Premium 2 X 2 Stainless Steel Tubing for Durable Fabrication Needs

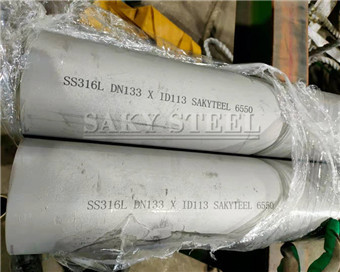

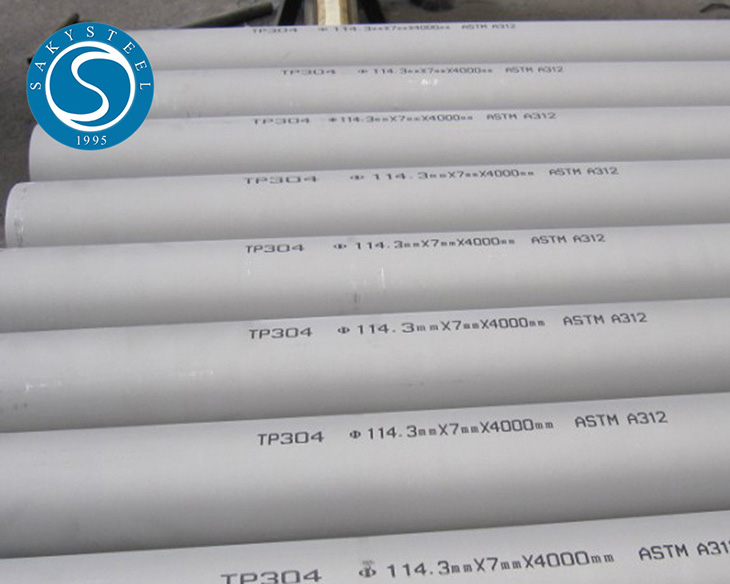

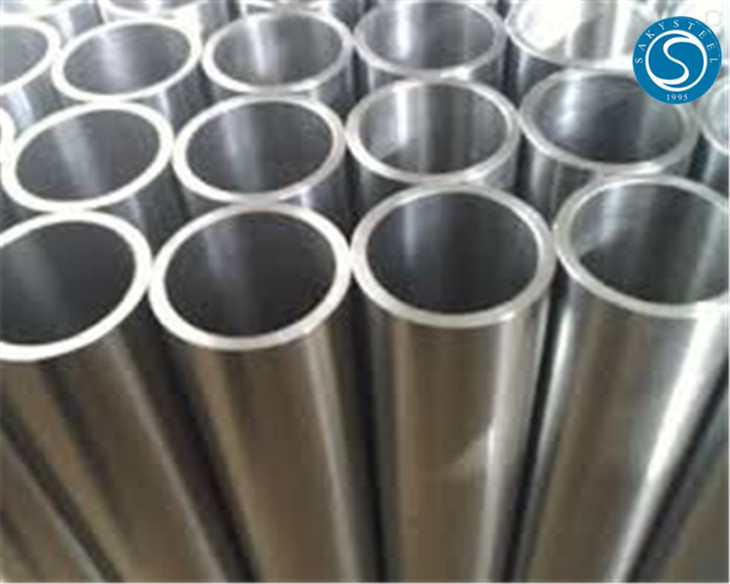

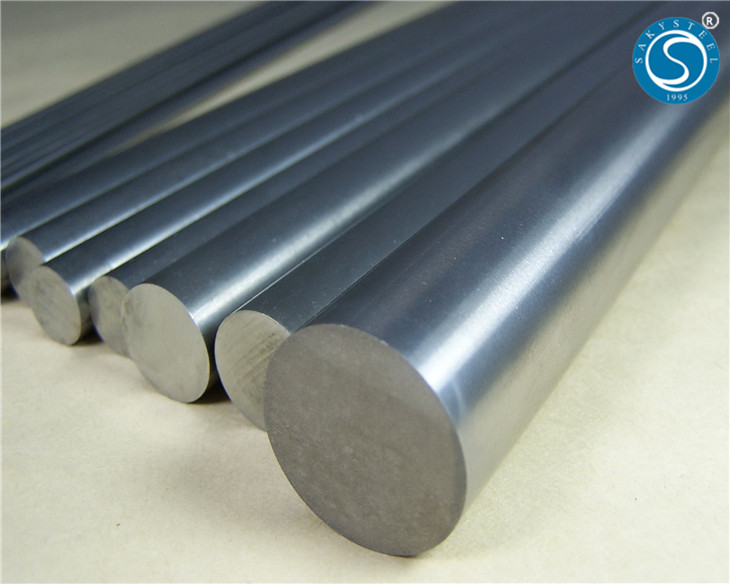

When I first learned about the versatility of 2 x 2 stainless steel tubing, I knew it was a must-have for my projects. Whether it’s for structural support, framing, or custom fabrication, this tubing holds up against corrosion and offers remarkable strength. As a B2B purchaser, I appreciate how durable and lightweight it is, making it easy to work with yet strong enough for heavy-duty applications. With a smooth finish and precision dimensions, this tubing ensures a flawless fit in any setup. It's perfect for industries like construction, automotive, and manufacturing. Plus, I value the ability to customize lengths and grades to suit specific needs—it's all about efficiency! When considering quality and performance, 2 x 2 stainless steel tubing stands out, making it an intelligent choice for any business looking to elevate their projects. Don't miss out on the benefits this product can bring to your operations.

2 X 2 Stainless Steel Tubing Factory Pioneers in the Field

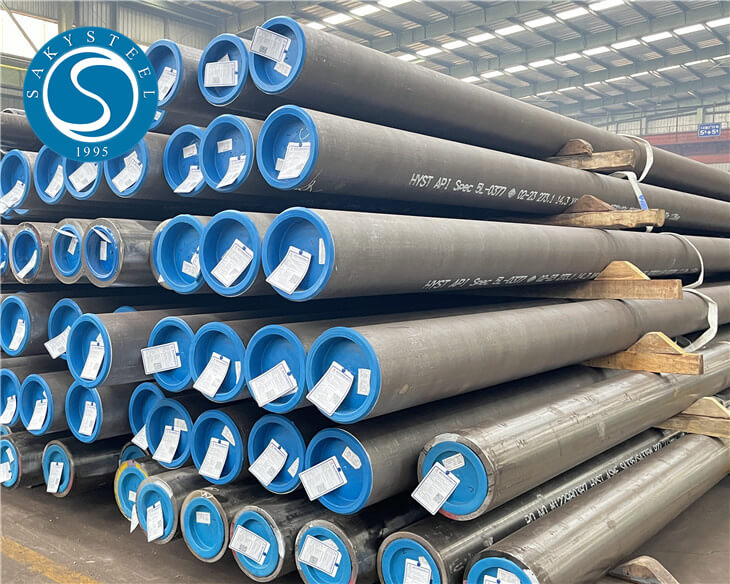

In the competitive landscape of metal manufacturing, 2x2 stainless steel tubing stands out for its versatility and strength. As pioneers in the field, we have honed our capabilities to produce high-quality stainless steel tubing that meets diverse industry needs. Our commitment to innovation and excellence ensures that our products are not only durable but also tailored to customer specifications, making us a preferred supplier for global purchasers. The advantages of utilizing 2x2 stainless steel tubing are manifold, including resistance to corrosion, lightweight properties, and ease of fabrication. These features make it an ideal choice for applications in construction, automotive, and various industrial sectors. With state-of-the-art facilities and a skilled workforce, we are equipped to handle orders of all sizes while adhering to stringent quality control measures. Our focus on sustainability also ensures that our manufacturing processes are environmentally friendly, reflecting the increasing demand for responsible sourcing in today's market. Partnering with us means accessing not just a product, but a reliable service tailored to your operational needs. We understand the urgency in procurement and strive to expedite delivery without compromising quality. Our dedicated team is always available to assist, ensuring that your experience is seamless from inquiry to delivery. Explore the benefits of working with seasoned experts in stainless steel tubing and enhance your project's success with our top-tier solutions.

2 X 2 Stainless Steel Tubing Factory Pioneers in the Field

| Dimension | Material Grade | Finish Type | Application | Production Capacity (tons/year) |

|---|---|---|---|---|

| 2" x 2" | 304 | Polished | Construction | 500 |

| 2" x 2" | 316 | Brushed | Marine | 300 |

| 2" x 2" | 430 | Passivated | Automotive | 400 |

| 2" x 2" | 201 | Mill Finish | Furniture | 350 |

| 2" x 2" | 430 | Electropolished | Food Processing | 600 |

Related Products