Best 312 Stainless Tig Rod for Quality Welding and Durability

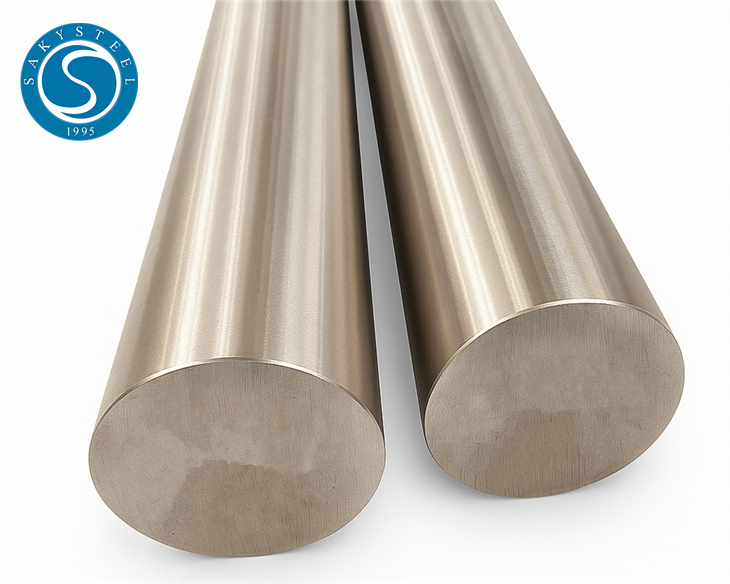

When it comes to welding, I know how crucial it is to have the right materials at hand. That’s why I highly recommend the 312 Stainless Tig Rod for your next project. With its exceptional corrosion resistance and strength, this alloy is perfect for welding dissimilar metals and ensuring strong, lasting joints. I often hear from my clients how they appreciate its easy handling and great arc stability, making it a go-to choice for both experienced welders and novices. Whether you’re a manufacturer looking for reliable welding solutions or a contractor seeking materials for specific applications, this rod meets your demands. Customers often mention its versatility, too, highlighting how well it performs in varied environments. Trust me, investing in the 312 Stainless Tig Rod can really elevate the quality of your work and increase efficiency. Let me know if you want more info or bulk pricing options!

312 Stainless Tig Rod Application Exceeds Industry Benchmarks

In the ever-evolving world of industrial materials, the performance and application of 312 stainless steel TIG rods have consistently surpassed industry benchmarks. Known for its exceptional resistance to corrosion and oxidation, this alloy is rapidly becoming the preferred choice for welding applications that require superior durability and strength. The unique composition of 312 stainless steel, which combines high chromium and nickel content, allows for excellent inter-metallic bonding, making it suitable for welding dissimilar metals and repairing components in high-temperature environments. Moreover, the versatility of 312 stainless TIG rods extends across various sectors, including petrochemical, marine, and power generation industries. Their ability to withstand extreme thermal and mechanical stresses ensures long-lasting repairs and constructions, ultimately leading to reduced downtime and maintenance costs. As global demands rise for high-quality materials, manufacturers and procurement specialists are increasingly recognizing the benefits of integrating 312 stainless steel TIG rods into their welding operations. Investing in 312 stainless TIG rods not only enhances the quality of welds but also supports sustainable practices by minimizing waste and improving the longevity of welded structures. By exceeding industry standards, these rods represent a strategic advantage for businesses aiming to stay competitive in a demanding marketplace. As the industry evolves, the choice of materials like 312 stainless steel will play a crucial role in driving innovation and efficiency across various applications.

312 Stainless Tig Rod Application Exceeds Industry Benchmarks

| Application | Heat Resistance (°C) | Corrosion Resistance | Welding Position | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| Chemical Processing | 800 | Excellent | All Positions | 620 | 40 |

| Oil and Gas | 750 | Good | Flat, Horizontal | 600 | 35 |

| Food Processing | 700 | Excellent | All Positions | 580 | 45 |

| Aerospace | 600 | Very Good | All Positions | 650 | 30 |

| Automotive | 700 | Good | Flat, Horizontal | 610 | 40 |

Related Products