304 Stainless Steel Tig Rod: Reliable Performance for Your Welding Needs

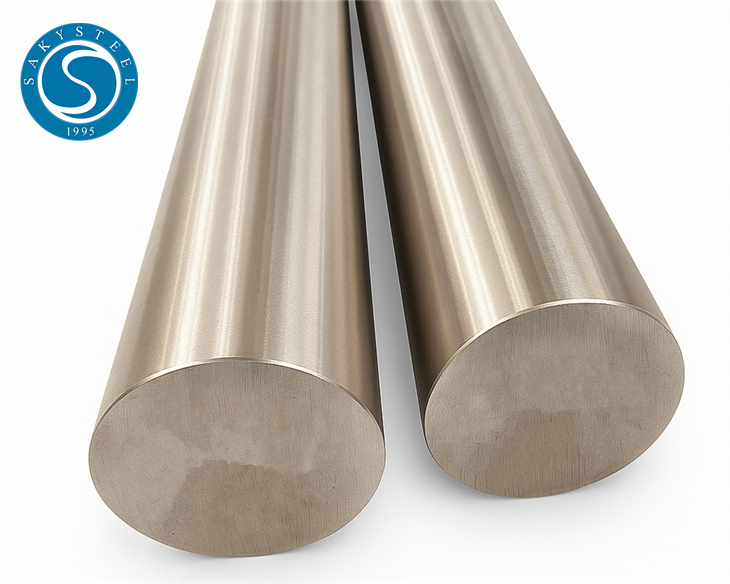

When I think about the durability and performance of welding materials, the 304 Stainless Steel Tig Rod stands out. It’s perfect for those seeking high-quality solutions for their fabrication needs. Whether you’re tackling food processing equipment or architectural applications, this rod delivers excellent corrosion resistance and weldability. I often hear from B2B purchasers that the right materials make a huge difference in project outcomes. This rod not only meets those expectations but exceeds them with its versatility. It’s easy to use and ensures top-notch welds every time, saving both time and resources. Plus, its competitive pricing makes it an attractive option for bulk buyers. If you're in the market for reliable fillers that won’t let you down, this is the choice I thoroughly recommend. Let’s make your next project a success with 304 Stainless Steel Tig Rod – quality you can trust!

304 Stainless Steel Tig Rod Application Outperforms the Competition

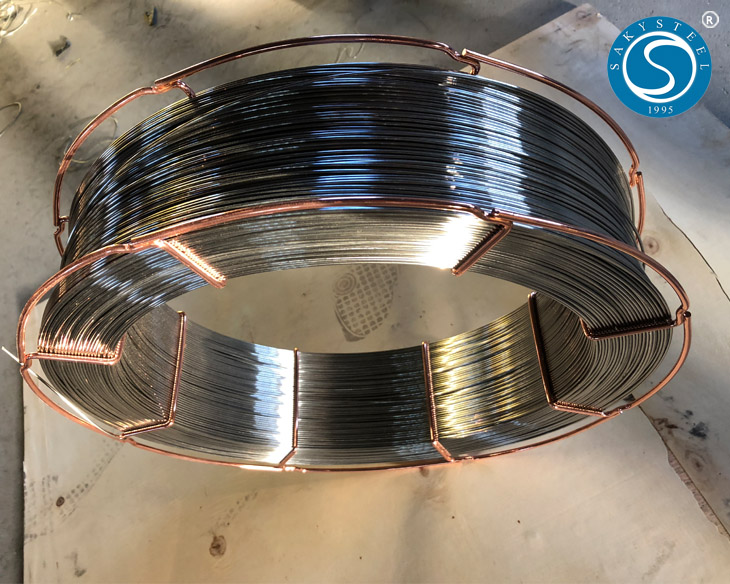

When it comes to welding applications, the choice of filler materials can significantly influence the quality and performance of the final product. Among these, the 304 stainless steel TIG (tungsten inert gas) rod stands out due to its exceptional properties and versatility. Renowned for its corrosion resistance and strength, the 304 stainless steel is a preferred choice for a variety of industries, including food processing, chemical manufacturing, and marine applications. The superior performance of 304 TIG rods allows for precision welding, ensuring strong and durable welds that can withstand harsh environments. One of the key advantages of 304 stainless steel TIG rods is their ease of use. They are designed for seamless application, providing welders with a smooth and consistent feed rate, which reduces the risk of defects during the welding process. Additionally, these rods maintain their integrity at high temperatures, making them ideal for situations where heat resistance is crucial. The superior mechanical properties of 304 stainless steel also mean that the finished welds exhibit excellent toughness and resilience, outperforming competitors in rigorous testing scenarios. In a global market with diverse requirements, sourcing high-quality materials is essential for maintaining competitive advantage. The consistent performance, reliability, and versatility of 304 stainless steel TIG rods not only meet but exceed industry standards, offering manufacturers an edge in their respective fields. By investing in these top-tier materials, businesses can enhance their production processes, ensuring that their products are not only durable but also able to meet the evolving demands of the market.

304 Stainless Steel Tig Rod Application Outperforms the Competition

| Application | Features | Advantages | Typical Industries |

|---|---|---|---|

| Welding | Corrosion Resistance, High Temperature Resistance | Durability, Long Service Life | Food Processing, Chemical Processing |

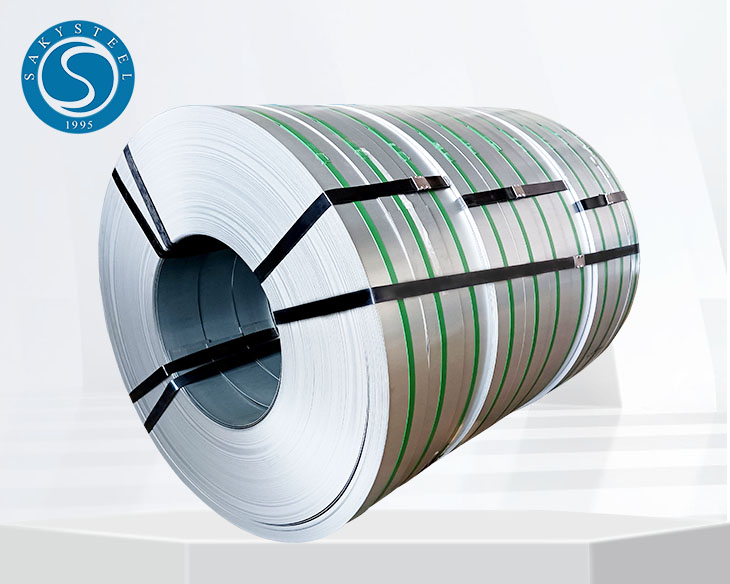

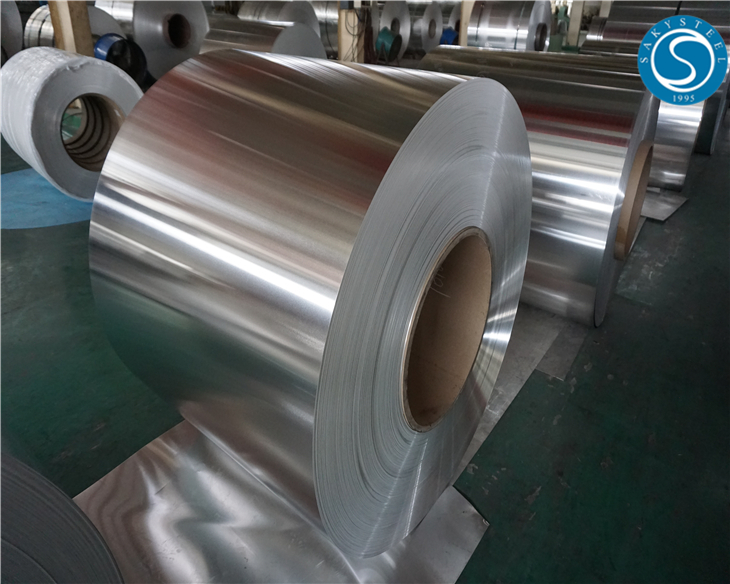

| Fabrication | Malleability, Formability | Easy to Work With, Versatile Applications | Construction, Manufacturing |

| Soldering | Good Electrical Conductivity | Reliable Connections, Reduced Maintenance | Electronics, Automotive |

| Marine Applications | Saltwater Corrosion Resistance | Longevity in Harsh Environments | Shipbuilding, Offshore Platforms |

| Heat Exchangers | High Thermal Conductivity | Efficient Heat Transfer | Energy, HVAC Systems |

Related Products