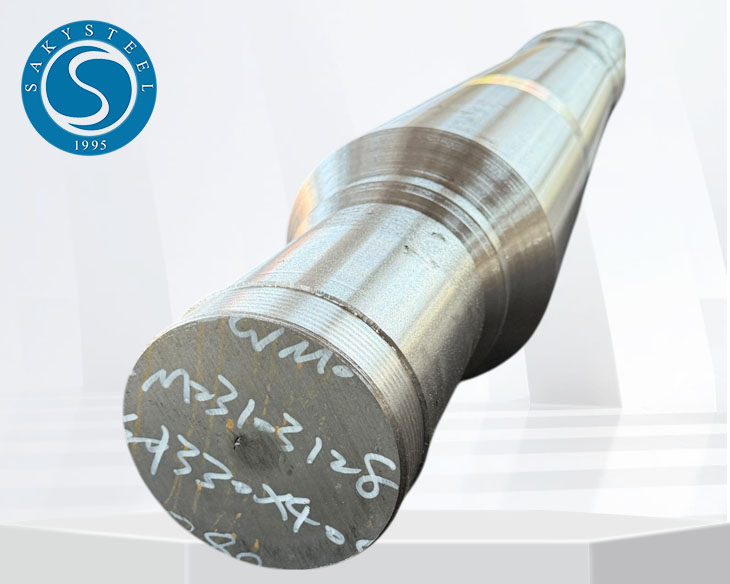

Shaft ea Forged ke Eng?

Shaft ea tšepe e entsoengke karolo ea tšepe ea cylindrical e entsoeng ka tšepe e kileng ea etsoa. Ho qhekella ho kenyelletsa ho bopa tšepe ka ho sebelisa matla a hatellang, hangata ka ho e futhumatsa mocheso o phahameng ebe o kenya khatello ka ho e otla ka hamore, ka ho e tobetsa kapa ka ho e bilika. Ts'ebetso ena e fella ka shaft e nang le lisebelisoa tse ntlafalitsoeng tsa mochini joalo ka matla a ntlafetseng, ho tiea, le ho hana ho apara ha ho bapisoa le li-shafts tse entsoeng ka tšepe kapa tšepe e entsoeng ka mochine.

Li-shafts tse entsoeng ka tšepe li sebelisoa haholo lits'ebetsong tse fapaneng tsa indasteri moo ts'ebetso e phahameng le ho tšoarella ho hlokahalang. Thepa ea tsona e phahameng ea mochini e li etsa hore li loketse ho sebelisoa maemong a boima, joalo ka lienjineri tsa makoloi, litsamaiso tsa sepakapaka, le metjhini e boima. Shaft e entsoeng ke karolo ea bohlokoa e sebelisoang lits'ebetsong tse ngata tsa indasteri, e tsebahalang ka matla a eona a ikhethang, ho tšoarella le ho tiea. Mofuta ona oa shaft o etsoa ka mokhoa o tsejoang e le ho forging, oo tšepe e bōpiloeng ka ho sebelisa matla a khatello e phahameng. Sehloohong sena, re tla hlahloba litšobotsi tsa bohlokoa le mokhoa oa ho etsa li-shafts tse entsoeng ka botlalo.

Litšobotsi tsa Litšiea tsa tšepe tse Fepisitsoeng

1. Matla a Phahameng:E 'ngoe ea melemo ea bohlokoa ka ho fetisisa ea li-shafts tse entsoeng ka tšepe ke matla a tsona a phahameng. Mokhoa oa ho theha o tsamaisana le sebopeho sa lijo-thollo tsa tšepe, ho etsa hore thepa e kopane le ho lekana. Sena se etsa hore ho be le shaft e hanyetsanang haholo le mokhathala le khatello ea kelello, haholo-holo tlas'a meroalo e phahameng le maemo a potolohang. Li-shafts tse entsoeng ka maiketsetso ha li na monyetla oa ho ba le bokooa bo kang porosity, bo ka hlahang likarolong tse entsoeng ka tšepe.

2.Matla a Ntlafetseng:Li-shafts tsa tšepe tse entsoeng ka maiketsetso li bontša ho tiea ho ntlafetseng. Ts'ebetso ea ho qhekella e theha thepa e ts'oanang e nang le mefokolo e fokolang ea kahare, e ntlafatsang khanyetso ea eona ho litšusumetso, mapetsong le mapheo. Sena se etsa hore li-shafts tsa tšepe tse entsoeng li loketse lits'ebetso moo karolo e ka bang tlas'a khatello ea maikutlo kapa matla a matla.

3.Keketseho ea ho tšoarella:Ka lebaka la matla a phahameng le ho tiea ho fanoang nakong ea ts'ebetso ea ho forging, li-shafts tsa tšepe tse entsoeng li atisa ho tšoarella nako e telele tlas'a maemo a ho senyeha le ho taboha. Haholo-holo ha li khone ho roala likhohlano 'me li ka boloka botšepehi ba tsona libakeng tse thata, e leng se etsang hore e be tse loketseng mechine e potolohang le lisebelisoa tse boima.

4.Ho hanyetsa Mokhathala:Ho hanyetsa mokhathala oa li-shafts tsa tšepe tse entsoeng ka tšepe ke e 'ngoe ea likarolo tsa bona tsa bohlokoa ka ho fetisisa. Forging e felisa li-voids tse ka hare tse ka fokolisang karolo, ka hona ho fokotsa kotsi ea ho hlōleha ho tloha meroalo ea cyclic. Sena se etsa hore li-shafts tsa tšepe tse hahelletsoeng e be tse loketseng ho sebelisoa lits'ebetsong tse nang le khatello e matla joalo ka likarolo tsa drivetrain le li-turbine shafts, tse kenang khafetsa nakong ea ts'ebetso.

5.Corrosion Resistance:Ho ipapisitsoe le alloy e ikhethileng e sebelisitsoeng ha ho etsoa (mohlala, tšepe e sa hloekang, tšepe ea alloy), lithapo tsa tšepe tse entsoeng ka tšepe li ka fana ka khanyetso e ntle ea kutu. Litšiea tse entsoeng ka thepa e sa jeng li ka mamella ho pepesehela mongobo, lik'hemik'hale le maemo a thata a tikoloho, e leng se etsang hore li tšoanelehe bakeng sa ho sebelisoa liindastering tse kang tsa metsing, tsa ho lokisa lik'hemik'hale le tsa matla.

Mefuta ea Li-Shafts tsa Tšepe tse Fepisitsoeng

1.Ho chesaMetsing ea Tšepe e Fepisitsoeng

Ha ho etsoa mocheso o chesang, tšepe e futhumatsoa ho mocheso ka holim'a ntlha ea eona ea recrystallization, hangata pakeng tsa 900 ° C le 1,300 ° C (1,650 ° F ho 2,370 ° F), ho lumella ho bopa habonolo. Ena ke mokhoa o tloaelehileng ka ho fetisisa oa ho etsa li-shafts tse kholo tsa tšepe, kaha o tiisa hore thepa e boloka matla le botšepehi nakong ea deformation. Hot forging e loketse ho hlahisa li-shafts tse boima tse sebelisoang liindastering tse kang likoloi, sefofane le kaho.

2.Cold Forged Steel Shafts

Mohatsela o batang o etsoa ka mocheso oa kamore kapa haufi le oona 'me hangata o fella ka thepa e matla haholo. Mokhoa ona o sebelisetsoa ho hlahisa lishafi tse nyane tse hlokang ho nepahala ha maemo a holimo, joalo ka tse sebelisoang mecheng e nepahetseng kapa likarolo tsa koloi. Li-shafts tse nang le serame hangata li matla 'me li na le bokaholimo bo betere ha li bapisoa le li-shafts tse chesitsoeng.

3.Isothermal Forged Steel Shafts

Ha ho etsoa isothermal, tšepe le die li bolokiloe ka mocheso o batlang o lekana nakong ea ts'ebetso. Mokhoa ona o fokotsa li-gradients tsa mocheso le ho netefatsa phallo ea thepa e ts'oanang, e lebisang ho thepa e ntle ea mochini. Isothermal forging e molemo haholo bakeng sa li-alloys tse sebetsang hantle tse sebelisoang sebakeng sa sefofane kapa lits'ebetsong tsa turbine.

Lits'ebetso tsa Mechini ea Tšepe e Forged

1.Indasteri ea Likoloi

Litšepe tse entsoeng ka tšepeli bohlokoa ho drivetrain, ho kenyeletsoa likarolo tse kang li-crankshafts, li-axles, li-drive shafts, le liphapang.

2.Indasteri ea Sefofane

Lefapheng la sepakapaka, litšepe tse entsoeng ka tšepe li sebelisoa lienjineng tsa turbine, lisebelisoa tse thellang, le likarolo tse ling tsa bohlokoa tse tlamehang ho sebetsa tlas'a mocheso o feteletseng le lebelo la ho potoloha.

3.Mechine e boima

Li-shafts tsa tšepe tse entsoeng ka tšepe li sebelisoa haholo mecheng e boima bakeng sa likarolo tse kang li-gear shafts, spindles le crankshafts.

4.Lekala la Matla

Litšepe tse entsoeng ka tšepe li sebelisoa ho li-turbine, lijenereithara le lisebelisoa tse ling tsa ho fehla matla.

5.Indasteri ea Marine

Li-shafts tsa tšepe tse entsoeng ka tšepe li sebelisoa ho li-propeller shafts, li-pump shafts le likarolo tse ling tsa leoatle.

6.Meepo le Kaho

Liindastering tse kang tsa merafo le tsa kaho, litšepe tse entsoeng ka tšepe li sebelisoa lisebelisoa tse kang li-crusher, conveyors le excavator.

Melemo ea ho Forged Steel Shafts Over Cast kapa Machined Shafts

1.Better Structural Integrity: Forging e felisa mefokolo ea ka hare joalo ka porosity, ho netefatsa hore li-shafts tsa tšepe tse entsoeng li na le mefokolo e fokolang ho feta likarolo tse entsoeng kapa tse entsoeng ka mochine.

2.Karolelano e phahameng ea matla ho boima ba 'mele: Li-shafts tse entsoeng ka tšepe tse entsoeng ka tšepe hangata li matla empa li le bobebe ho feta li-cast-casts, tse etsang hore li sebetse hantle likopong tse phahameng.

3.Mokhathala o ntlafetseng le ho hanyetsa ho apara: Mokhoa oa ho fereka o lumellana le sebopeho sa lijo-thollo, se matlafatsang bokhoni ba shaft ho mamella meroalo e pheta-phetoang le ho hanyetsa ho apara ho tloha ho khohlano.

4.Cost-Effective: Li-shafts tsa tšepe tse entsoeng ka tšepe li hloka tšenyo e fokolang ea thepa ha e bapisoa le ho lahla, e ka lebisang ho boloka litšenyehelo ka tlhahiso ea lihlahisoa tse ngata.

Nako ea poso: Dec-11-2024