A2 Tool Steel Hardness: Key Specs for Optimal Performance & Durability

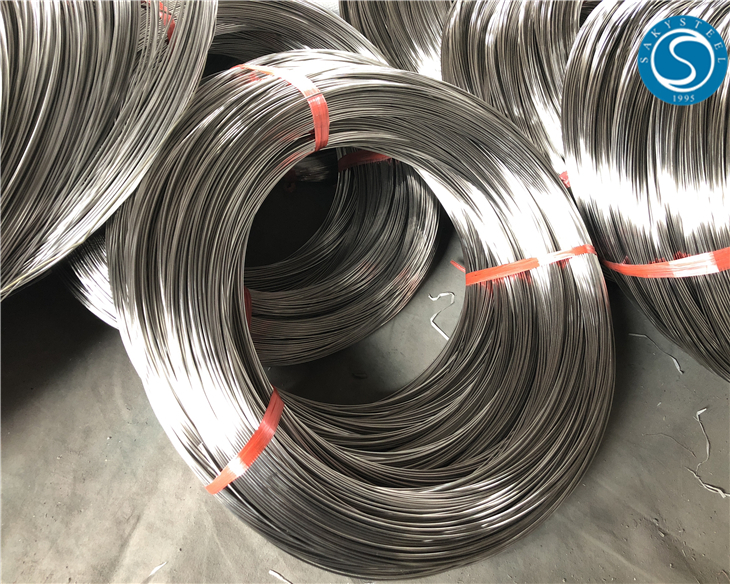

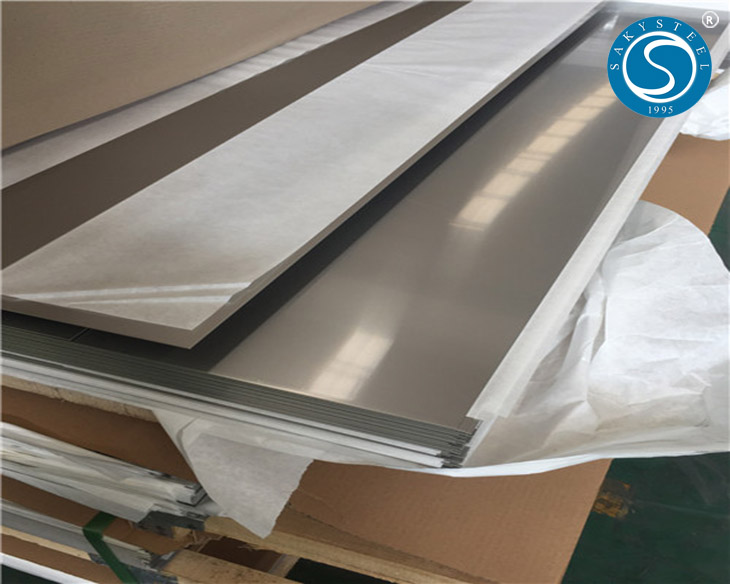

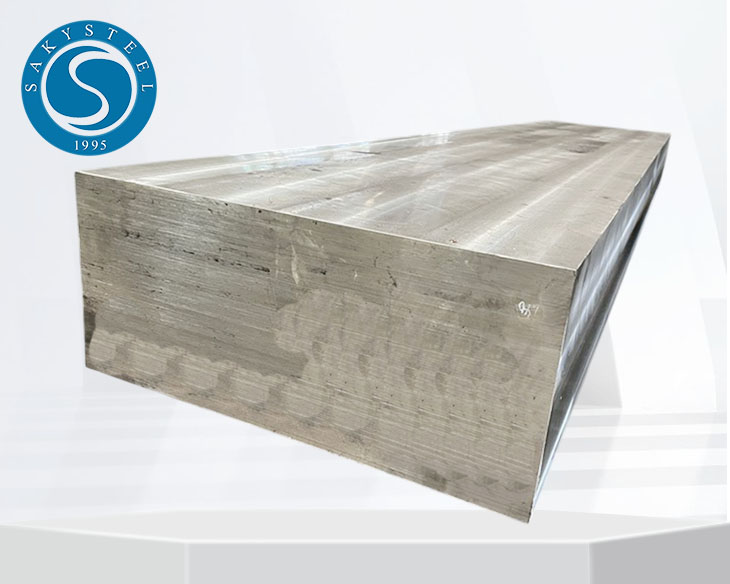

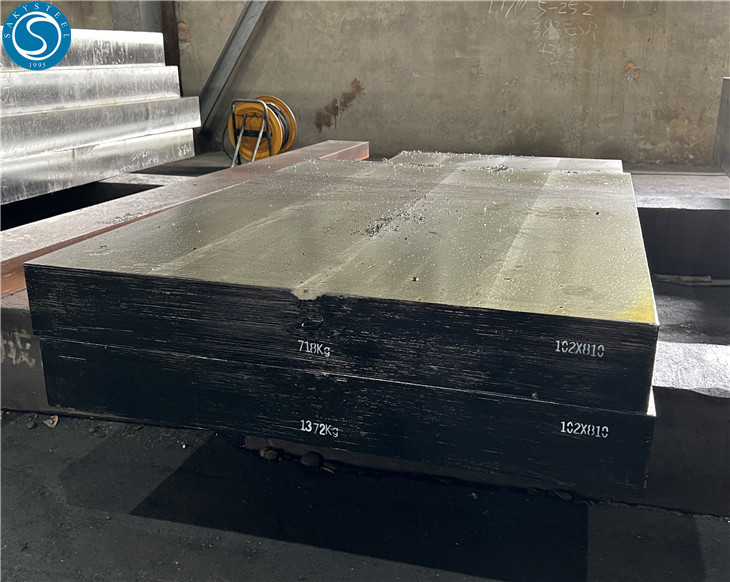

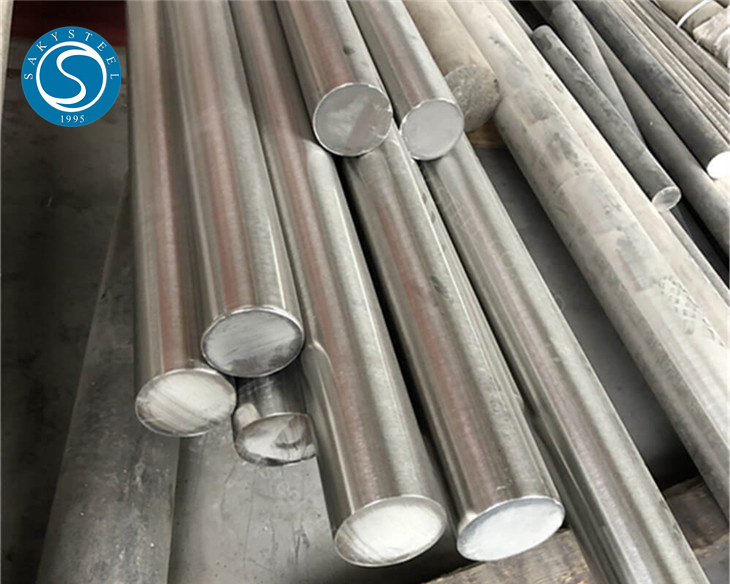

When you're in need of high-quality A2 tool steel hardness, I understand the weight of finding the right supplier. This steel offers remarkable toughness and excellent wear resistance, perfect for forming tools and dies. It’s ideal for applications where dimensional stability is a must, and its hardness ensures precision and durability. With A2 tool steel, I can appreciate its ability to maintain an edge even under pressure. Buyers often appreciate the balance between cost-effectiveness and top-tier performance. Whether you're creating intricate molds or rugged parts, A2 is a go-to that won't disappoint. By choosing us, you're not just getting steel; you're getting a partner who values your needs. We're committed to helping you make the best materials choice for your projects. If hardness, strength, and reliability are what you're after, then let's connect and discuss how our A2 tool steel can work for you.

A2 Tool Steel Hardness Your End-to-End Solution Service Backed by Expertise

When it comes to sourcing A2 tool steel, understanding its hardness and overall performance is crucial for manufacturers and engineers alike. A2 tool steel offers a remarkable combination of toughness, wear resistance, and excellent edge retention, making it a popular choice for various applications such as dies, punches, and machining tools. By choosing A2, you are ensuring that your tools can withstand the rigors of heavy-duty use, promoting longevity and reliability in your operations. Our comprehensive service is designed to support you throughout the purchasing process. From selecting the right steel for your application to timely delivery, our team of experts is here to guide you every step of the way. We prioritize quality and consistency, ensuring that every batch of A2 tool steel meets industry standards and specifications. Our commitment to customer satisfaction means we are always available to provide insights and answer any questions you may have, making your sourcing experience seamless and efficient. In a global marketplace, the right partnerships can significantly impact your production efficiency and product quality. By leveraging our end-to-end service and expertise in A2 tool steel, you can confidently fulfill your project requirements. With a keen focus on innovation and technology, we aim to empower manufacturers around the world, helping them achieve their goals with the best materials and services available.

A2 Tool Steel Hardness - Your End-to-End Solution Service Backed by Expertise

| Characteristic | Value | Unit | Remarks |

|---|---|---|---|

| Hardness (Rockwell) | 60-62 | HRC | Typical range for A2 tool steel |

| Tensile Strength | 1,200 | MPa | High tensile strength for tough applications |

| Yield Strength | 900 | MPa | Sufficient for various tooling applications |

| Impact Toughness | 40 | J | Good impact resistance |

| Elongation | 12 | % | Indicates ductility of the material |

Related Products