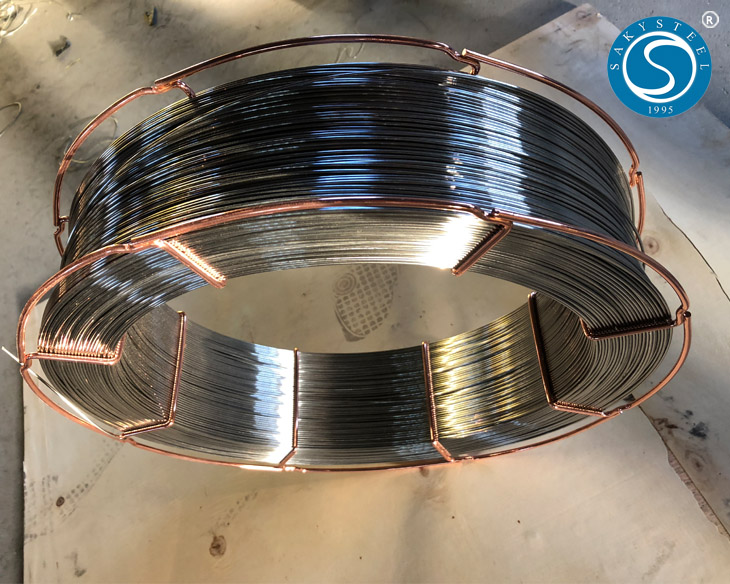

Premium Stainless Tig Welding Rods for Durable Welding Projects

As a seasoned welder, I understand the importance of using high-quality materials for stainless tig welding. Our stainless tig welding rod stands out with its superb strength and excellent corrosion resistance, ensuring a reliable and long-lasting weld. It's perfect for a variety of applications, from food processing to petrochemical industries, making it an ideal choice for your projects. When I first tried this welding rod, I was impressed by how easy it was to work with, producing clean, strong joints every time. Whether you’re in need of something for light repairs or heavy-duty fabrication, this rod delivers consistent results, helping you meet tight deadlines without compromising on quality. Plus, our competitive pricing and bulk purchasing options make it cost-effective for businesses looking to stock up. Trust me; investing in these stainless tig welding rods is a decision you won’t regret. Let's elevate your welding projects to the next level!

Stainless Tig Welding Rod Is The Best Dominates

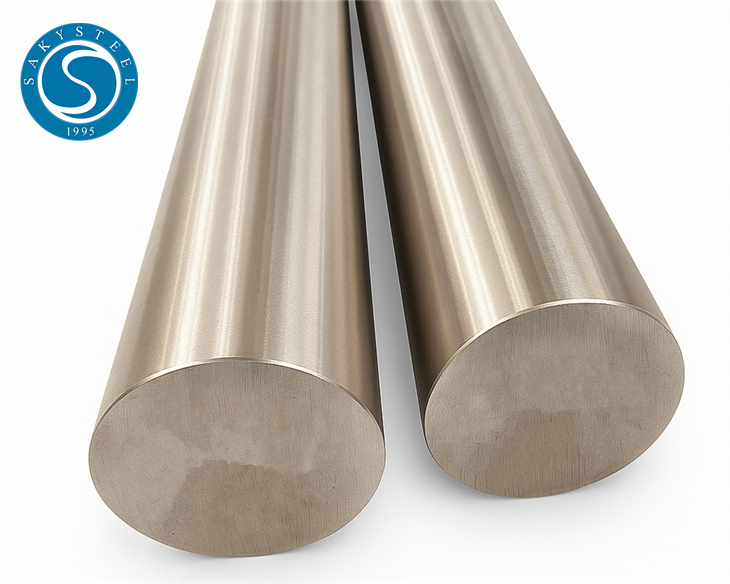

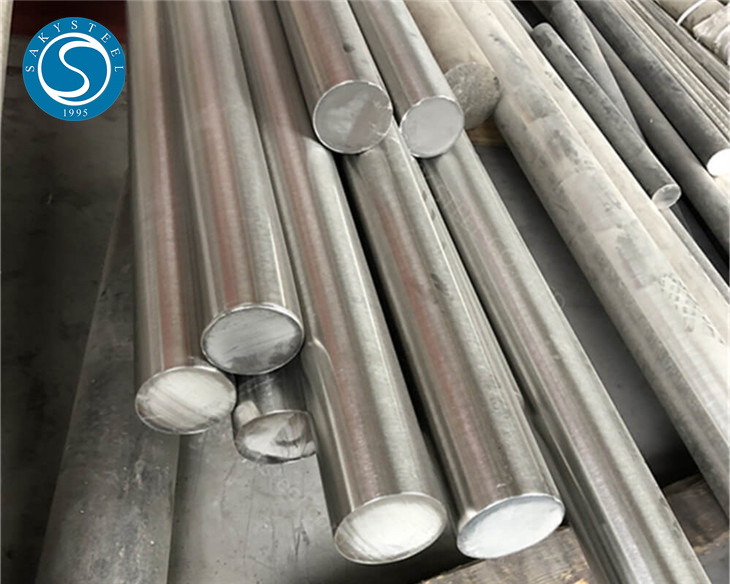

When it comes to precision and quality in stainless TIG welding, the choice of welding rod plays a pivotal role in ensuring the integrity of the welded joints. Stainless TIG welding rods are celebrated for their superior performance and reliability, and for many reason, they have become a preferred choice among global purchasers. Their ability to produce clean, focused welds without the need for added filler material makes them a go-to solution for industries requiring high strength and corrosion resistance. The attributes of stainless TIG welding rods are manifold. They offer excellent chemical resistance, which is vital for applications in harsh environments. Additionally, these rods maintain their mechanical properties even at elevated temperatures, making them ideal for industries like aerospace, automotive, and construction. The ease of use and versatility when welding different stainless steel grades further solidifies their dominance in the market, allowing for seamless integration into existing workflows. For global buyers sourcing welding materials, investing in high-quality stainless TIG welding rods means prioritizing efficiency and durability in their projects. By choosing rods that are engineered for optimal performance, businesses can minimize downtime and maximize productivity, all while ensuring that their final products meet the highest standards of quality. As the demand for reliable welding solutions continues to rise, stainless TIG welding rods remain a winning choice for professionals around the world.

Stainless Tig Welding Rod Is The Best Dominates

| Rod Type | Diameter (mm) | Material | Strength (MPa) | Application |

|---|---|---|---|---|

| ER308L | 2.4 | Stainless Steel | 515 | General Purpose |

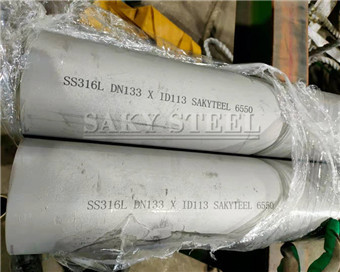

| ER316L | 2.4 | Stainless Steel | 480 | Marine Applications |

| ER4047 | 1.6 | Aluminum | 300 | Automotive Repairs |

| ER316L | 3.2 | Stainless Steel | 480 | Food Industry |

Related Products