Top Elbow Stainless Options for Quality and Durability

When I think about quality and durability, I always recommend Elbow Stainless fittings. These premium-grade elbows are essential for any piping project, offering unmatched resistance to corrosion and high temperatures. Whether you're expanding your manufacturing processes or working on a new construction project, these fittings provide the reliability you need. I often hear from clients that they appreciate the precision engineering that guarantees a perfect fit every time. With competitive pricing and bulk order options, sourcing Elbow Stainless for your business has never been easier. I know how important it is for B2B purchasers to find suppliers that understand their needs. That's why I emphasize quality assurance and customer support with every order. You’ll find that the performance of our elbows not only meets but exceeds industry standards. Transform your operations with fittings that truly deliver long-lasting results. Let's ensure your projects run smooth and efficient with Elbow Stainless!

Elbow Stainless Industry Giant Custom Solutions,

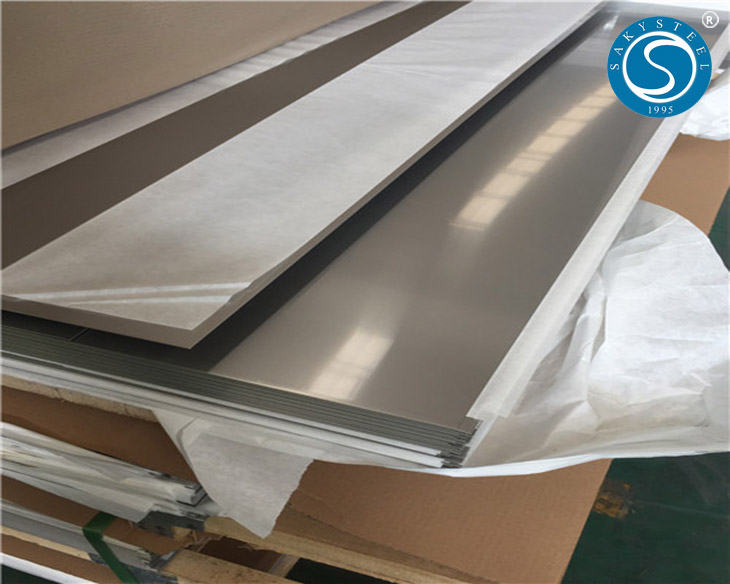

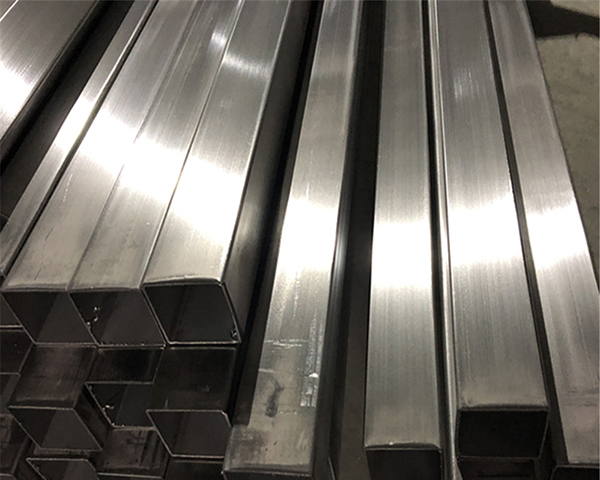

In today's global market, the demand for high-quality stainless steel solutions is consistently on the rise. Industries across the board are seeking reliable partners who can provide not only exceptional products but also tailored solutions to meet their specific needs. This is where the expertise in custom stainless steel solutions becomes invaluable. Offering a diverse range of elbow fittings and components, manufacturers can cater to various applications, including construction, automotive, and manufacturing sectors. Elbow fittings are integral to any piping system, allowing for efficient direction changes while minimizing pressure loss and potential leaks. When sourcing these components, global buyers prioritize durability, corrosion resistance, and precise engineering. Custom solutions can significantly enhance operational efficiency by ensuring compatibility with existing systems and optimizing fluid flow. By collaborating with experienced suppliers, businesses can access innovative designs and cutting-edge technology that elevate their project outcomes. In an era where sustainability and cost-effectiveness are paramount, selecting the right supplier for stainless steel solutions means investing in long-term partnerships that prioritize quality and reliability. Understanding the unique challenges of different industries enables suppliers to offer tailored products that not only meet specifications but also drive success in increasingly competitive markets. As you explore potential partners, consider the added value of custom solutions in fulfilling your operational needs while supporting your strategic objectives.

Elbow Stainless Industry Giant Custom Solutions

| Dimension | Material Type | Surface Finish | Standard | Application |

|---|---|---|---|---|

| 1/2 inch | 316 Stainless Steel | Polished | ASTM A312 | Food Processing |

| 3/4 inch | 304 Stainless Steel | Brushed | ASME B16.9 | Chemical Plant |

| 1 inch | Duplex Stainless Steel | As-Welded | ASTM A928 | Oil and Gas |

| 1 1/2 inch | Nickel Alloy | Passivated | ASTM B366 | Marine Applications |

| 2 inch | Carbon Steel | Coated | ASTM A234 | Construction |

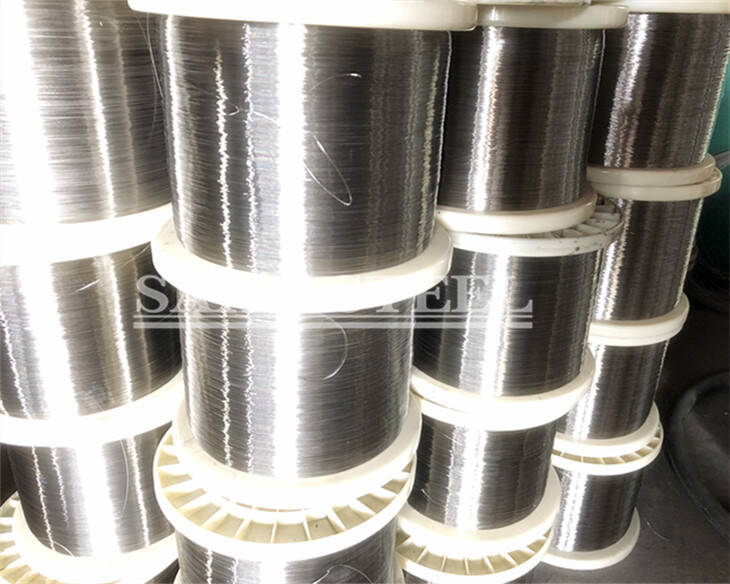

Related Products