Er70s6 Tig Rod: Best Performance for Precision Welding Projects

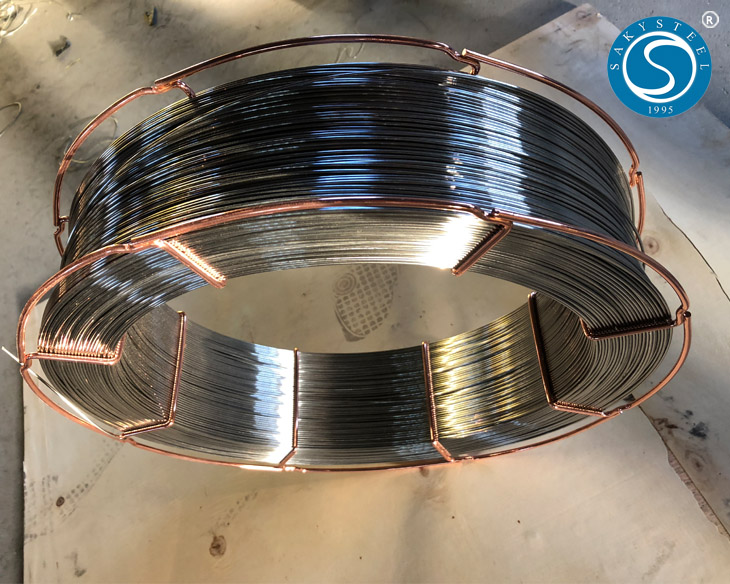

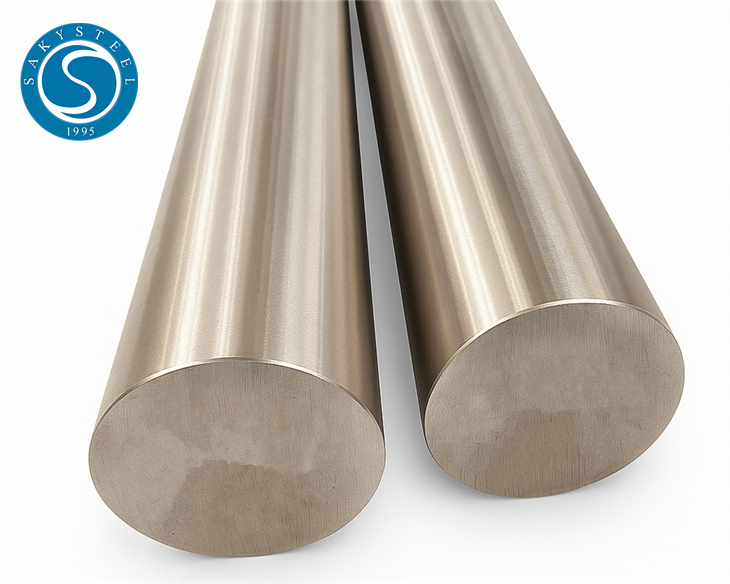

When I first came across the ER70S-6 TIG rod, I knew it was a game changer for my welding projects. This rod offers exceptional versatility, making it perfect for welding mild steel and various other materials. I’ve noticed how easily it flows during the welding process, giving me smooth and strong welds that hold up under pressure. Many B2B purchasers find that the ER70S-6's excellent feedability and minimal spatter means less cleanup time and higher productivity. Plus, it’s ideal for applications requiring tough, ductile welds, which I appreciate. Whether you’re working with thin or thick sections, this rod can handle it all. Choosing this product means investing in quality and reliability, which I’ve seen reflected in the performance of my own welds. It’s definitely the right choice for anyone looking to enhance their welding efficiency and effectiveness. If you’re serious about your work, the ER70S-6 TIG rod is something you should not overlook!

Er70s6 Tig Rod Industry Leaders Factory-Direct Excellence

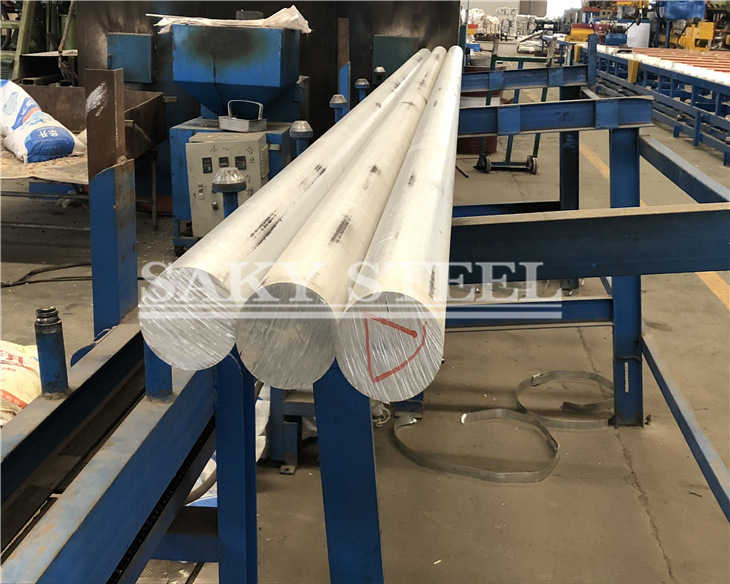

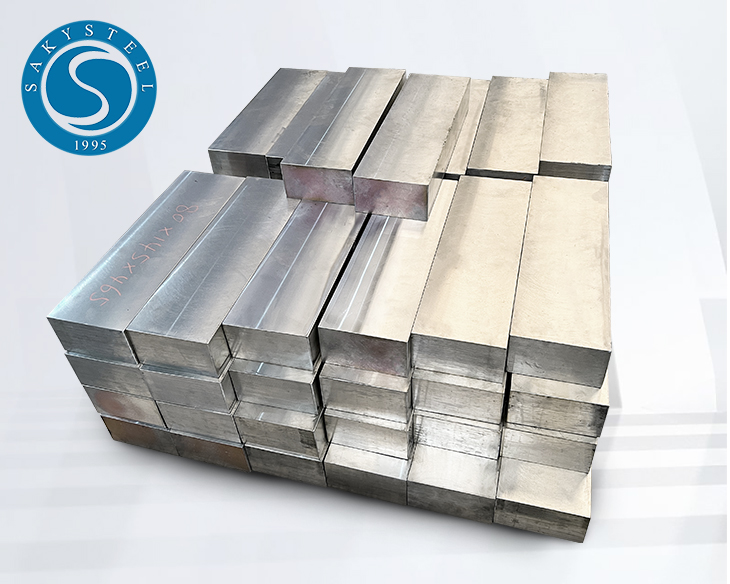

In the ever-evolving landscape of welding materials, the demand for reliable and high-quality TIG rods such as ER70S-6 is on the rise. Businesses around the globe are seeking suppliers who not only deliver exceptional products but also understand the nuances of the welding industry. This is where factory-direct excellence comes into play. By sourcing directly from manufacturers, buyers benefit from enhanced quality control, reduced costs, and a streamlined supply chain, ensuring timely delivery of materials that meet strict industry standards. The ER70S-6 TIG rod is renowned for its versatility and performance, making it a top choice for various welding applications, particularly in the automotive and construction sectors. The seamless manufacturing processes employed ensure that every rod maintains consistent mechanical properties and optimal corrosion resistance. With a focus on precision and reliability, sourcing these rods directly from industry leaders guarantees that procurement decisions are backed by quality assurance and extensive industry expertise. As global procurement evolves, it is essential for buyers to prioritize partnerships with manufacturers that can provide not only products but also comprehensive support and insight into welding advancements. Choosing the right supplier can make all the difference in operational efficiency and project success. By embracing factory-direct excellence, procurement professionals can ensure they are equipped with the best materials to meet their project demands, driving innovation and success in their respective fields.

Er70s6 Tig Rod Industry Leaders Factory-Direct Excellence

| Material Type | Diameter (mm) | Length (mm) | Tensile Strength (MPa) | Elongation (%) | Packaging Type |

|---|---|---|---|---|---|

| ER70S-6 | 1.6 | 1000 | 490 | 20 | Spool |

| ER70S-6 | 2.4 | 1500 | 485 | 19 | Coil |

| ER70S-6 | 3.2 | 2000 | 480 | 18 | Box |

| ER70S-6 | 4.0 | 2500 | 475 | 17 | Reel |

| ER70S-6 | 5.0 | 3000 | 470 | 16 | Case |

Related Products