Top 10 Stainless Steel Pipe Options for Quality and Durability

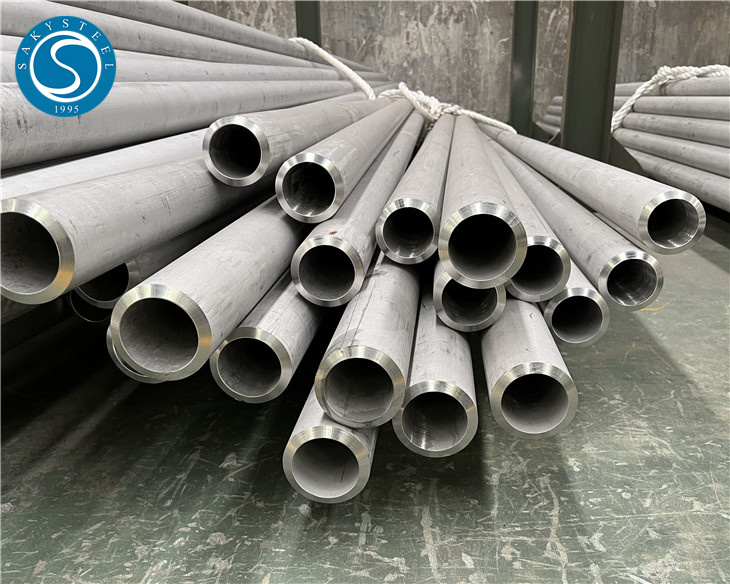

When sourcing high-quality materials, I found that our 10 Stainless Steel Pipe stands out for its durability and versatility. As a B2B purchaser, I appreciate how this pipe suits a wide range of applications, from construction to manufacturing. I’ve noticed that its resistance to corrosion and excellent weldability make it an ideal choice for long-lasting projects. I always consider factors like pricing and inventory when making decisions, and I can assure you that our competitive pricing and reliable supply chain simplify the purchasing process. The stainless steel construction not only ensures strength but also enhances aesthetic appeal—perfect for both visible and hidden installations. Whether you're looking to replace old pipes or starting a new project, our 10 Stainless Steel Pipe consistently meets industry standards, making it a trusted solution for professionals like us. Let’s elevate your projects together with quality materials that deliver performance and reliability every time.

10 Stainless Steel Pipe Where Innovation Meets 2025 Custom Solutions,

In the ever-evolving landscape of manufacturing and industrial solutions, stainless steel pipes play a pivotal role, especially as we approach 2025. With increasing demands for custom solutions, innovative designs, and sustainable practices, stainless steel products have become a central element in various industries, from construction to automotive. The versatility of stainless steel pipes, combined with advancements in technology and engineering, allows for the creation of tailored products that meet specific needs while maintaining quality and durability. As we focus on the future, the emphasis on innovation is clear. Customization in sizes, shapes, and specifications ensures that businesses can find exactly what they need without compromising on performance. Enhanced corrosion resistance, improved structural integrity, and eco-friendly manufacturing processes are driving the market forward. Additionally, technological advancements in production methods, such as 3D printing and precision machining, enable manufacturers to push the boundaries of design and functionality, resulting in superior products that cater to unique applications. Global procurement trends highlight a growing preference for suppliers that can provide not only exceptional quality but also responsive customer service and rapid delivery. As industries increasingly rely on stainless steel pipes for their operational needs, choosing the right partner is vital. By prioritizing innovative solutions and customization, businesses can ensure they meet the challenges and demands of tomorrow's market while achieving sustainability goals.

10 Stainless Steel Pipe Where Innovation Meets 2025 Custom Solutions

| Pipe ID | Material Grade | Diameter (mm) | Wall Thickness (mm) | Length (m) | Application | Custom Features |

|---|---|---|---|---|---|---|

| SP-001 | 316L | 50 | 3 | 6 | Chemical Processing | Corrosion Resistant Coating |

| SP-002 | 304 | 76 | 4 | 12 | Food Processing | FDA Compliant Finish |

| SP-003 | Duplex 2205 | 100 | 5 | 10 | Marine Applications | Seawater Resistant |

| SP-004 | 321 | 64 | 2.5 | 8 | Oil & Gas | High Temperature Resistance |

| SP-005 | 904L | 32 | 2 | 5 | Pharmaceutical | Hygienic Design |

| SP-006 | S31803 | 150 | 6.5 | 15 | Power Generation | Excellent Strength |

| SP-007 | 430 | 40 | 3 | 20 | Architecture | Aesthetic Finish |

| SP-008 | 201 | 25 | 1.5 | 7 | Furniture | Lightweight Design |

| SP-009 | Hastelloy C276 | 80 | 4 | 10 | Aerospace | Extreme Corrosion Resistance |

| SP-010 | Inconel 625 | 150 | 5 | 20 | Nuclear Power | Heat and Oxidation Resistance |

Related Products