Yintoni umngxuma owenziweyo?

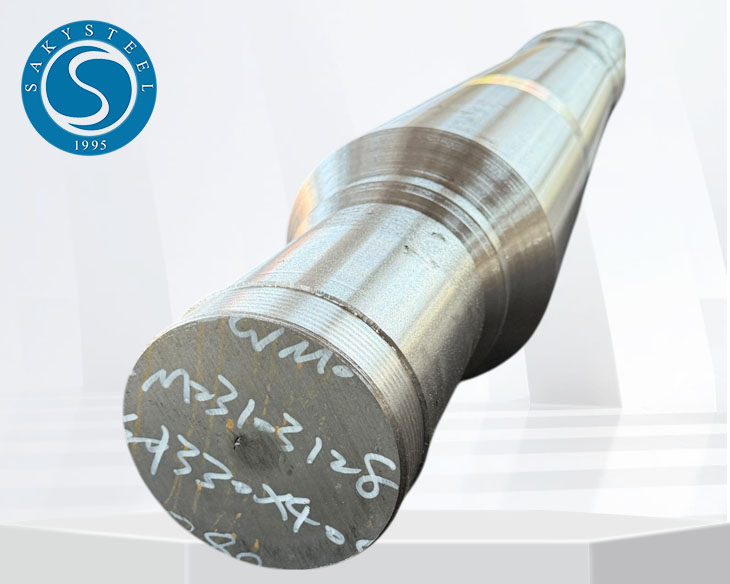

Ishaft yentsimbi eyenziweyoyinxalenye yentsimbi ye-cylindrical eyenziwe ngentsimbi eye yafumana inkqubo yokubumba. Ukubumba kubandakanya ukubumba isinyithi usebenzisa amandla acinezelayo, ngokuqhelekileyo ngokuyifudumeza kwiqondo lobushushu eliphezulu kwaye emva koko ufake uxinzelelo ngokuyibethelela, ukuyicofa okanye ukuyiqengqa. Le nkqubo ikhokelela kwi-shaft eneempawu eziphuculweyo zoomatshini ezifana nokomelela okuphuculweyo, ukuqina, kunye nokumelana nokunxiba xa kuthelekiswa neeshafti ezenziwe ngentsimbi etyhidiweyo okanye ngoomatshini.

I-shafts yensimbi eyenziweyo isetyenziswa ngokubanzi kwizicelo ezahlukeneyo zoshishino apho ukusebenza okuphezulu kunye nokuqina kubalulekile. Iipropathi zabo eziphezulu zoomatshini zibenza balungele ukusetyenziswa kwiindawo ezisingqongileyo, ezinje ngeenjini zeemoto, iisistim ze-aerospace, kunye noomatshini abanzima. Ishafti ekhutshiweyo licandelo elibalulekileyo elisetyenziswa kwimizi-mveliso emininzi, idume ngamandla ayo akhethekileyo, ukuqina, kunye nokuqina. Olu hlobo lwe-shaft lwenziwa ngenkqubo eyaziwa ngokuba yi-forging, apho isinyithi sibunjwa ngokufaka i-high-pressure forces. Kweli nqaku, siza kuphonononga iimpawu eziphambili kunye nenkqubo yokwenziwa kweeshafu ezibunjiweyo ngokweenkcukacha ngakumbi.

Iimpawu zeeShafti zeNtsimbi ezenziweyo

1.Amandla aphezulu:Enye yezona zinto zibalulekileyo eziluncedo kwiishafu zentsimbi ezibunjiweyo ngamandla azo aphezulu. Inkqubo yokuqulunqa ilungelelanisa isakhiwo sengqolowa yensimbi, okwenza izinto eziphathekayo zidibanise kwaye zifanane. Oku kubangela i-shaft ekwazi ukumelana nokudinwa kunye noxinzelelo, ngokukodwa phantsi kwemithwalo ephezulu kunye neemeko ezijikelezayo. Iishafti ezakhiweyo azifane zifumane iziphene ezifana ne-porosity, ezinokuthi zenzeke kwiindawo ezityhidiweyo.

2.Ukuphucula Ukuqina:Iishafu zentsimbi ezenziweyo zibonisa ukomelela okuphuculweyo. Inkqubo yokubumba idala i-homogenous material eneziphene ezimbalwa zangaphakathi, eziphucula ukuxhathisa kwayo kwiimpembelelo, iintanda, kunye nokwaphuka. Oku kwenza i-shafts yentsimbi ekhuniweyo ifaneleke kwizicelo apho icandelo linokuthi libe phantsi kokutshatyalaliswa okanye impembelelo ephezulu.

3.Ukonyuka koKuhlala ixesha elide:Ngenxa yamandla aphezulu kunye nokuqina okunikezelwa ngexesha lenkqubo yokubumba, i-shafts yentsimbi eyenziweyo ihlala ixesha elide phantsi kweemeko zokuguga kunye nokukrazula. Ziyakwazi ukuxhathisa ngokukodwa ukunxiba kwi-friction kwaye ziyakwazi ukugcina ingqibelelo yazo kwiimeko ezinzima, zibenze zilungele umatshini ojikelezayo kunye nezicelo ezinzima.

4.Ukumelana nokuFatigue:Ukumelana nokukhathala kweeshafu zentsimbi ezibunjiweyo yenye yezona zinto zibalulekileyo. Ukuqulunqa kuphelisa i-voids yangaphakathi enokuthi yenze buthathaka inxalenye, ngaloo ndlela inciphisa umngcipheko wokungaphumeleli kwimithwalo ye-cyclic. Oku kwenza ukuba iishafti zentsimbi ezibunjiweyo zilungele ukusetyenziswa kuxinzelelo oluphezulu lwezixhobo ezifana nezixhobo zedrivetrain kunye neeshafti zeinjini yomoya, ezityhutyha ngokuphindaphindiweyo ukulayisha ngexesha lokusebenza.

5.UKuxhathisa iCorrosion:Ngokuxhomekeke kwi-alloy ethile esetyenzisiweyo kwinkqubo yokubumba (umzekelo, insimbi engenasici, intsimbi ye-alloy), i-shafts yentsimbi ekhuniweyo inokunika ukuxhathisa okugqwesileyo. Iishafu zentsimbi ezenziwe ngezinto ezikwaziyo ukumelana nomhlwa ziyakwazi ukumelana nokuchanabeka kubumanzi, imichiza, kunye neemeko ezirhabaxa zokusingqongileyo, zizenza zilungele ukusetyenziswa kwimizi-mveliso efana neyaselwandle, yokulungisa imichiza namandla.

Iindidi zeeShafti zentsimbi ezibunjiweyo

1.HotIiShafti zentsimbi ezibunjiweyo

Kwi-forging eshushu, intsimbi ifudumala kwiqondo lokushisa ngaphezu kwendawo yayo yokuvuselela, ngokuqhelekileyo phakathi kwe-900 ° C ukuya kwi-1,300 ° C (1,650 ° F ukuya kwi-2,370 ° F), ukuvumela ukubunjwa lula. Le yeyona ndlela ixhaphakileyo yokubumba i-shafts enkulu yensimbi, njengoko iqinisekisa ukuba izinto eziphathekayo zigcina amandla kunye nokunyaniseka ngexesha lokuguqulwa. I-Hot forging ilungele ukuvelisa iishafti ezinzima ezisetyenziswa kumashishini afana neemoto, i-aerospace, kunye nokwakha.

2.Ii-Cold Forged Steel Shafts

Ukubunjwa okubandayo kwenziwa kwindawo okanye kufutshane nobushushu begumbi kwaye ngokuqhelekileyo kubangela ukuba kubekho izinto ezinamandla kakhulu. Inkqubo isetyenziselwa ukuvelisa iishafti ezincinci ezifuna ukuchaneka okuphezulu kwe-dimensional, njengaleyo isetyenziswe kumatshini ochanekileyo okanye kwizinto zemoto. Iishafti ezibandayo zisoloko zomelele kwaye zinomphezulu ongcono xa zithelekiswa neeshafti ezishushu.

3.Ii-Isothermal Forged Steel Shafts

Kwi-isothermal forging, zombini isinyithi kunye ne-die zigcinwa kubushushu obufanayo ngexesha lenkqubo. Le ndlela inciphisa i-gradients ye-thermal kwaye iqinisekisa ukuhamba kwezinto ezifanayo, okukhokelela kwiimpawu ezingcono zomatshini. I-Isothermal forging iluncedo kakhulu kwi-alloys ephezulu yokusebenza esetyenziswa kwi-aerospace okanye izicelo ze-injini yomoya.

Ukusetyenziswa kweeShafti zeNtsimbi ezenziweyo

1.Ushishino lweemoto

Iishafu zentsimbi ezenziweyozibalulekile kwi-drivetrain, kubandakanywa amacandelo afana ne-crankshafts, i-axles, i-drive shafts, kunye nokwahluka.

2.Ishishini le-Aerospace

Kwicandelo le-aerospace, i-shafts yentsimbi eyenziweyo isetyenziselwa iinjini ze-turbine, izixhobo zokumisa, kunye nezinye iindawo ezibalulekileyo ekufuneka zisebenze phantsi kobushushu obugqithisileyo kunye nezantya zokujikeleza.

3. oomatshini abanzima

Iishafu zentsimbi ezakhiweyo zisetyenziswa kakhulu koomatshini abanzima kumacandelo anje ngeeshafu zegiya, ii-spindles, kunye nee-crankshafts.

4.ICandelo lezaMandla

Iishafu zentsimbi ezibunjiweyo zisetyenziswa kwiiinjini zomoya, iijenereyitha, kunye nezinye izixhobo zokuvelisa amandla.

5.Ishishini laseLwandle

Iishafu zentsimbi ezenziweyo zisetyenziswa kwi-propeller shafts, i-pump shafts, kunye nezinye izinto zaselwandle.

6.Imigodi kunye noKwakha

Kumashishini afana nemigodi kunye nokwakha, iishafti zentsimbi ezibunjiweyo zisetyenziswa kwizixhobo ezifana nezityumzayo, iiconveyors, kunye nabembi.

Izinto eziluncedo kwi-Forged Steel Shafts Over Cast or Machined Shafts

1.I-Better Structural Integrity: Ukuqulunqwa kuphelisa iziphene zangaphakathi ezifana ne-porosity, ukuqinisekisa ukuba i-shafts yentsimbi ekhutshiweyo inobuthathaka obuncinci kuneendawo ezityhidiweyo okanye ezinomatshini.

I-2.I-Higher Strength-to-Weight Ratio: I-shafts yensimbi eyenziweyo ihlala yomelele kodwa ilula ngakumbi kuneengqungquthela ze-cast, ezenza zisebenze ngakumbi kwizicelo eziphezulu zokusebenza.

3.Ukukhathala okuPhuculweyo kunye nokuNxitywa kweNgqoko: Inkqubo yokubumba ilungelelanisa isakhiwo sengqolowa yezinto eziphathekayo, ephucula amandla e-shaft yokumelana nemithwalo ephindaphindiweyo kunye nokuchasana nokugqoka kwi-friction.

I-4.I-Cost-Efficiency: I-shafts yensimbi eyenziweyo ifuna ukuchithwa kwezinto ezincinci xa kuthelekiswa nokuphosa, oku kunokukhokelela ekugcinweni kweendleko kwimveliso ephezulu.

Ixesha lokuposa: Dec-11-2024