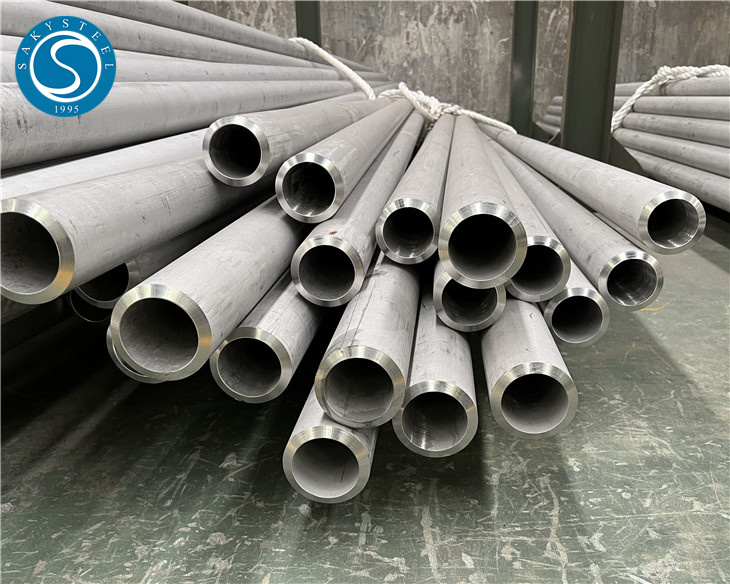

Premium 1 3 4 Stainless Steel Tubing for Durable Projects & Applications

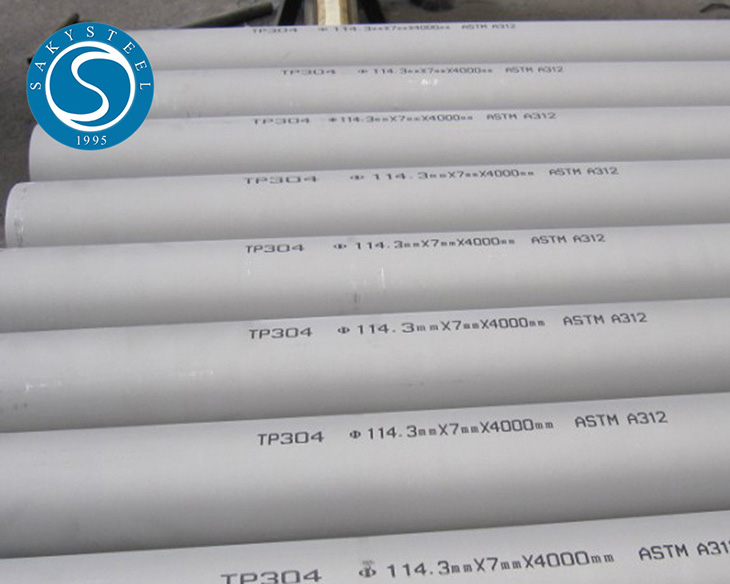

When I think about reliable materials for projects, {1 3 4 Stainless Steel Tubing} always comes to mind. It’s perfect for a range of applications, thanks to its durability and resistance to corrosion. If you're involved in manufacturing or construction, you know how important it is to source high-quality tubing that meets industry standards. I find that this tubing not only provides excellent structural support but also enhances the overall look of any finished product. Whether I’m fabricating custom furniture or structural components, the versatility of this stainless steel tubing ensures I can tackle various designs without compromising on quality. Plus, I appreciate the ease of maintenance it offers, saving time and costs in the long run. When searching for trusted suppliers, knowing the right specs like size and finish can make all the difference. Trust me, investing in {1 3 4 Stainless Steel Tubing} is a decision you won’t regret making for your next project!

1 3 4 Stainless Steel Tubing Manufacturer Manufacturers You Can Rely On

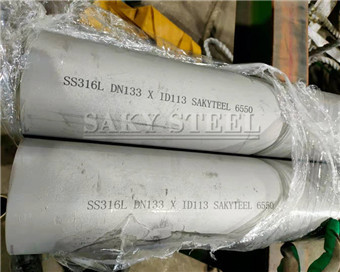

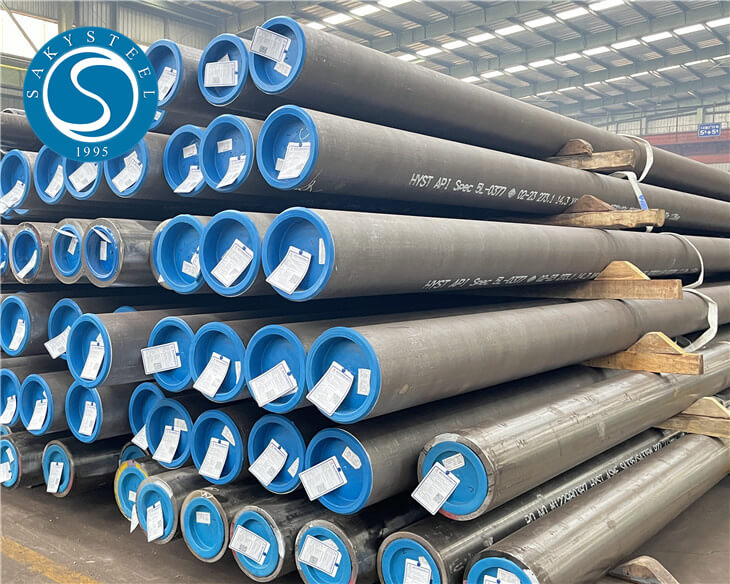

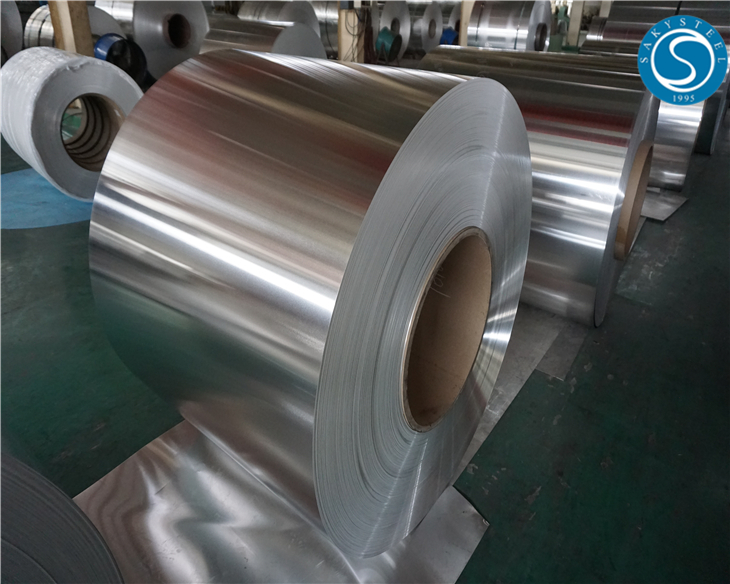

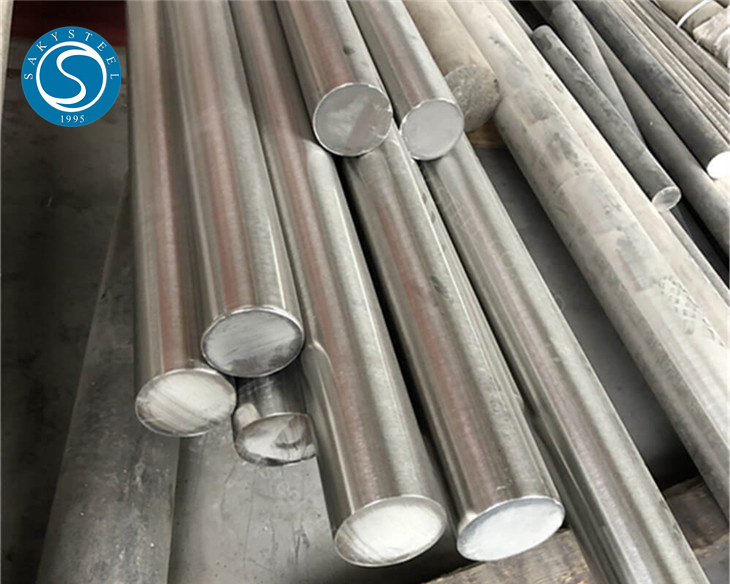

When it comes to sourcing reliable stainless steel tubing, understanding the manufacturing process and quality standards is crucial for global buyers. Stainless steel tubing is widely used across various industries due to its corrosion resistance, strength, and versatility. Whether you are in construction, automotive, or medical sectors, finding a trusted manufacturer ensures you receive high-quality products that meet your specific needs. A reputable manufacturer should offer a variety of stainless steel tubing options, including 1, 3, and 4-inch diameters, catering to different applications. It’s essential to look for certifications and adherence to international standards, as this guarantees that the products have undergone rigorous testing for mechanical properties, surface finish, and durability. Furthermore, a manufacturer’s experience and production capabilities can provide insights into their reliability and consistency in delivering products that meet the market demands. Sustainable practices are also becoming vital in the manufacturing industry. Many reputable suppliers are increasingly focusing on environmentally friendly production methods, reducing waste, and utilizing recyclable materials. By partnering with a manufacturer that prioritizes sustainability, global buyers not only contribute to a healthier planet but also enhance their own corporate responsibility initiatives. In conclusion, choosing the right stainless steel tubing manufacturer involves evaluating quality, experience, certification, and sustainability practices to ensure you make an informed decision that aligns with your business goals.

1 3 4 Stainless Steel Tubing Manufacturer Manufacturers You Can Rely On

| Manufacturer Type | Material Grade | Tube Diameter (inches) | Wall Thickness (inches) | Length Options (feet) |

|---|---|---|---|---|

| Seamless | 304 | 1.5 | 0.120 | 20, 30, 40 |

| Welded | 316L | 2.0 | 0.065 | 10, 20, 30 |

| Specialty | Duplex | 1.25 | 0.095 | 15, 25, 50 |

| Coated | TP321 | 3.0 | 0.150 | 20, 40 |

Related Products