Top Stainless Steel Filler Wire for Optimal Welding Performance & Durability

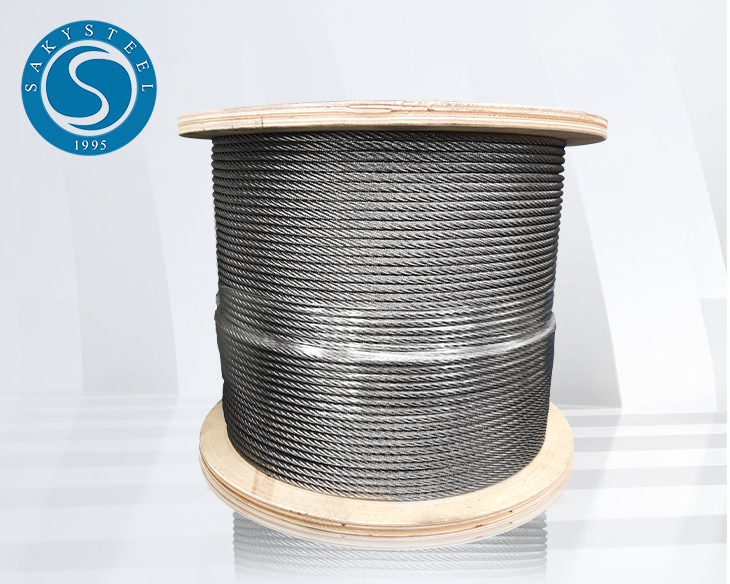

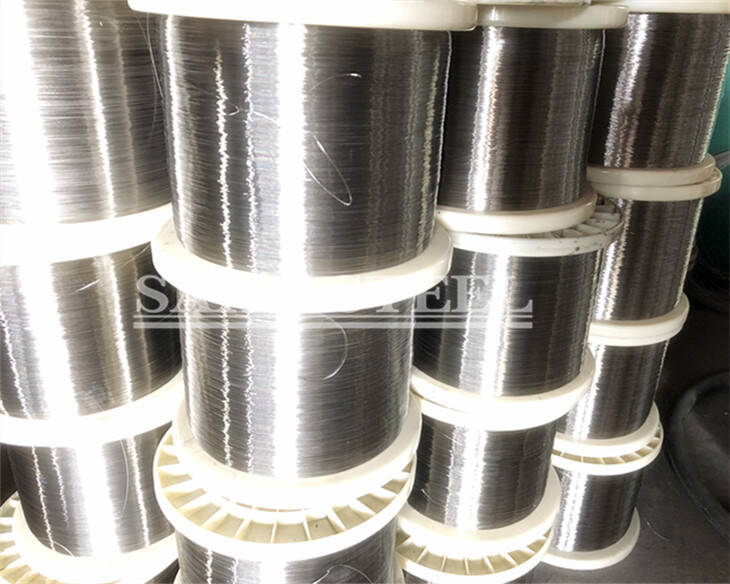

As a professional in the welding industry, I've seen the huge difference that high-quality stainless steel filler wire can make in achieving strong and durable welds. Our stainless steel filler wire is perfect for various applications, ensuring excellent corrosion resistance and weld integrity. Whether you’re working on piping, tanks, or structural components, this filler wire meets the demands of any project. With features like enhanced feedability and minimal spatter, it saves valuable time and effort during welding. I always recommend checking out testimonials from other buyers who experienced improved welding performance. If you’re aiming for top-notch results and looking for reliable options, you’ll appreciate the quality we offer. Plus, with competitive pricing and fast delivery options, you won’t be disappointed in your choice. Let’s elevate your welding projects with the best stainless steel filler wire on the market!

Stainless Steel Filler Wire Application Sets the Industry Standard

The use of stainless steel filler wire is essential in various industries, particularly in welding and fabrication processes. As demand for durable and corrosion-resistant materials grows, the application of stainless steel filler wires is setting new industry standards. These wires are crafted to ensure excellent mechanical properties, enabling them to withstand extreme conditions while providing superior weld quality. From automotive manufacturing to the construction of offshore structures, the versatility of stainless steel filler wire makes it a preferred choice for professionals seeking reliability and performance in their projects. In addition to their effectiveness in joining similar and dissimilar metals, these filler wires exhibit exceptional resistance to oxidation and chemical exposure. This resilience is crucial for industries that require high-performance materials in demanding environments. Moreover, advancements in technology and manufacturing processes have led to the development of filler wires with enhanced welding characteristics, ensuring ease of use and consistency across various applications. For global procurers, sourcing high-quality stainless steel filler wire becomes essential not only for operational efficiency but also for compliance with stringent industry standards and regulations. As industries evolve, the need for innovative solutions that enhance productivity and reduce operational costs has never been more paramount. Emphasizing the importance of quality filler materials, companies that prioritize stainless steel filler wire applications position themselves at the forefront of the market. By investing in these advanced materials, businesses can ensure superior performance, trustworthiness, and sustainability, paving the way for future growth and competitiveness in the global landscape.

Stainless Steel Filler Wire Application Sets the Industry Standard

| Application Area | Wire Diameter (mm) | Common Alloy Types | Typical Uses |

|---|---|---|---|

| Automotive | 0.8 | AISI 304, AISI 316 | Exhaust systems, chassis |

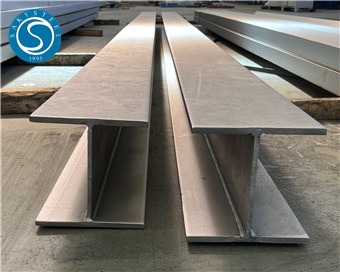

| Construction | 1.2 | AISI 308, AISI 316L | Structural steel, beams |

| Marine | 1.0 | AISI 316, AISI 2205 | Boat hulls, propellers |

| Food Industry | 0.6 | AISI 304L, AISI 316L | Food processing equipment |

| Pipelines | 1.0 | AISI 304, AISI 316 | Oil and gas transportation |

Related Products