Find the Best 309 Mig Wire for Your Welding Projects Today!

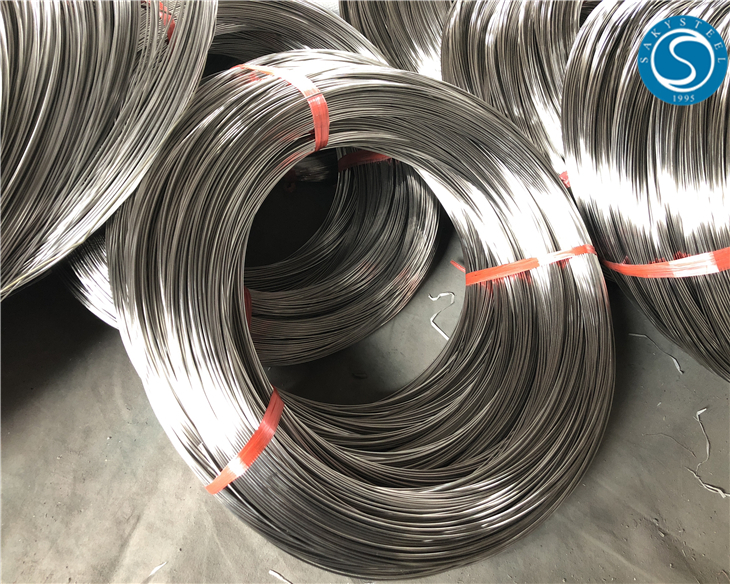

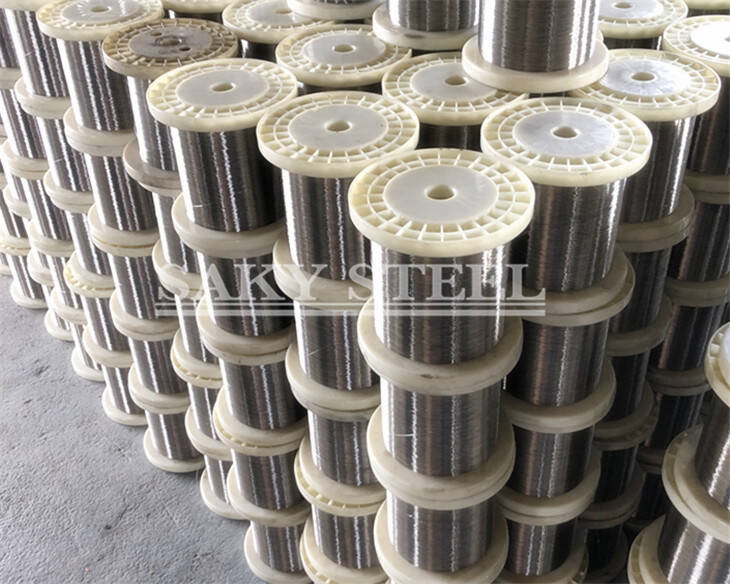

When it comes to reliable welding solutions, I often find myself reaching for 309 Mig Wire. This sturdy wire is perfect for stainless steel applications, providing superior corrosion resistance. If you're in the market for high-quality welding materials, this wire delivers excellent arc stability and a smooth feed. As a seasoned welder, I’ve seen firsthand how 309 Mig Wire enhances the overall integrity of my projects. Whether I’m working on metal fabrication or maintenance, I always trust this wire to give me consistent performance and clean welds. If you're considering upgrading your supplies, I highly recommend checking out 309 Mig Wire. It's a game changer for anyone serious about their welding needs. And with reliability like this, your projects will surely stand the test of time. Don't miss out on the chance to elevate your work with this essential welding material!

309 Mig Wire Dominates Global Reach

The global market for welding consumables is ever-evolving, with 309 MIG wire emerging as a leading choice for manufacturers and fabricators worldwide. This alloy steel wire offers exceptional corrosion resistance and high strength, making it the preferred option for a variety of applications, including automotive, construction, and shipbuilding. As businesses are continuously seeking to enhance their production processes, the versatility and performance of 309 MIG wire stand out, driving its dominance in the market. Purchasing 309 MIG wire not only ensures superior weld quality but also contributes to cost efficiency through reduced rework and material waste. Its ability to perform in demanding environments positions it as an essential material for industries that require reliability and durability. For global buyers looking to streamline their operations and enhance product offerings, the procurement of high-quality 309 MIG wire represents a strategic decision that aligns with contemporary manufacturing standards. In a competitive landscape, companies that prioritize sourcing premium welding materials, such as 309 MIG wire, are poised to increase their manufacturing capabilities and maintain a strong market presence. As the industry continues to innovate, embracing advanced materials will be key to staying ahead. The future of welding technologies is bright, and investing in 309 MIG wire now will ensure that businesses remain at the forefront of their respective fields.

309 Mig Wire Dominates Global Reach

| Region | Market Share (%) | Annual Growth Rate (%) | Key Drivers |

|---|---|---|---|

| North America | 35 | 5.5 | Rising automotive demand |

| Europe | 30 | 4.0 | Technological advancements |

| Asia-Pacific | 25 | 6.0 | Infrastructure development |

| Latin America | 5 | 3.5 | Investment in manufacturing |

| Middle East & Africa | 5 | 2.8 | Rising oil & gas sector |

Related Products