Iyini i-Forged Shaft?

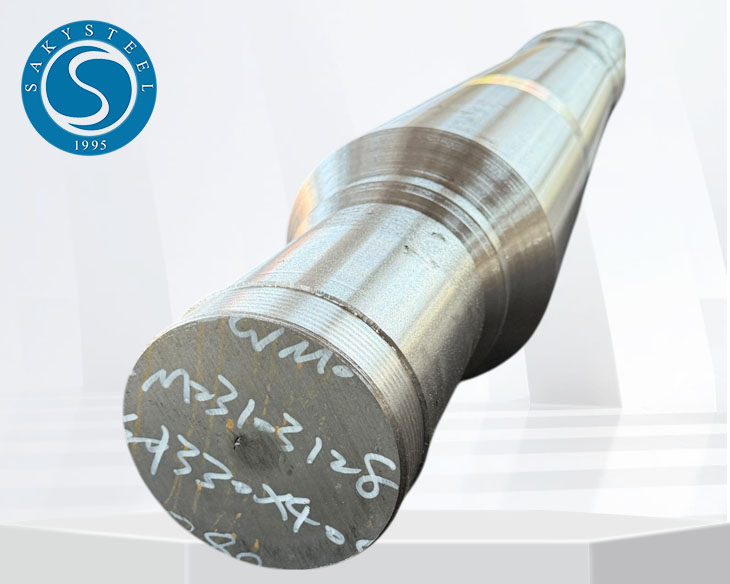

Ishaft yensimbi eyenziwe ngomgunyathiiyingxenye yensimbi eyi-cylindrical eyenziwe ngensimbi eye yabhekana nenqubo yokubumba. Ukubumba kuhlanganisa ukubumba insimbi usebenzisa amandla acindezelayo, ngokuvamile ngokuyifudumeza ezingeni lokushisa eliphezulu bese usebenzisa ingcindezi ngokuyishaya ngesando, ngokuyicindezela, noma ngokuyigingqa. Le nqubo iholela ku-shaft enezici zemishini ezithuthukisiwe ezifana namandla athuthukisiwe, ukuqina, nokumelana nokuguga uma kuqhathaniswa namashafu enziwe ngensimbi ewugqinsi noma ngomshini.

Amashafu ensimbi akhiwe asetshenziswa kabanzi ezinhlelweni ezahlukahlukene zezimboni lapho ukusebenza okuphezulu nokuqina kubalulekile. Izakhiwo zazo ezisezingeni eliphezulu zokuwalungisa zizenza zilungele ukusetshenziswa ezindaweni ezinzima, njengezinjini zezimoto, izinhlelo ze-aerospace, nemishini esindayo. Ishafu engumgunyathi iyingxenye ebalulekile esetshenziswa ezimbonini eziningi, edume ngamandla ayo angavamile, ukuqina, nokuqina. Lolu hlobo lwe-shaft lwenziwa ngenqubo eyaziwa ngokuthi i-forging, lapho insimbi yakheka khona ngokusebenzisa amandla okucindezela okuphezulu. Kulesi sihloko, sizohlola izici ezibalulekile kanye nenqubo yokukhiqiza yama-shaft akhiwe ngokuningiliziwe.

Izici Zezinsimbi Zensimbi Ezenziwayo

1. Amandla Aphakeme:Enye yezinzuzo ezibaluleke kakhulu zamashafu ensimbi akhiwe amandla awo aphezulu. Inqubo yokubumba iqondanisa ukwakheka kwensimbi okusanhlamvu, okwenza impahla ihlangane futhi ifane. Lokhu kubangela i-shaft ekwazi ukumelana nokukhathala nokucindezeleka, ikakhulukazi ngaphansi kwemithwalo ephezulu kanye nezimo ezijikelezayo. Amashafti afojiwe mancane amathuba okuthi ahlangabezane nokukhubazeka okufana ne-porosity, okungenzeka ezingxenyeni ezikhonjiwe.

2.Ukuqina Okuthuthukisiwe:Amashafu ensimbi akhiwe abonisa ukuqina okuthuthukisiwe. Inqubo yokubumba idala into efana ne-homogenous enamaphutha ambalwa angaphakathi, okuthuthukisa ukumelana kwayo nemithelela, imifantu, nokuphuka. Lokhu kwenza amashafu ensimbi afojiwe afanelekele izinhlelo zokusebenza lapho ingxenye ingase ibe ngaphansi kokushaqeka noma amandla omthelela omkhulu.

3.Ukuqina Okukhulisiwe:Ngenxa yamandla aphezulu kanye nokuqina okunikezwayo phakathi nenqubo yokubumba, amashafu ensimbi akhiwe ajwayele ukuhlala isikhathi eside ngaphansi kwezimo zokuguga nokudabuka. Ziyakwazi ukumelana ikakhulukazi nokuguquguquka futhi zingagcina ubuqotho bazo ezindaweni ezinokhahlo, zizenze zilungele imishini ejikelezayo kanye nezinhlelo zokusebenza ezinzima.

4.Ukumelana nokukhathala:Ukumelana nokukhathala kwamashafu ensimbi akhiwe kungenye yezici zabo ezibucayi kakhulu. I-Forging iqeda i-voids yangaphakathi engenza ingxenye ethile ibe buthaka, ngaleyo ndlela inciphise ingozi yokwehluleka emithwalweni yama-cyclic. Lokhu kwenza amashafu ensimbi akhiwe alungele ukusetshenziswa ezinhlelweni ezinengcindezi ephezulu njengezingxenye ze-drivetrain nama-turbine shafts, alayishwa ngokuphindaphindiwe ngesikhathi sokusebenza.

5.Ukumelana Nokugqwala:Ngokuya ngengxubevange ethile esetshenziswa enqubweni yokubumba (isb., insimbi engagqwali, insimbi eyingxubevange), izinti zensimbi ezibunjiwe zinganikeza ukumelana nokugqwala okuhle kakhulu. Amashafu ensimbi enziwe ngezinto ezimelana nokugqwala akwazi ukumelana nokuchayeka kumswakama, amakhemikhali, nezimo zemvelo ezinzima, okuwenza afanelekele ukusetshenziswa ezimbonini ezifana nasolwandle, ukucubungula amakhemikhali namandla.

Izinhlobo Zezinsimbi Zensimbi Ezenziwayo

1.OkushisaIzikhonkwane Zensimbi Ezenziwa

Ekwenziweni okushisayo, insimbi ishiselwa ezingeni lokushisa elingaphezu kwendawo yayo yokuvuselela ikristalu, ngokuvamile phakathi kuka-900°C kuya ku-1,300°C (1,650°F kuya ku-2,370°F), ukuze kuvunyelwe ukubunjwa kalula. Lena indlela evame kakhulu yokwenza ama-shafts ensimbi amakhulu, njengoba iqinisekisa ukuthi impahla igcina amandla nobuqotho ngesikhathi sokuguqulwa. I-Hot Forging ilungele ukukhiqiza izinsimbi ezisindayo ezisetshenziswa ezimbonini ezifana nezezimoto, i-aerospace, kanye nezokwakha.

2.Cold Forged Steel Shafts

Ukufoja okubandayo kwenziwa endaweni yokushisa yegumbi noma eduze nayo futhi ngokuvamile kuholela kokubalulekile okunamandla aphezulu. Inqubo isetshenziselwa ukukhiqiza amashafu amancane adinga ukunemba okuphezulu kobukhulu, njengalawo asetshenziswa emishinini enembayo noma ezintweni zezimoto. Amashafti aqandayo avame ukuba namandla futhi abe nesiphetho esingcono uma kuqhathaniswa namashafu afojiwe ashisayo.

3.I-Isothermal Forged Steel Shafts

Ekwakhekeni kwe-isothermal, kokubili insimbi kanye ne-die kugcinwa cishe ezingeni lokushisa elifanayo ngesikhathi senqubo. Le ndlela inciphisa ama-gradients ashisayo futhi iqinisekisa ukugeleza kwezinto ezifanayo, okuholela ezintweni ezingcono zemishini. I-Isothermal forging inenzuzo ikakhulukazi kuma-alloys asebenza kahle kakhulu asetshenziswa kwi-aerospace noma izinhlelo zokusebenza ze-turbine.

Izicelo ze-Forged Steel Shafts

1.Imboni Yezimoto

Izinsimbi zensimbi ezakhiwezibalulekile ku-drivetrain, okuhlanganisa izingxenye ezifana nama-crankshafts, ama-axles, ama-drive shafts, nokuhluka.

2.Imboni ye-Aerospace

Emkhakheni we-aerospace, amashafu ensimbi akhiwe asetshenziswa ezinjinini zomoya, igiya lokuhlala, nezinye izingxenye ezibalulekile okufanele zisebenze ngaphansi kwamazinga okushisa aphakeme kanye nesivinini sokuzungeza.

3.Imishini Enzima

Amashafu ensimbi akhiwe asetshenziswa kakhulu emishinini esindayo yezingxenye ezinjengama-giya shafts, ama-spindles, nama-crankshafts.

4.Umkhakha wezaMandla

Amashafu ensimbi akhiwe asetshenziswa kuma-turbines, amajeneretha, nezinye izinto zokuphehla ugesi.

5.Imboni Yasolwandle

Amashafu ensimbi akhiwe asetshenziswa kuma-propeller shafts, ama-pump shafts, nezinye izinto zasolwandle.

6.Izimayini kanye Nokwakha

Ezimbonini ezifana nezimayini nezokwakha, amashafu ensimbi akhiwe asetshenziswa ezintweni ezinjengama-crusher, ama-conveyors, nama-excavators.

Izinzuzo zamaShafti Ensimbi Efojiwe Ngaphezulu Kwe-Cast noma Izigxobo Esenziwe Ngomshini

1.Better Structural Integrity: Forging iqeda ukukhubazeka kwangaphakathi okufana ne-porosity, iqinisekisa ukuthi amashafu ensimbi afojiwe anobuthakathaka obumbalwa kunezingxenye ezikhonjiwe noma ezenziwe ngomshini.

2.I-Higher Strength-to-weight Ratio: Amashafu ensimbi afojiwe avame ukuba namandla kodwa abe lula kunozakwethu, okuwenza asebenze kahle kakhulu ekusetshenzisweni kokusebenza okuphezulu.

3.Ukukhathala Okuthuthukisiwe Nokumelana Nokugqoka: Inqubo yokubumba iqondanisa ukwakheka kokusanhlamvu kwezinto ezibonakalayo, okuthuthukisa ikhono le-shaft lokukwazi ukumelana nemithwalo ephindaphindayo kanye nokumelana nokuguga ngenxa yokungqubuzana.

I-4.I-Cost-Efficiency: Imishini yensimbi eyakhiwe idinga ukumosheka kwempahla encane uma kuqhathaniswa nokuphonsa, okungaholela ekongeni kwezindleko ekukhiqizeni umthamo ophezulu.

Isikhathi sokuthumela: Dec-11-2024