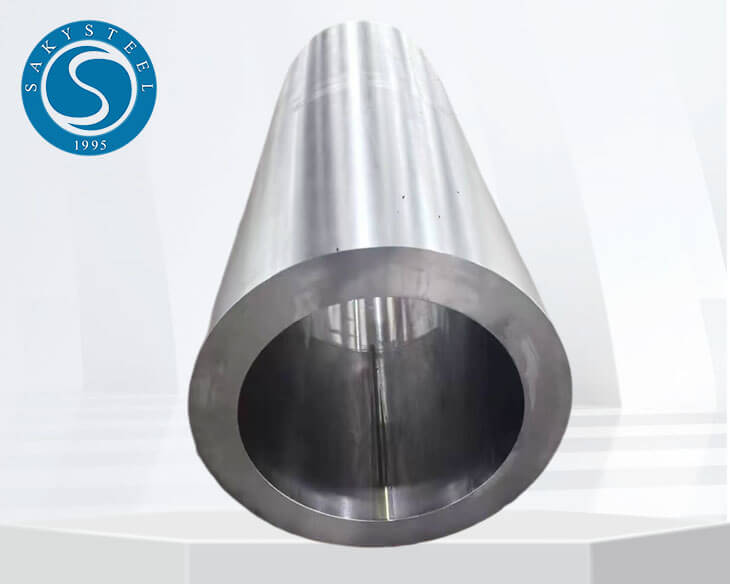

Premium Stainless Pipe Flanges for Reliable Industrial Applications

When you need reliable and durable solutions for your piping systems, stainless pipe flanges are the answer. With a variety of options available, I understand how crucial it is to find the right fit for your specific applications. Whether you’re working on high-pressure projects or projects where corrosion resistance is key, stainless pipe flanges offer exceptional performance and longevity. Our flanges are not just products; they are designed to meet the demands of today’s industries. I’ve seen firsthand how they improve efficiency and reduce downtime, allowing you to focus on what really matters—your business. Plus, with competitive pricing and customizable sizes, you can find just what you need without breaking the bank. Let’s talk about how our stainless pipe flanges can elevate your operations and ensure your piping systems are up to standard!

Stainless Pipe Flanges Service Custom Solutions,

When it comes to sourcing high-quality stainless pipe flanges, global procurement professionals demand customized solutions that meet specific project requirements. Understanding the unique needs of each industry, manufacturers now offer tailored flange services that encompass everything from material selection to precise dimensions and surface finishes. This customization ensures that the flanges not only fit seamlessly into existing systems but also adhere to all relevant industry standards for safety and reliability. In addition to customization, the importance of durability and performance in demanding environments cannot be overstated. Stainless steel flanges are renowned for their corrosion resistance and strength, making them ideal for applications in chemical processing, petrochemical, and marine industries. By choosing suppliers with a proven track record in quality assurance and advanced manufacturing techniques, buyers can ensure a consistent product that enhances operational efficiency. Furthermore, efficient logistics and timely delivery play a crucial role in maintaining project timelines. Collaborating with experienced suppliers enables procurement teams to benefit from streamlined processes that facilitate quick turnaround times while minimizing supply chain disruptions. Embracing these customized flange solutions not only meets immediate project needs but also fosters long-term partnerships built on trust and reliability in meeting market demands.

Stainless Pipe Flanges Service Custom Solutions

| Flange Type | Material | Diameter (inches) | Thickness (mm) | Pressure Rating (ANSI) | Custom Options |

|---|---|---|---|---|---|

| Slip-On Flange | 304 Stainless Steel | 6 | 10 | 150 | Custom drilling options |

| Weld Neck Flange | 316L Stainless Steel | 8 | 12 | 300 | Custom sizes and finish |

| Blind Flange | Duplex Stainless Steel | 10 | 15 | 600 | Special coatings available |

| Socket Weld Flange | Carbon Steel | 4 | 8 | 150 | Machining services offered |

Related Products