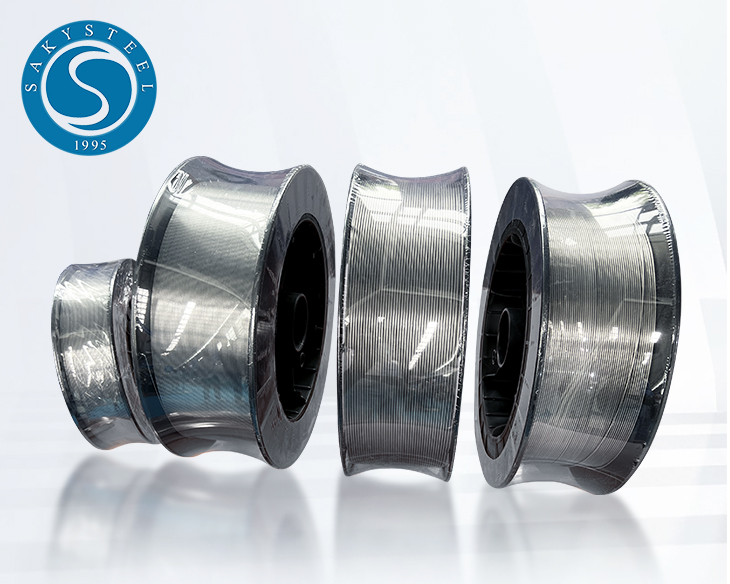

High-Quality Stainless Steel Tig Wire for Optimal Welding Performance

When I think about high-quality welding materials, Stainless Steel Tig Wire always comes to mind. It's perfect for achieving strong, durable welds in various applications, whether you're working on automotive, marine, or structural projects. I can't emphasize enough how its superb corrosion resistance and flawless finish makes a significant difference in the final product. One thing I appreciate is its user-friendly nature. Even if you're new to welding, you'll find that this wire feeds smoothly and produces clean welds. I often recommend it to those looking for reliability and performance at a competitive price. Choosing the right wire can transform your work, and with Stainless Steel Tig Wire, you'll be investing in a product that meets industry standards while catering to diverse buyer needs. Whether you’re a small shop or a large manufacturer, this wire can elevate your welding projects. Let’s enhance our welding results together!

Stainless Steel Tig Wire Industry Leaders Delivers Unmatched Quality

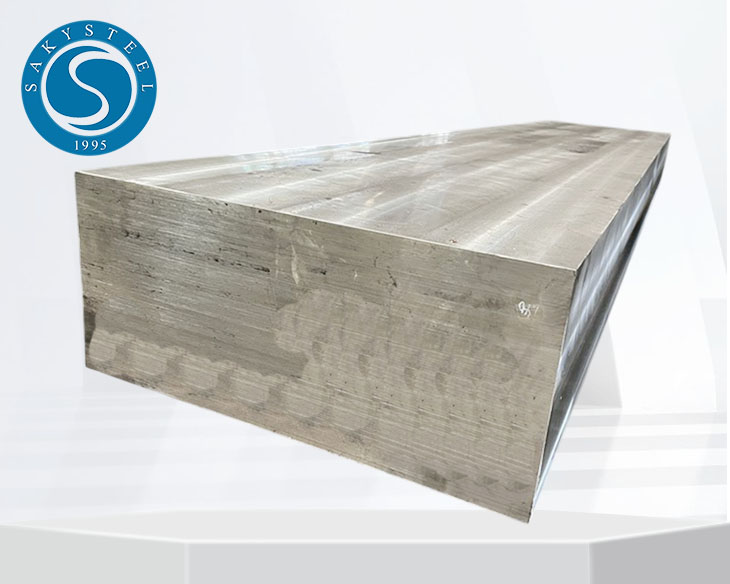

In an era where quality and precision in manufacturing are paramount, the stainless steel TIG wire industry stands out for its commitment to excellence. Leading manufacturers are dedicated to providing unmatched quality, ensuring that their products meet the most rigorous standards in various applications. This commitment is particularly crucial for businesses operating globally, where reliability and performance can significantly influence project outcomes and client satisfaction. The innovation in stainless steel TIG wire production has led to advancements in metallurgy and quality control processes. Companies at the forefront utilize state-of-the-art technologies to refine manufacturing techniques, resulting in wires that not only offer superior weldability but also exhibit exceptional strength and corrosion resistance. For procurement professionals, sourcing from these industry leaders means investing in products that enhance efficiency while reducing downtime and maintenance costs. Moreover, with an increasing demand for environmentally sustainable practices, top manufacturers are also focusing on eco-friendly production methods. By implementing sustainable sourcing and reducing waste, they not only contribute to a healthier planet but also align with the values of conscientious businesses. For global buyers, partnering with manufacturers who prioritize quality and sustainability ensures a competitive edge in today's market, paving the way for long-term success.

Stainless Steel Tig Wire Industry Leaders Delivers Unmatched Quality

| Manufacturer | Product Type | Diameter (mm) | Material Grade | Coating Type | Application |

|---|---|---|---|---|---|

| Manufacturer A | TIG Wire | 1.6 | 304 | None | Food Processing |

| Manufacturer B | TIG Wire | 2.4 | 316L | Argon | Marine Applications |

| Manufacturer C | TIG Wire | 1.0 | 321 | None | Chemical Processing |

| Manufacturer D | TIG Wire | 2.0 | 309 | None | Construction |

Related Products