304 Stainless Steel Welding Wire: High Quality for Your Projects Needs

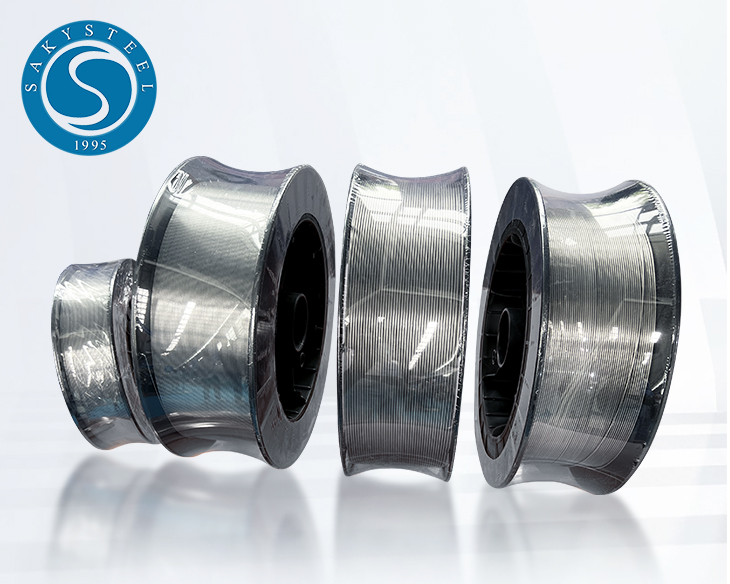

When I set out to find the best welding materials, I knew I had to consider strength and versatility. That's where 304 stainless steel welding wire comes into play. With its excellent resistance to corrosion and high temperatures, this wire is perfect for various fabrication and repair projects. Whether I'm working on food processing equipment, architectural structures, or marine applications, I trust 304 stainless steel to deliver superior performance. What really impressed me is its easy handling and smooth feedability, making my welding tasks quicker and more efficient. Plus, its impressive weldability means I can achieve strong joints without worrying about defects. If you're in the market for reliable welding wire that stands the test of time, look no further. This is the product that fulfills my needs and exceeds my expectations. Don't miss out on the quality that can elevate your projects!

304 stainless steel welding wire Winning in 2025 Your Trusted OEM Partner

As the demand for high-quality stainless steel welding wire continues to rise globally, selecting the right OEM partner becomes crucial for procurement professionals aiming to maintain competitive advantages. By 2025, the market is expected to witness significant shifts, and companies need to align themselves with trusted suppliers who can deliver consistent quality and reliability. With 304 stainless steel welding wire at the forefront, this material is renowned for its excellent corrosion resistance and durability, making it ideal for a variety of applications, from construction to automotive sectors. Choosing an OEM partner who understands the nuances of the global market is essential. They should possess robust manufacturing capabilities, stringent quality control processes, and a commitment to customer satisfaction. A dedicated partner can provide tailored solutions that meet specific project requirements, ensuring that products not only comply with international standards but also perform reliably under various conditions. As we head towards 2025, aligning with an experienced supplier will not only enhance your supply chain resilience but also drive innovation in your welding projects. In conclusion, as procurement strategies evolve, securing a trustworthy OEM partner for 304 stainless steel welding wire should be a priority for businesses aiming to thrive in the future market landscape. By focusing on collaboration and quality, companies can better navigate the complexities of global sourcing and remain at the cutting edge of their industries. The right partnership can pave the way for sustained growth and success, reinforcing your position in an increasingly competitive marketplace.

304 Stainless Steel Welding Wire - Winning in 2025 Your Trusted OEM Partner

| Parameter | Details |

|---|---|

| Material Type | 304 Stainless Steel |

| Wire Diameter | 0.8 mm - 2.0 mm |

| Welding Process | MIG, TIG |

| Applications | Food Industry, Chemical Tanks, Automotive |

| Tensile Strength | 520 MPa |

| Yield Strength | 210 MPa |

| Elongation | 40% |

| Common Standards | AWS ER308L, ISO 14343-A |

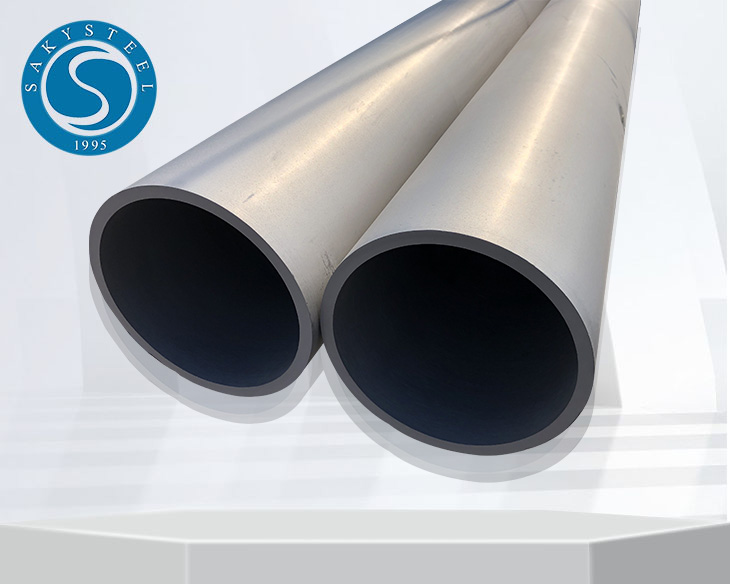

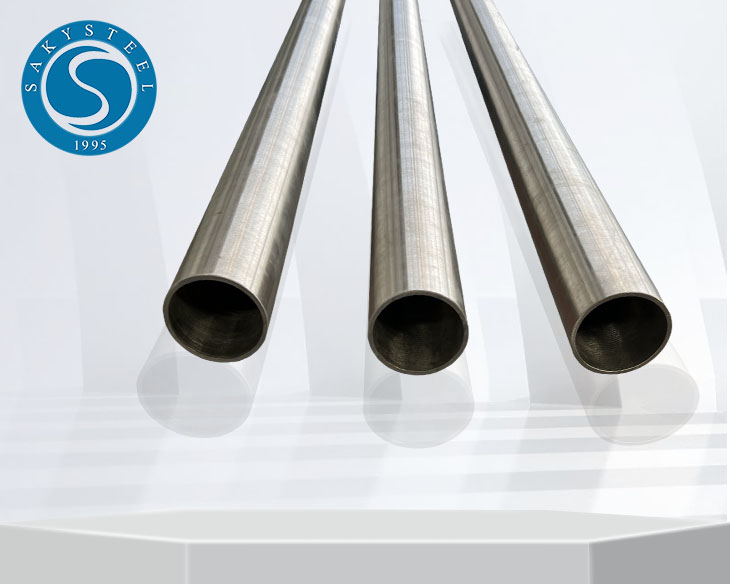

Related Products