Quality 310s Stainless Steel Pipe for Durable Applications - Fast Delivery

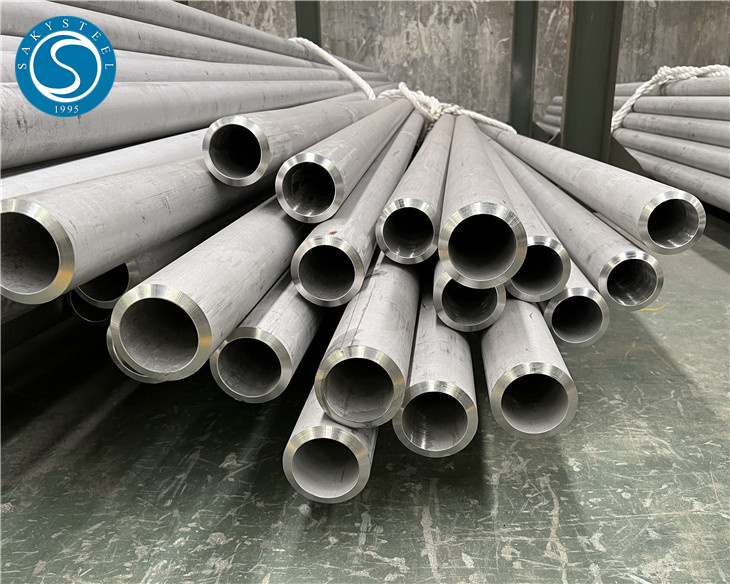

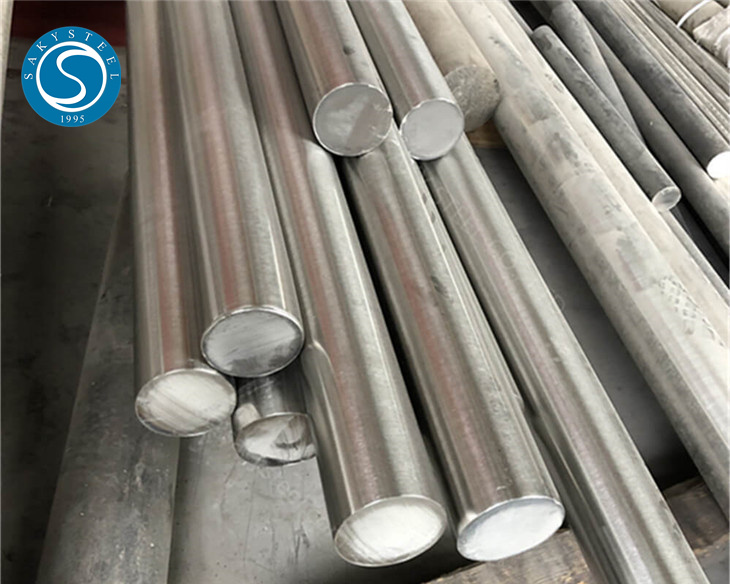

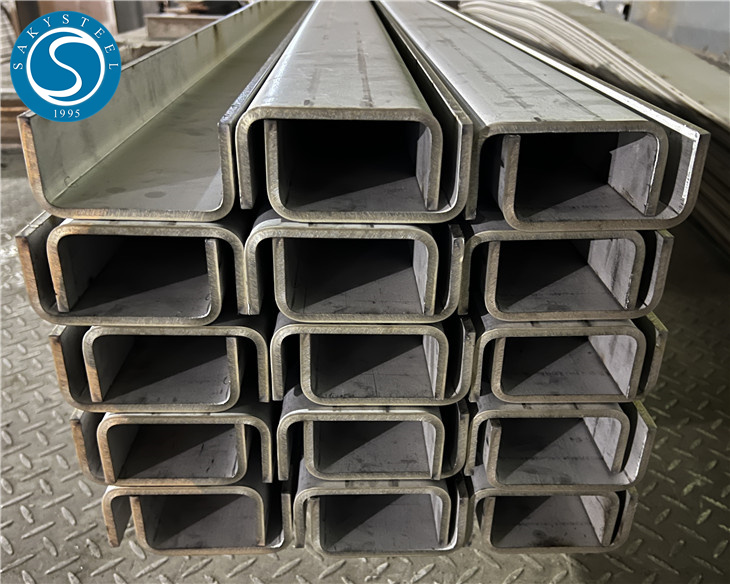

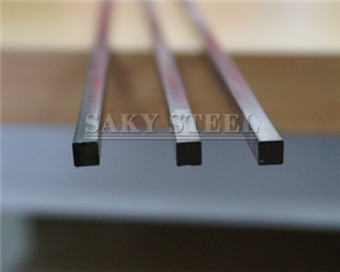

When it comes to strength and durability, I find 310s Stainless Steel Pipe to be unmatched in the industry. Perfect for high-temperature applications, it's designed to withstand extreme environments without losing structural integrity. I often recommend this pipe for chemical processing and oil refining projects because of its excellent resistance to oxidation and corrosion. What sets 310s apart is not just its composition but how it adapts to various applications, making it a favorite among my clients. Also, it’s easy to weld and fabricate, saving time and money on setup. Whether you're sourcing for a large-scale project or a smaller application, I ensure my stock meets the highest industry standards. Plus, I offer competitive pricing and fast delivery, making your purchasing process a breeze. Let's make your next project a success with reliable 310s Stainless Steel Pipe!

310s Stainless Steel Pipe Application Where Innovation Meets 2025

In the ever-evolving landscape of industrial materials, the versatility of 310S stainless steel pipes stands out, particularly as we look towards the innovative advancements expected by 2025. Known for its exceptional corrosion resistance and high-temperature strength, 310S is increasingly being utilized in various applications, from petrochemical facilities to aerospace components. This stainless steel alloy's ability to withstand harsh environments makes it an ideal choice for global procurement efforts focused on durability and reliability. As industries strive for greater efficiency and sustainability, the demand for high-performance materials like 310S stainless steel pipes is set to grow. Innovations in manufacturing techniques, such as improved welding and fabrication processes, are enhancing the usability of these pipes in complex systems. Furthermore, as global supply chains seek to minimize disruptions, the availability of 310S pipes from trusted sources is becoming essential for manufacturers aiming to meet their production requirements while maintaining quality standards. Looking ahead, embracing the properties of 310S stainless steel pipes not only aligns with current industry standards but also positions procurement strategies for future success. By focusing on innovative applications and reliable sourcing, businesses can ensure they are equipped to face the challenges of tomorrow, making informed decisions that drive progress and sustainability in their operations.

310s Stainless Steel Pipe Application Where Innovation Meets 2025

| Application Area | Temperature Range (°C) | Corrosion Resistance | Tensile Strength (MPa) | Yield Strength (MPa) | Ductility (%) |

|---|---|---|---|---|---|

| Chemical Processing | -200 to 800 | Excellent | 750 | 310 | 40 |

| Oil and Gas Industry | -150 to 700 | Good | 720 | 305 | 35 |

| Aerospace | -200 to 650 | Excellent | 780 | 320 | 42 |

| Marine Applications | -100 to 600 | Very Good | 760 | 315 | 38 |

| Power Generation | -50 to 800 | Good | 740 | 310 | 37 |

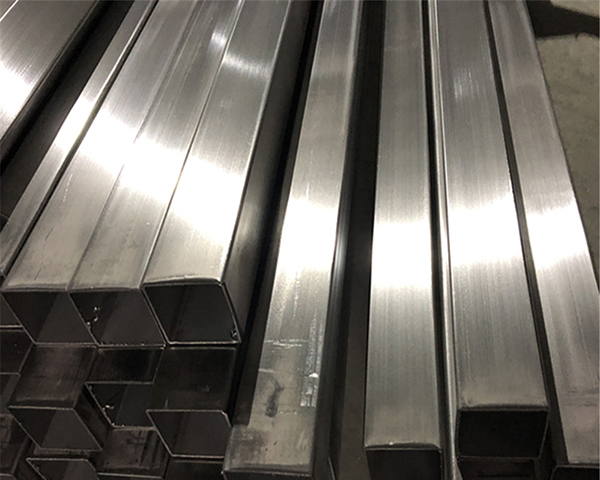

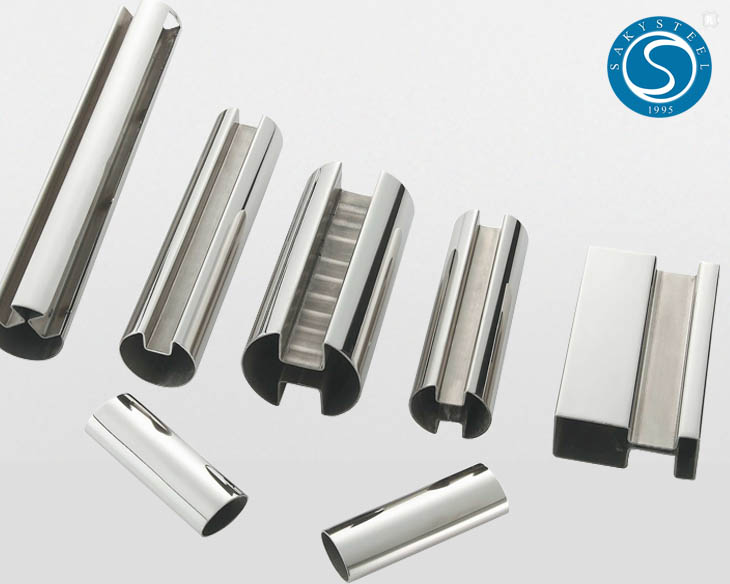

Related Products