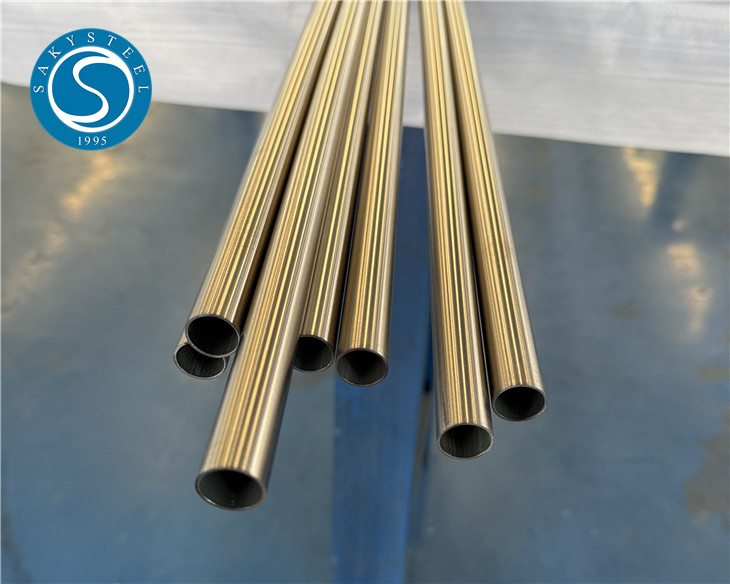

Urea-Grade Austenitic Seamless Stainless Steel Tubes

Short Description:

Urea grade austenitic seamless stainless steel tubes with low Si & high corrosion resistance, ideal for urea synthesis and fertilizer plants.

This type of seamless stainless steel pipe is mainly applied in critical equipment and core systems of ammonia synthesis and urea production plants. The raw materials are refined through electroslag remelting (ESR), ensuring high purity and structural uniformity. During manufacturing, in addition to strict cleanliness control, particular attention is given to precise heat treatment management to achieve optimal metallurgical performance.

At present, such urea-grade stainless steel products in China still depend largely on imports. Our company independently manufactures urea-grade ultra-pure stainless stels, primarily including ultra-pure 316Lmod and S31050. Both grades belong to fully austenitic, ultra-high-purity stainless steels, specifically developed to overcome the selective corrosion problems caused by ferrite phases in ammonia and carbamate environments during urea synthesis.

Throughout the production process, all products are manufactured in strict compliance with relevant standards. After passing the Hughes test, they demonstrate outstanding corrosion resistance performance. In addition to urea and ammonia applications, these materials are also widely used in the hydrogen energy industry due to their excellent corrosion resistance and material stability.

| Specifications of Urea grade stainless steel seamless tube: |

| Specifications | ASTM A269,JIS3459 |

| Grade | 316,S31050,316LVM,316Lmod |

| Type | Seamless pipe |

| Specification range | 3.175-325×0.5-20MM |

| Wall Thickness | 0.5 mm – 20 mm (custom thickness on request) |

| Outside diameter | 3.175-325mm |

| Length | Up to 6000 mm (custom lengths available) |

| Surface | Bright |

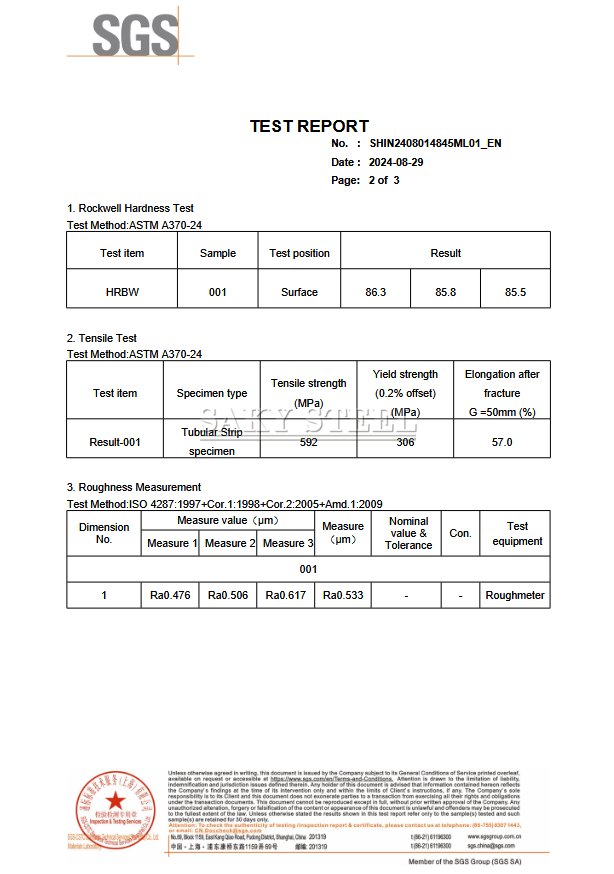

| Urea grade stainless steel seamless tube Roughness Test : |

To ensure superior surface quality for high-purity and corrosion-resistant applications, strict surface roughness inspections are carried out during production. High-precision surface roughness measuring instruments are used to evaluate both inner and outer surfaces, with particular emphasis on the inner surface condition. Multiple measurement points are recorded to guarantee consistent and uniform surface quality. Through controlled manufacturing processes and rigorous inspection procedures, the tubes achieve a smooth, defect-free surface, effectively reducing media retention and corrosion risks, and fully meeting the requirements of urea plants and high-purity fluid transmission systems.

| Support for third-party sample testing : |

|

|

| Eddy Current Test: |

To ensure the highest level of product reliability and structural integrity, all seamless stainless steel tubes undergo eddy current testing during production. This non-destructive inspection method is used to detect surface and near-surface defects, including cracks, pinholes, and other imperfections that may affect performance. By strictly following standardized testing procedures and applying advanced inspection equipment, we ensure consistent quality and dependable performance of our tubes in critical applications such as urea, ammonia, and high-purity process systems.

| Key Features of Urea grade austenitic stainless steel tube : |

-

Low silicon content to prevent corrosion in urea service

-

Excellent resistance to ammonium carbamate corrosion

-

Seamless structure ensures high pressure resistance

-

High purity austenitic stainless steel microstructure

-

Suitable for high temperature and high pressure urea environments

| Urea grade stainless steel seamless tube Applications: |

Urea-grade austenitic seamless stainless steel tubes are widely used in critical and highly corrosive service environments where superior purity and corrosion resistance are required. Typical applications include:

-

Urea synthesis and ammonia production units

-

High-pressure equipment in fertilizer and chemical processing plants

-

Carbamate condensers, strippers, and heat exchangers

-

High-purity gas and fluid piping systems

-

Hydrogen energy and related clean energy facilities

These tubes provide reliable performance under high temperature, high pressure, and aggressive media conditions, ensuring long-term operational safety and stability.

| FAQ : |

Q1: What is urea-grade austenitic stainless steel tube?

Urea-grade austenitic stainless steel tube is a high-purity seamless tube specifically developed for urea and ammonia service. It features extremely low impurity and ferrite content, providing excellent resistance to selective corrosion in carbamate and ammonia environments.

Q2: Why is low ferrite content important for urea applications?

Ferrite phases are highly susceptible to selective corrosion in ammonia and urea synthesis environments. Urea-grade stainless steels are designed with a fully austenitic structure to eliminate ferrite-related corrosion risks and ensure long-term service reliability.

Q3: What grades are commonly used for urea-grade seamless tubes?

Common urea-grade stainless steel grades include ultra-pure 316Lmod and S31050. These grades are specifically engineered for high corrosion resistance and stability under high-temperature and high-pressure urea service conditions.

Q4: What manufacturing processes are applied to ensure product quality?

The raw materials are refined through electroslag remelting (ESR), followed by strict control of cleanliness and heat treatment processes. Each tube undergoes comprehensive inspection, including eddy current testing and corrosion testing such as the Hughes test.

| Why Choose SAKYSTEEL : |

Reliable Quality – Our stainless steel bars, pipes, coils, and flanges are manufactured to meet international standards such as ASTM, AISI, EN, and JIS.

Strict Inspection – Every product undergoes ultrasonic testing, chemical analysis, and dimensional control to ensure high performance and traceability.

Strong Stock & Fast Delivery – We maintain regular inventory of key products to support urgent orders and global shipping.

Customized Solutions – From heat treatment to surface finish, SAKYSTEEL offers tailor-made options to match your exact requirements.

Professional Team – With years of export experience, our sales and technical support team ensures smooth communication, quick quotations, and full documentation service.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,