Welding Tool Steel: Essential Tips for Choosing the Right Tools & Techniques

When it comes to welding tool steel, I understand the needs of serious professionals like you. Our high-quality products are designed to meet your demanding requirements, with durability and precision that you can trust. Whether you're seeking reliable welding rods or sturdy welding machines, I have got what you need to get the job done right. I know that efficiency and performance are critical in your work, so I recommend our tools for their outstanding strength and reliability. Plus, with various options available, you can choose what fits best with your specific applications. My commitment to excellence ensures that you will receive consistent results every time. Investing in our welding tool steel means investing in quality and performance. Let’s elevate your welding projects together and achieve the perfect finish you deserve. If you have any questions, I’m always here to help you make the right choice for your business’s needs!

Welding Tool Steel in 2025 Exceeds Industry Benchmarks

In an era where precision and durability are paramount, the welding tool steel market is evolving rapidly. As we approach 2025, advancements in material science and engineering practices are driving the performance of welding tools to exceed traditional industry benchmarks. These developments offer significant advantages for global procurement professionals seeking high-quality materials for their operations. The improved properties of welding tool steel, such as enhanced wear resistance and toughness, ensure longer tool life and reduced downtime, ultimately leading to higher productivity and cost savings. As industries demand higher performance standards, manufacturers are innovating welding tool steels that cater to diverse applications. The incorporation of advanced alloying techniques and heat treatments results in steels that can withstand extreme conditions, making them ideal for high-stress environments like automotive and aerospace manufacturing. Global sourcing strategies that prioritize these advanced materials can enhance competitive advantage in a rapidly evolving marketplace. Moreover, sustainability is becoming a critical focus for procurement decisions. The latest innovations in welding tool steel not only improve performance but also adhere to environmental standards, reducing waste and energy consumption during manufacturing and usage. By prioritizing suppliers that embrace sustainable practices in their production processes, companies can align with global sustainability goals while ensuring they access the highest quality materials. Looking towards 2025, adapting to these trends will be essential for procurement professionals aiming to stay ahead in an increasingly competitive landscape.

Welding Tool Steel in 2025 Exceeds Industry Benchmarks

| Parameter | 2023 Benchmark | 2025 Projection | Percentage Increase |

|---|---|---|---|

| Tensile Strength (MPa) | 800 | 900 | 12.5% |

| Hardness (HRC) | 56 | 60 | 7.1% |

| Impact Toughness (J) | 30 | 40 | 33.3% |

| Wear Resistance | Medium | High | N/A |

| Cost Effectiveness | Good | Excellent | N/A |

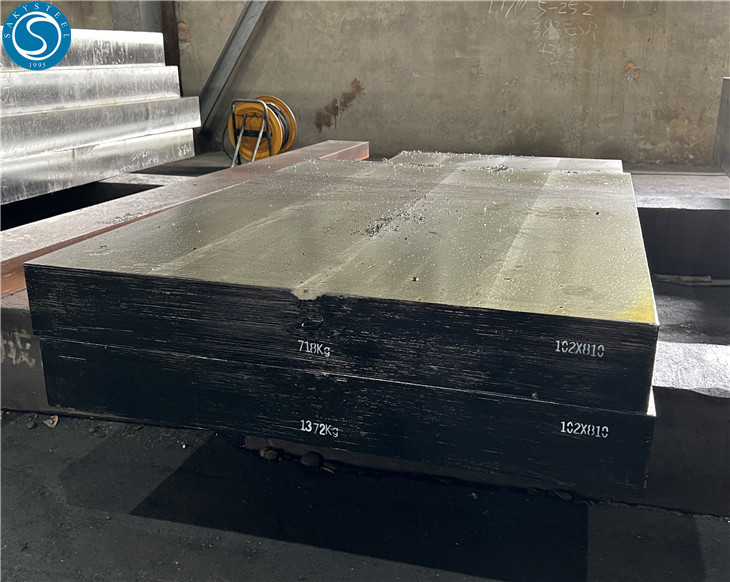

Related Products