Top Quality Stainless Steel Flange for Durable Industrial Solutions

When I think about reliable solutions for piping systems, Stainless Steel Flange comes to mind immediately. As a key component for secure connections, these flanges provide superior strength and corrosion resistance that enhance the durability of any project. I understand that quality is crucial when selecting the right products, so I always recommend choosing flanges that meet industry standards for safety and performance. I’ve seen firsthand how investing in high-quality stainless steel flanges can save both time and money in the long run, reducing the need for replacements or repairs. Whether you’re working on a large-scale industrial installation or a smaller project, these flanges are designed for easy assembly and ensure a tight seal every time. If you’re searching for reliable suppliers with excellent customer service, I can vouch for companies that prioritize their clients’ needs. It’s not just about the product; it’s about a partnership that drives success. Let's connect and get you those flanges!

Stainless Steel Flange Products Industry Leaders

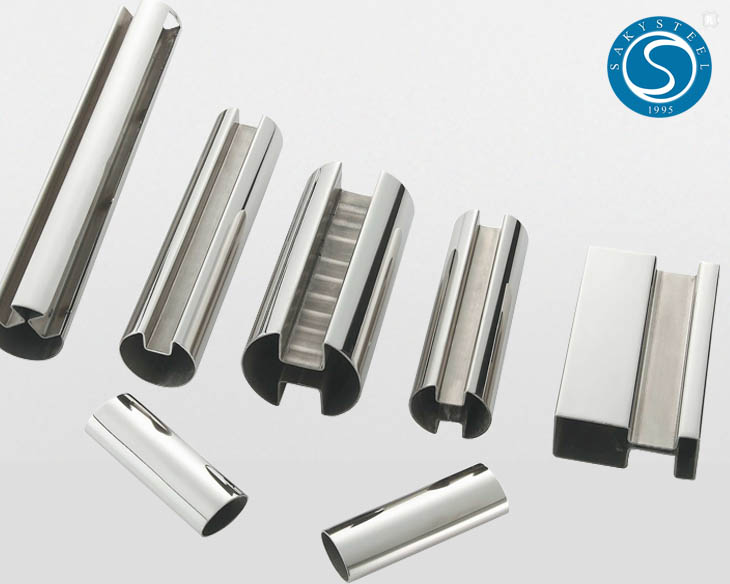

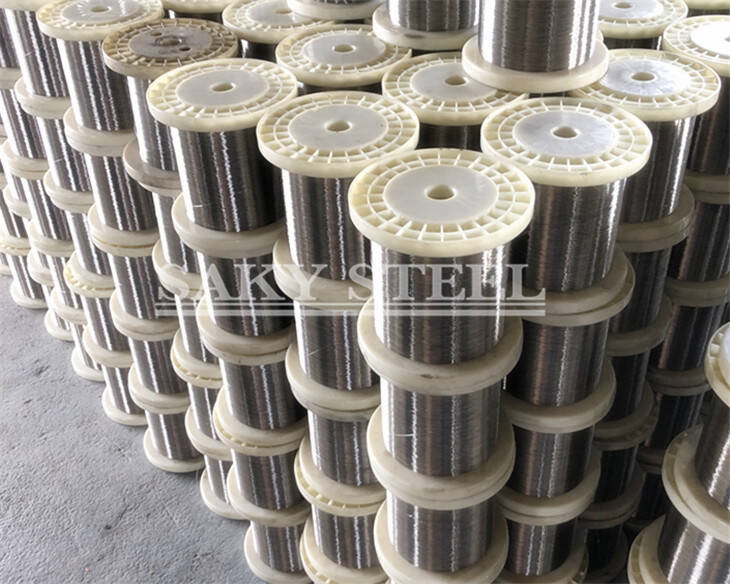

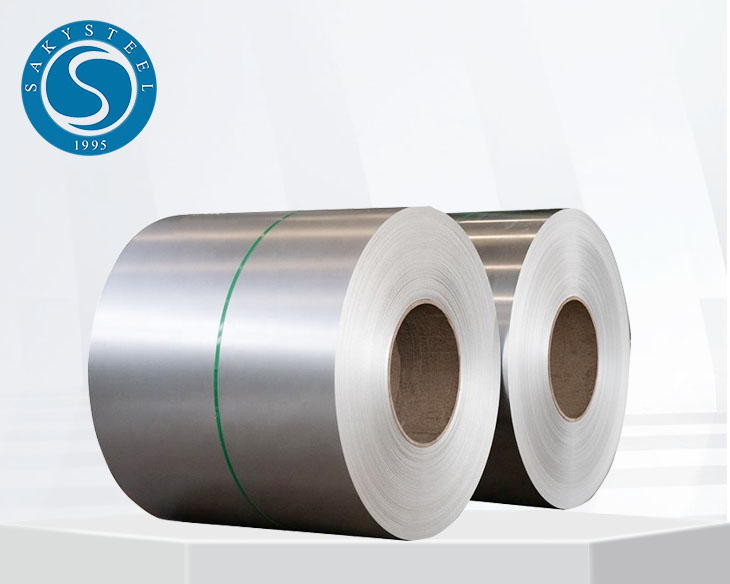

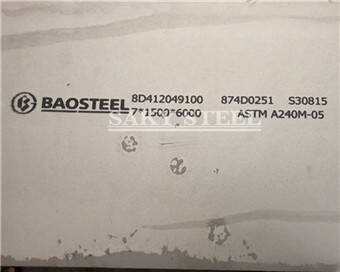

In the competitive landscape of the stainless steel flange products industry, standing out as a leader requires not only a commitment to quality but also an adaptability to market demands. The industry is driven by a diverse range of sectors including construction, automotive, and oil and gas, which all rely heavily on robust and reliable flange solutions. As procurement professionals explore their options, understanding the importance of quality assurance and material expertise becomes vital. Premium stainless steel flanges offer enhanced durability and corrosion resistance, ensuring longevity and performance even in the most challenging environments. Innovative manufacturing processes play a pivotal role in delivering superior flange products that meet global standards. Advanced techniques such as seamless forging and precision machining enhance the structural integrity of flanges, reducing the risk of leaks and failures. Additionally, a wide array of options, including different sizes and pressure ratings, allows for tailored solutions that fit specific project requirements. Collaborating with industry leaders ensures access to cutting-edge technology and expertise, facilitating successful project completion while minimizing downtime and risks associated with subpar materials. Sustainability is another critical factor influencing global procurement decisions. Industry leaders are increasingly adopting eco-friendly practices, from sourcing raw materials to energy-efficient production methods. Procurement professionals can enhance their supply chains by choosing partners committed to sustainable operations, ultimately contributing to their own environmental goals. As the market evolves, staying informed about the latest advancements and maintaining strong partnerships will be essential for procurement success in the stainless steel flange market.

Stainless Steel Flange Products Industry Leaders

| Company Type | Product Type | Material Standard | Applications | Country of Origin |

|---|---|---|---|---|

| Manufacturer | Weld Neck Flange | ASTM A182 | Oil & Gas | USA |

| Supplier | Blind Flange | ANSI B16.5 | Chemical Processing | Germany |

| Distributor | Socket Weld Flange | ASME SA182 | Power Generation | China |

| Manufacturer | Lap Joint Flange | BS 4504 | Water Treatment | Italy |

| Supplier | Threaded Flange | DIN 2573 | Marine Engineering | South Korea |

Related Products