Er2209 Filler Wire: Best Prices for Quality Welding Supplies Online

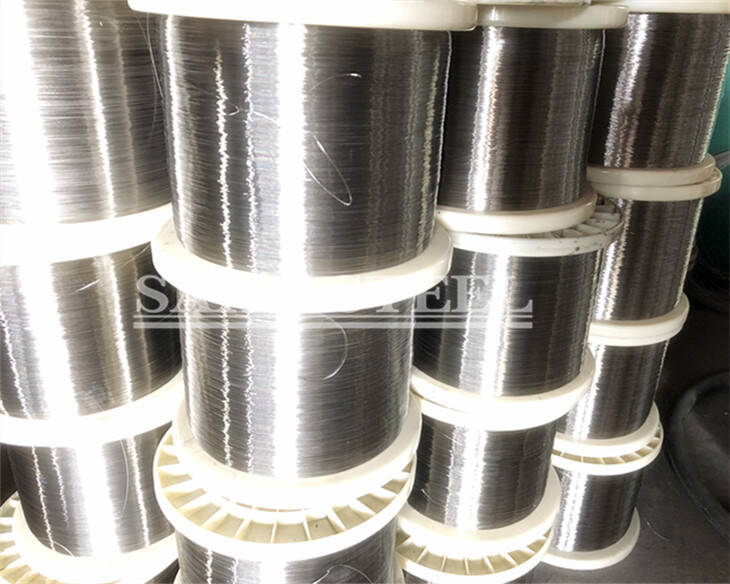

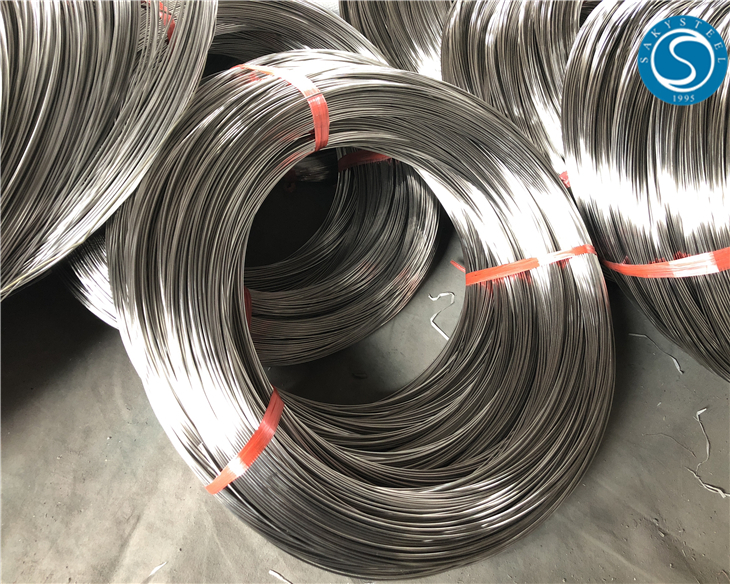

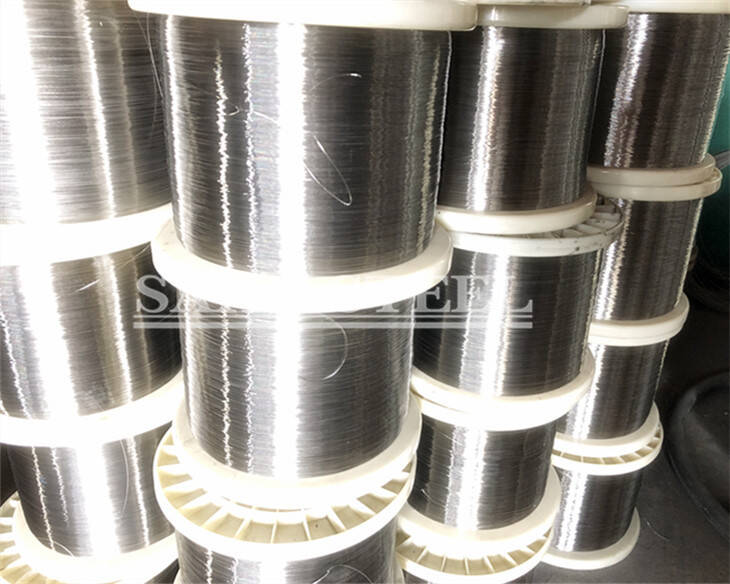

When it comes to welding projects, I understand the importance of using high-quality materials, and that's why I recommend the ER2209 filler wire. This product is designed specifically for welding duplex stainless steels, ensuring strong and durable joints that can withstand harsh environments. I've seen how well it performs in various applications, from construction to shipbuilding, making it a top choice for professionals. With its excellent corrosion resistance and high strength, the ER2209 filler wire meets the demanding needs of skilled tradespeople. I also appreciate its versatility, as it works well with both TIG and MIG welding processes, allowing for greater flexibility on the job. If you're a B2B purchaser looking for reliable welding solutions, this filler wire could just be what you need to enhance your project's quality and efficiency. Trust me, you won’t be disappointed with the results it delivers!

Er2209 Filler Wire Market Leader Where Service Meets Innovation

In the dynamic landscape of the filler wire market, the demand for reliable quality and innovative solutions is ever-increasing. The ER2209 filler wire stands out, combining exceptional performance with enhanced corrosion resistance, making it a preferred choice for various industries, from construction to manufacturing. This product not only meets the stringent requirements of modern welding applications but also addresses the growing need for sustainability by promoting longer-lasting solutions. As a leader in the industry, we understand that the key to success lies in delivering unparalleled service alongside our top-notch products. We are committed to ensuring that our clients receive not just the materials they need, but also expert support and guidance throughout their procurement process. Our dedicated team works tirelessly to identify innovative approaches that help businesses optimize their operations, reduce costs, and improve overall efficiency. With a focus on both innovation and service, we are driven to support our global partners in navigating the complexities of the filler wire market. We believe that by fostering strong relationships and being attuned to the needs of our clients, we can cultivate an environment where businesses thrive, and together, we can address the challenges facing the industry today. Embrace the future of welding materials with a partner who prioritizes your success.

Er2209 Filler Wire Market Leader Where Service Meets Innovation

| Application | Material Type | Welding Technique | Diameter (mm) | Strength (MPa) | Features |

|---|---|---|---|---|---|

| Marine Construction | Stainless Steel | MIG | 1.2 | 580 | Corrosion Resistant |

| Automotive | Carbon Steel | TIG | 1.0 | 600 | High Durability |

| Construction | Alloy Steel | Flux-Cored | 1.6 | 500 | High Impact Resistance |

Related Products