Er309l Mig Wire: Top Choice for Quality Welding and Performance

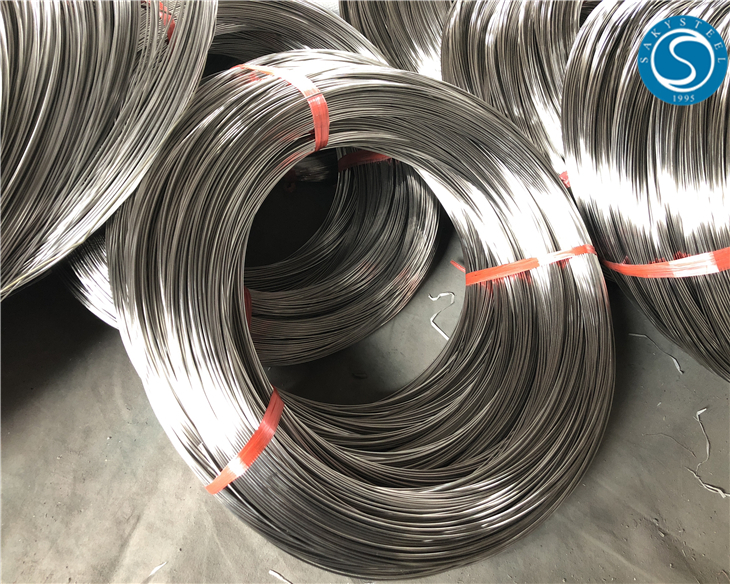

When I'm on the hunt for quality materials, Er309l Mig Wire stands out for its reliability and performance. This versatile wire is specifically designed for welding stainless steel, and I find it perfect for projects requiring a strong, durable joint. With its excellent wetting characteristics and smooth arc stability, it just makes my life easier and boosts productivity. I appreciate how Er309l is compatible with various shielding gases, which gives me flexibility. Plus, using this wire means better resistance to corrosion and oxidation—essential for long-lasting results. Whether you're working in shipbuilding, construction, or another industrial application, I can confidently say that this wire meets the high standards we all look for. Choosing Er309l Mig Wire is choosing durability and quality for your welding needs. Don't compromise; invest in the best for your business.

Er309l Mig Wire Products Industry Giant

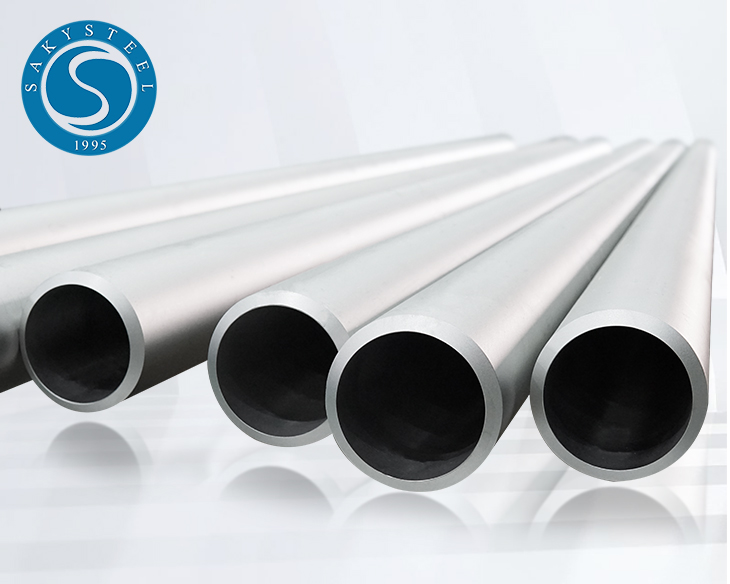

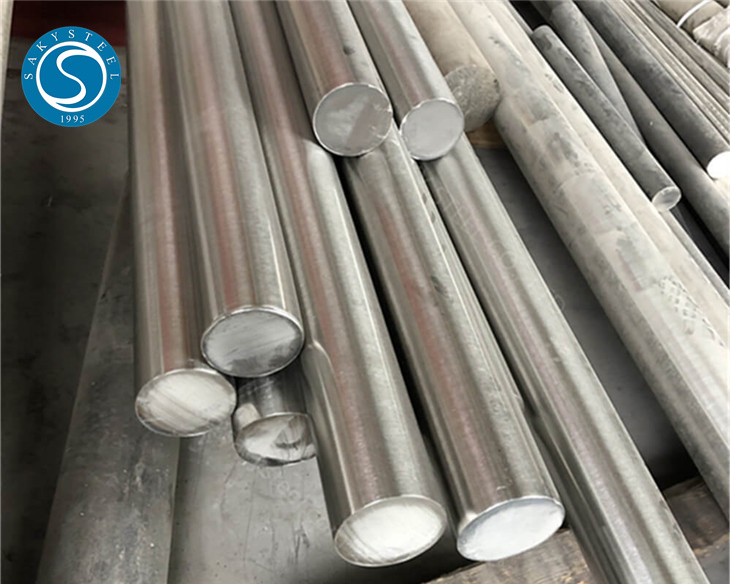

In the ever-evolving landscape of welding technology, ER309L MIG wire stands out as a superior choice for various industries due to its exceptional corrosion resistance and high-temperature performance. This versatile filler metal is ideal for welding stainless steels, particularly in environments where oxidation and corrosion are prevalent. Its chemical composition, which includes a balanced mix of chromium and nickel, ensures that welds maintain their strength and durability, even in demanding applications. Global buyers looking for reliable MIG wire solutions can benefit from understanding the significance of sourcing high-quality ER309L products. The right MIG wire not only improves weld quality but also enhances productivity and reduces downtime. This is especially important for industries such as construction, automotive, and shipbuilding, where the integrity of welds is critical. By partnering with a reputable supplier, purchasing agents can secure materials that meet rigorous standards, ultimately ensuring that their projects stand the test of time. Moreover, as industries embrace innovation and sustainability, the demand for efficient and effective welding solutions continues to rise. ER309L MIG wire aligns perfectly with these trends, offering a combination of performance and reliability. Buyers across the globe are encouraged to explore options that provide not just quality materials but also technical support and guidance to optimize their welding processes. This strategic approach will empower businesses to achieve their operational goals while maintaining safety and environmental standards.

Er309l Mig Wire Products Industry Giant

| Product Type | Material Composition | Diameter (mm) | Length (m) | Application Area |

|---|---|---|---|---|

| ER309L | 24% Cr, 13% Ni | 0.8 | 15 | Austenitic Stainless Steel Welding |

| ER309L | 24% Cr, 12% Ni | 1.0 | 20 | High-Temperature Applications |

| ER309L | 22% Cr, 11% Ni | 1.2 | 30 | Chemical Processing |

| ER309L | 23% Cr, 10% Ni | 1.6 | 25 | Marine Applications |

Related Products