304 Stainless Tig Rod for Quality Welding - Best Prices & Reviews

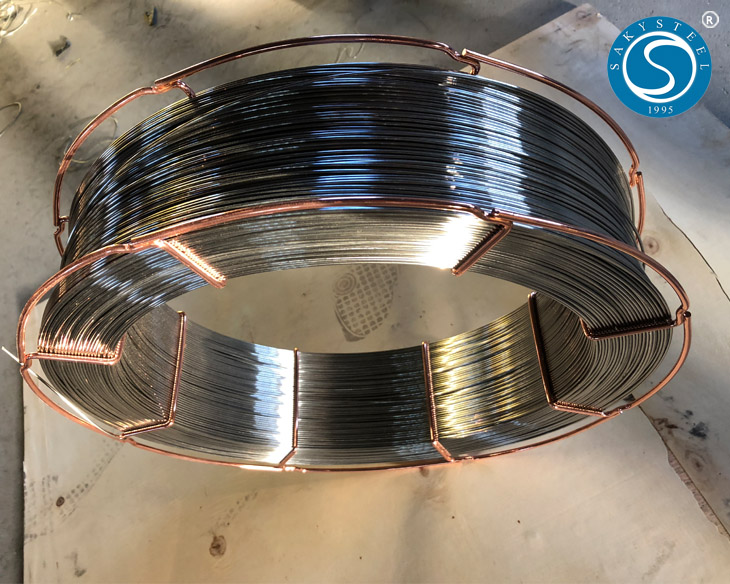

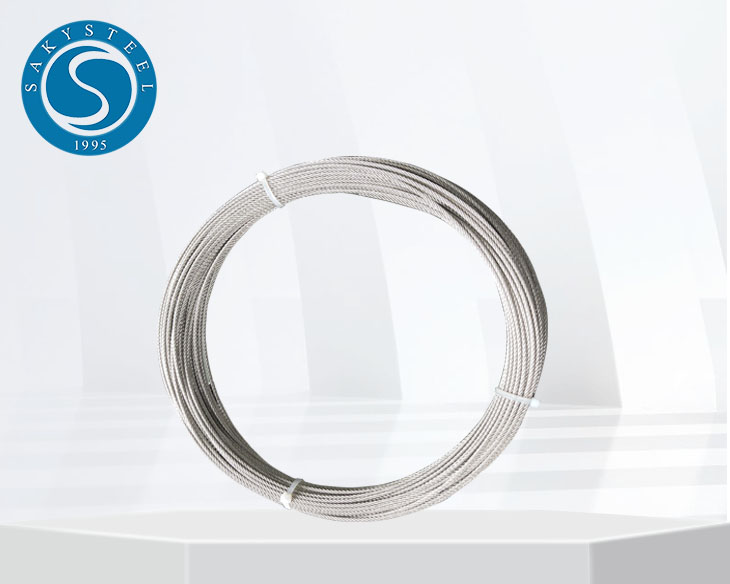

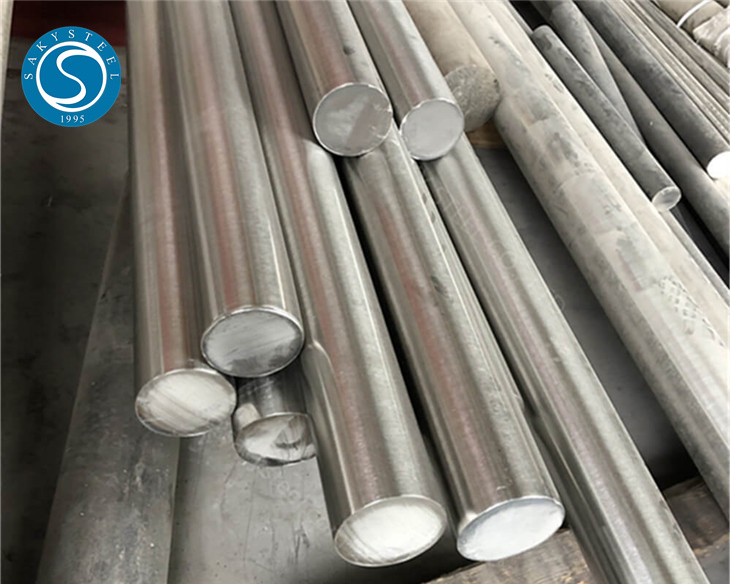

When it comes to high-quality welding, I find that 304 Stainless Tig Rod is an essential choice for any metal fabrication project. Its excellent corrosion resistance and weldability make it perfect for a variety of applications, from food processing to chemical handling. I always appreciate how it provides strong and clean welds, making my work not just easier, but also more efficient. As I explore different suppliers, the need for reliability and competitive pricing becomes clear. I want to make sure we’re not only getting the best product but also the best service in the industry. Whether you're working on a small project or a large industrial application, choosing the right tig rod can make a significant difference. Let’s elevate our welding game together with 304 Stainless Tig Rod, and ensure durability and excellence in every weld.

304 Stainless Tig Rod Your Trusted OEM Partner More Than a Supplier - A Partner

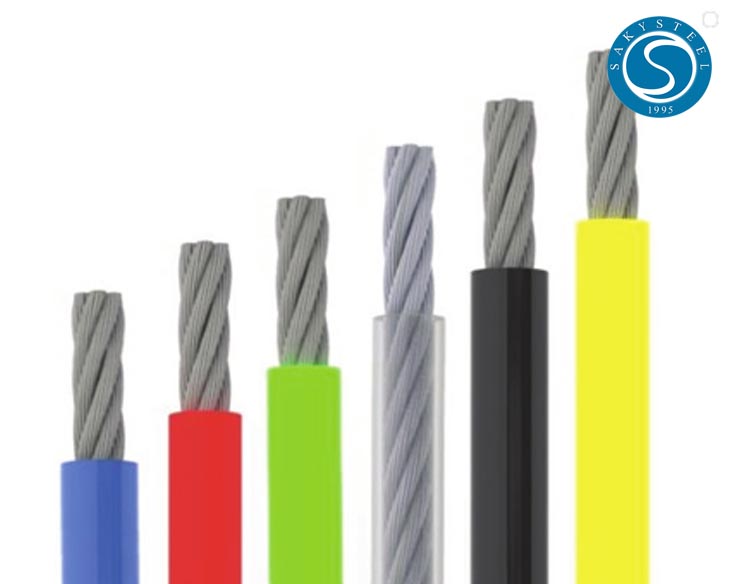

In today's competitive market, finding a reliable partner who can supply high-quality materials is crucial for the success of any project. When it comes to sourcing 304 stainless steel TIG rods, selecting a manufacturer that goes beyond mere supply to offer genuine partnership is key. These rods are essential in various applications, known for their excellent corrosion resistance and versatility, making them a staple in industries ranging from automotive to aerospace. A trusted OEM partner not only provides the necessary products but also understands the unique needs of their clients. This includes offering customized solutions, swift delivery times, and technical support throughout the procurement process. The relationship should extend beyond transactions; it should involve collaboration to optimize product specifications and enhance overall efficiency. Engaging with a manufacturer committed to quality and innovation will empower businesses to achieve their goals and navigate the complexities of global supply chains with confidence. In essence, choosing an OEM partner for your 304 stainless steel TIG rods means opting for reliability, expertise, and a commitment to shared success. This partnership can lead to significant advantages, including cost-effectiveness and improved product performance, ultimately driving greater satisfaction for both producers and end users. As you explore your options, prioritize partnerships that align with your business vision and values, ensuring that your supply chain remains robust and responsive to market demands.

304 Stainless Tig Rod Your Trusted OEM Partner More Than a Supplier - A Partner

| Dimension | Length (inches) | Diameter (mm) | Material Specification | Applications |

|---|---|---|---|---|

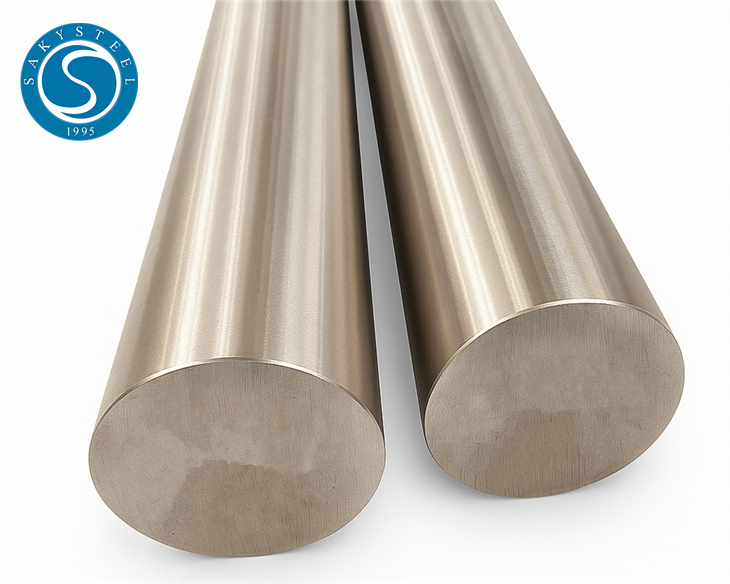

| TIG Rod | 36 | 1.6 | ASTM A276 | Food Processing |

| TIG Rod | 36 | 2.4 | ASTM A276 | Industrial Equipment |

| TIG Rod | 36 | 3.2 | ASTM A276 | Chemical Processing |

| TIG Rod | 36 | 4.0 | ASTM A276 | Automotive |

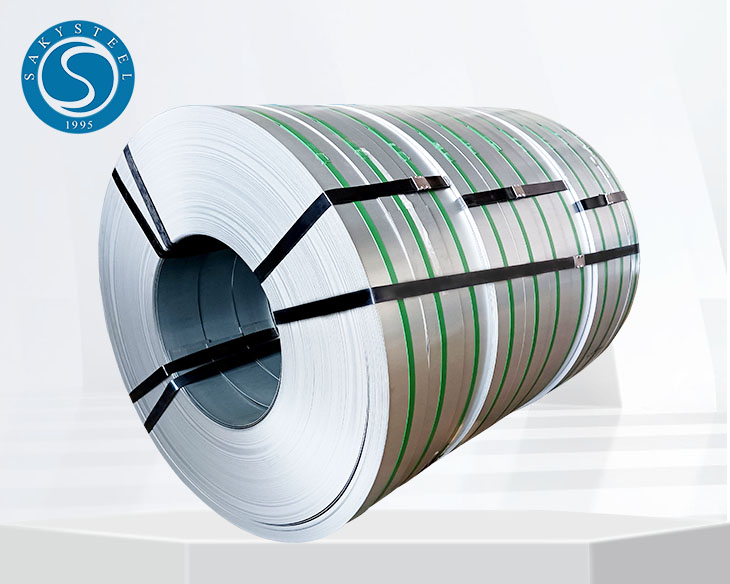

Related Products