410 Stainless Steel Flat Bar: Quality, Durability, and Applications

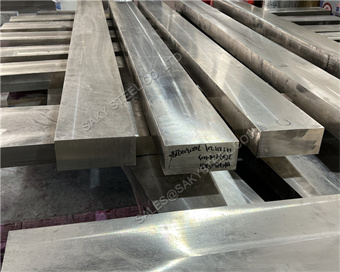

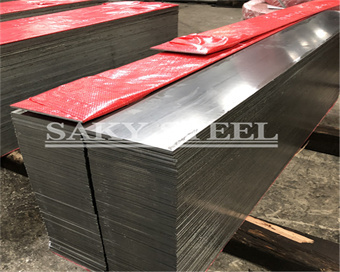

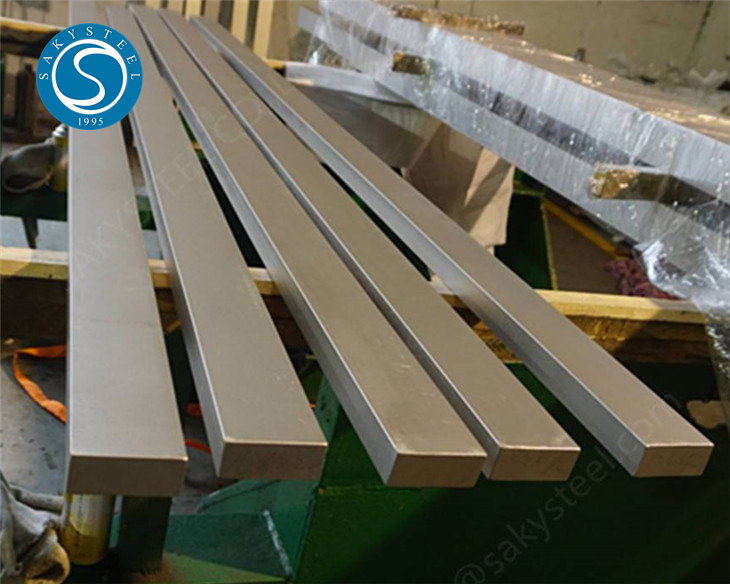

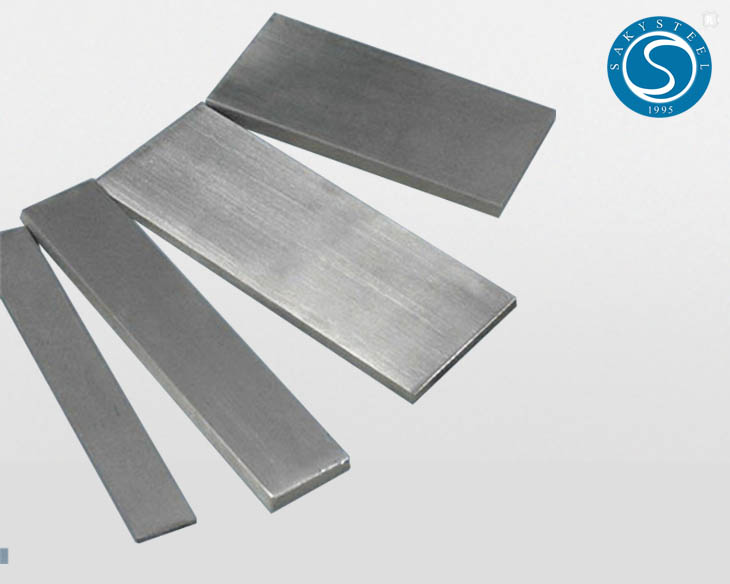

When I think about quality and durability in stainless steel products, the 410 Stainless Steel Flat Bar stands out. Ideal for a range of industrial applications, this flat bar provides excellent strength and corrosion resistance, making it perfect for environments that demand reliability. I've found it particularly useful for projects where precision and finish matter, from fabrication to structural support. I appreciate that it's easy to machine and weld, allowing for seamless integration into various manufacturing processes. If you're considering a material upgrade that combines affordability and performance, the 410 Stainless Steel Flat Bar is a smart choice. Its versatility means it fits well in both small and large-scale operations. Plus, I always trust the consistent quality that comes with this product. Whether you're in construction, automotive, or manufacturing, this flat bar can meet your needs. Don't hesitate to reach out for more details!

410 Stainless Steel Flat Bar For the Current Year More Than a Supplier - A Partner

In today's competitive market, sourcing high-quality materials is crucial for sustaining business growth and meeting customer demands. When it comes to stainless steel, specifically 410 stainless steel flat bars, partnering with a reliable supplier is more important than ever. These flat bars boast excellent strength, corrosion resistance, and versatility, making them ideal for various applications, from automotive to construction. However, a supplier should do more than merely provide products; they should serve as a strategic partner who understands your unique needs and collaborates with you to fulfill them. Choosing a partner that offers not just products but comprehensive solutions can significantly impact your operational efficiency and product quality. The ideal partner will provide value-added services, such as expert technical support, quick turnaround times, and customized solutions tailored to your specific industry requirements. By fostering a collaborative relationship, you can benefit from their industry insights and innovations, helping you stay ahead of market trends. Moreover, a strong partnership ensures that you receive consistent quality control, timely deliveries, and competitive pricing, which are essential for maintaining your supply chain's integrity. As we navigate through the current year, it is paramount for procurement professionals to seek partners who prioritize transparency and sustainability in their operations. Reliable partnerships can lead to enhanced product performance, improved sustainability practices, and, most importantly, the achievement of shared business objectives. In the realm of stainless steel procurement, consider not only the materials but the long-term relationship and support your supplier can provide—turning a transactional experience into a mutually beneficial partnership.

410 Stainless Steel Flat Bar For the Current Year More Than a Supplier - A Partner

| Dimension (mm) | Applications | Benefits | Compliance Standards | Finish |

|---|---|---|---|---|

| 20 x 5 | Construction | Corrosion Resistance | ASTM A276 | Mill Finish |

| 50 x 10 | Automotive | High Strength | ASTM A240 | Brushed Finish |

| 75 x 20 | Manufacturing | Malleability | ISO 9001 | Polished Finish |

| 100 x 25 | Marine | Durability | ASTM A554 | Passivated Finish |

Related Products