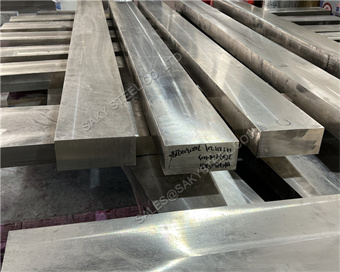

303 Stainless Steel Flat Bar: Durable, Cost-Effective Solutions for Projects

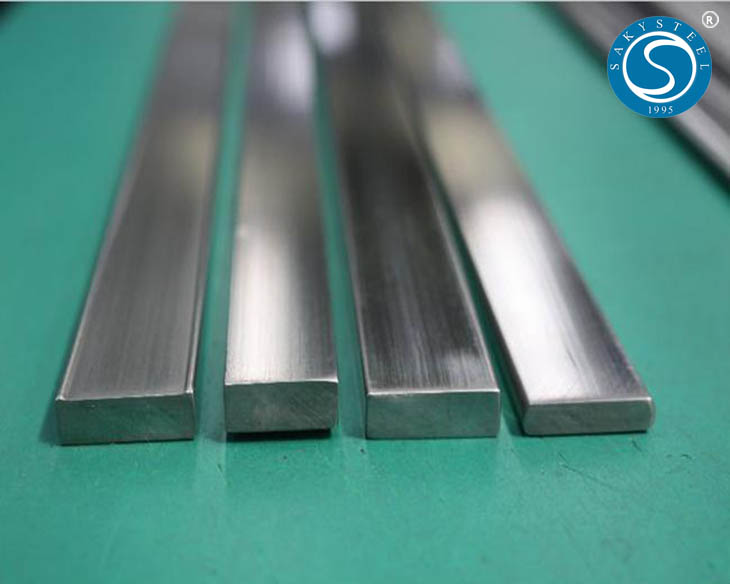

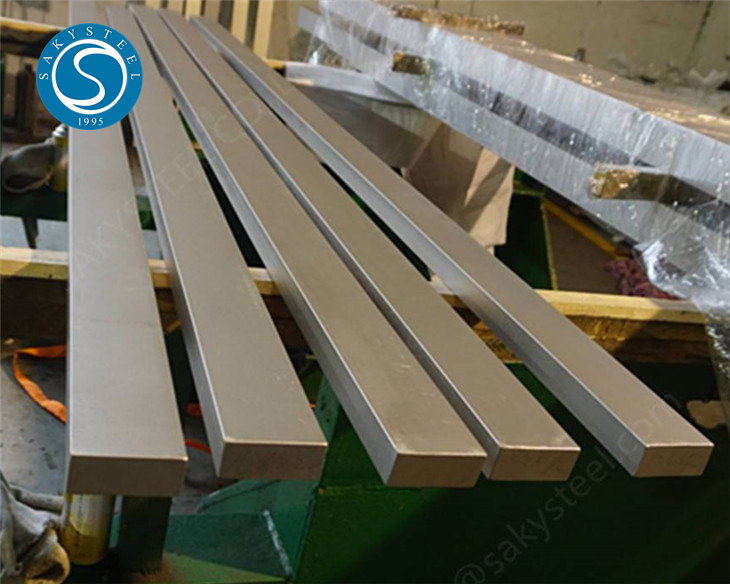

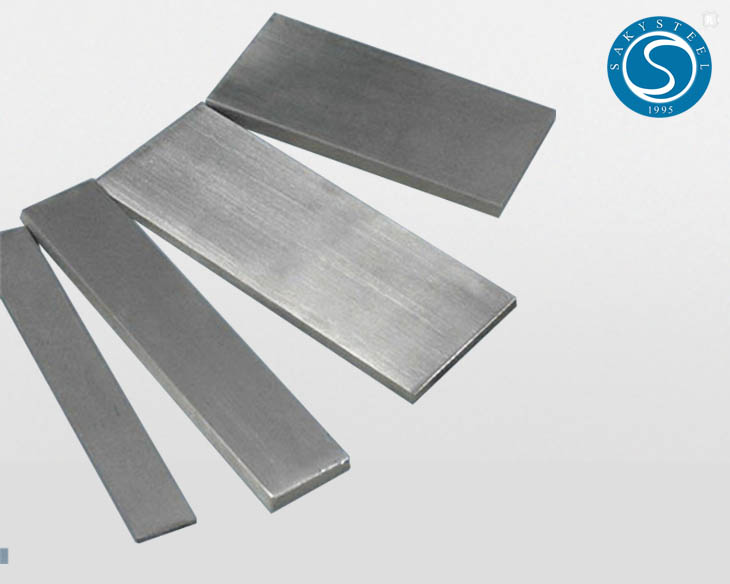

When it comes to sourcing high-quality 303 stainless steel flat bars, I've found that they stand out for their exceptional machinability and corrosion resistance. This makes them perfect for a range of applications, whether it's in automotive parts or precision machinery components. What’s great about these flat bars is their availability in various sizes, making it easy to find the right fit for any project. Purchasing 303 stainless steel flat bars means investing in durability and reliability. I've noticed that clients often appreciate the cost-effectiveness of these materials, as they reduce maintenance needs in the long run. With our commitment to quality, you can be sure you're getting a product that meets industry standards. Plus, we offer flexible delivery options to ensure you get what you need when you need it. Trust me, choosing 303 stainless steel flat bars from us will enhance your projects significantly.

303 Stainless Steel Flat Bar in 2025 Your End-to-End Solution

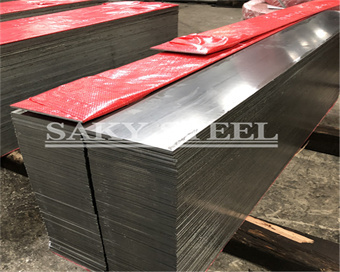

As industries continue to evolve, the demand for high-quality materials like 303 stainless steel flat bars is set to rise in 2025. Known for its exceptional corrosion resistance and excellent machinability, 303 stainless steel is an ideal choice for applications where precision and durability are paramount. Whether you are in aerospace, automotive, or manufacturing sectors, having a reliable supply of 303 stainless steel flat bars can significantly enhance your production capabilities. When sourcing 303 stainless steel flat bars globally, it is crucial to partner with suppliers who can provide not only quality materials but also comprehensive support throughout the procurement process. From efficient logistics to industry compliance, an end-to-end solution ensures that you receive your materials on time and in perfect condition, allowing you to focus on your core business operations. With advancements in supply chain management and technology, securing these materials has never been more straightforward. Looking ahead, anticipate the increasing specialization in the production of 303 stainless steel flat bars as companies innovate and improve their processes. The future of sourcing in 2025 leverages not just product attributes but also supplier relationships, making it vital to align with partners who are committed to quality, sustainability, and customer satisfaction. This strategic approach will empower businesses to thrive in a competitive landscape while ensuring access to top-grade materials needed for success.

303 Stainless Steel Flat Bar in 2025 Your End-to-End Solution

| Dimension (mm) | Weight (kg/m) | Material Properties | Applications |

|---|---|---|---|

| 10 x 3 | 0.79 | Tensile Strength: 515 MPa | Manufacturing, Automotive |

| 20 x 5 | 1.58 | Yield Strength: 205 MPa | Construction, Marine |

| 30 x 10 | 3.58 | Corrosion Resistance: Moderate | Railways, Heavy Equipment |

| 40 x 20 | 5.18 | Hardness: 201 Brinell | Aerospace, Electrical |

| 50 x 25 | 7.78 | Ductility: High | Food Processing, Chemical |

Related Products