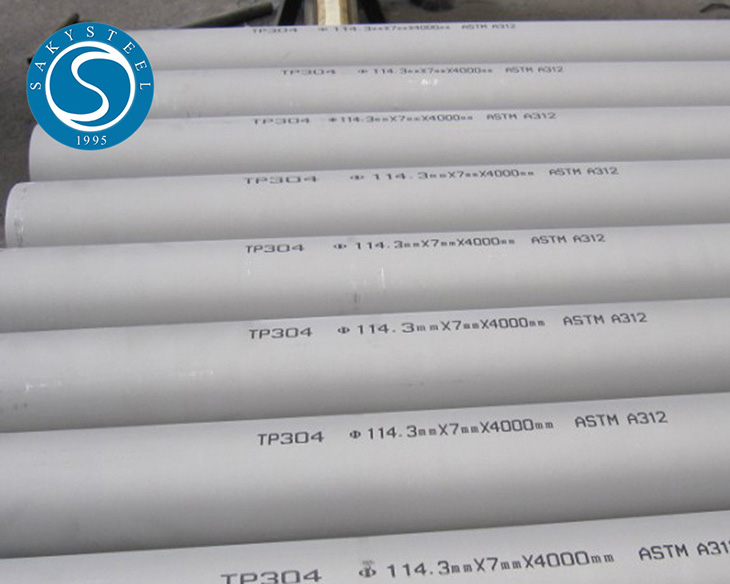

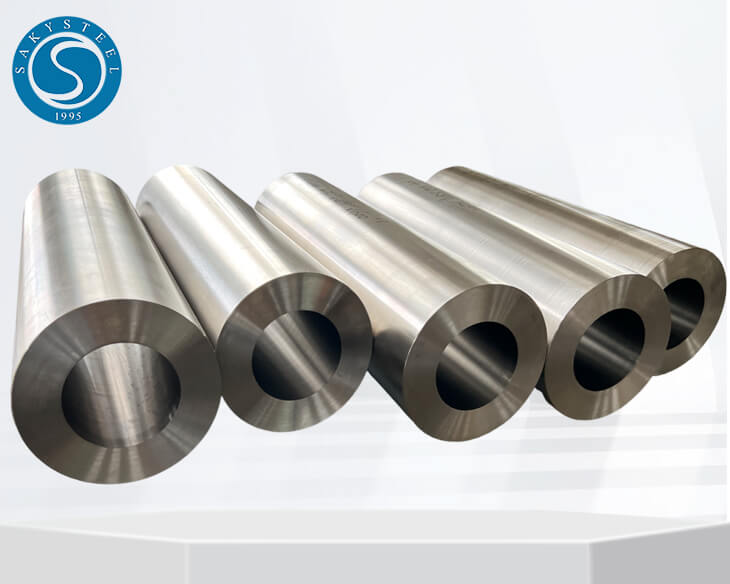

Premium 304 Stainless Steel Tubing for Industrial Applications

When searching for durable and corrosion-resistant materials, I found that 304 stainless steel tubing meets every requirement. Ideal for a wide range of industries, this tubing boasts excellent weldability and formability, making it perfect for various applications like fluid transport and structural supports. I’ve seen firsthand how its resistance to oxidation and aggressive chemicals can enhance product longevity. In my experience, the seamless design of 304 stainless steel tubing not only ensures structural integrity but also reduces maintenance needs. Plus, its polished finish provides an attractive aesthetic, which is a plus in visible installations. For B2B purchasers like myself, the versatility of 304 stainless steel tubing stands out, and its compatibility with multiple environments makes it a go-to choice. So, if you’re aiming for quality and reliability in your projects, this tubing should be on your radar. The long-term benefits and performance guarantee you will be satisfied with your decision.

304 Stainless Steel Tubing Is The Best Sets the Industry Standard

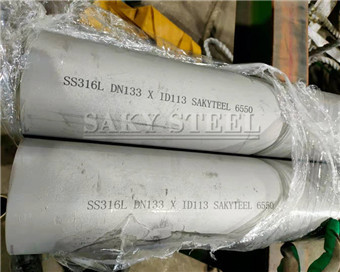

When it comes to industrial applications, the choice of tubing material can significantly impact performance, durability, and cost-efficiency. Among the various options available, 304 stainless steel tubing has emerged as the preferred choice, setting an industry standard that manufacturers around the globe trust. Renowned for its excellent corrosion resistance, 304 stainless steel is ideal for a diverse range of environments, from chemical processing to food and beverage production. Its ability to withstand high temperatures and resist oxidation makes it suitable for both indoor and outdoor applications. In addition to its superior performance characteristics, 304 stainless steel tubing is remarkably versatile. Whether it's for structural applications or fluid transport, its low maintenance requirements and long lifespan translate into reduced operational costs. Furthermore, the ease of fabrication of 304 stainless steel allows for customized solutions tailored to specific project needs. The consistency in quality and availability means that businesses can rely on timely production and delivery, ensuring smoother project timelines and enhanced productivity. For global buyers and procurement specialists, choosing 304 stainless steel tubing is not just a matter of selecting a material; it's an investment in quality and reliability. As industries continue to innovate and pursue sustainability, the demand for high-performance materials like 304 stainless steel tubing will only grow. Partnering with suppliers who prioritize excellence in production and customer service will ensure that you remain at the forefront of your industry, equipped with the best materials for your needs.

304 Stainless Steel Tubing Is The Best Sets the Industry Standard

| Dimension (inches) | OD (Outside Diameter) | ID (Inside Diameter) | Wall Thickness | Weight per Foot | Applications |

|---|---|---|---|---|---|

| 1/4 | 0.540 | 0.364 | 0.088 | 0.20 | Hydraulic Systems |

| 3/8 | 0.675 | 0.487 | 0.094 | 0.26 | Food Processing |

| 1/2 | 0.840 | 0.617 | 0.113 | 0.41 | Marine Applications |

| 3/4 | 1.050 | 0.864 | 0.093 | 0.56 | Chemical Processing |

| 1 | 1.315 | 1.049 | 0.134 | 0.76 | Automotive |

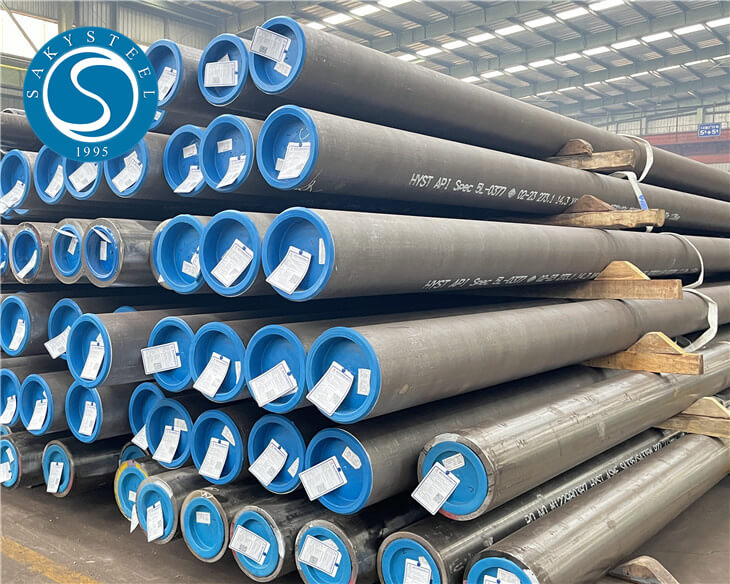

Related Products