Stainless Filler Rod - Essential Guide for Welding Projects & Quality Choices

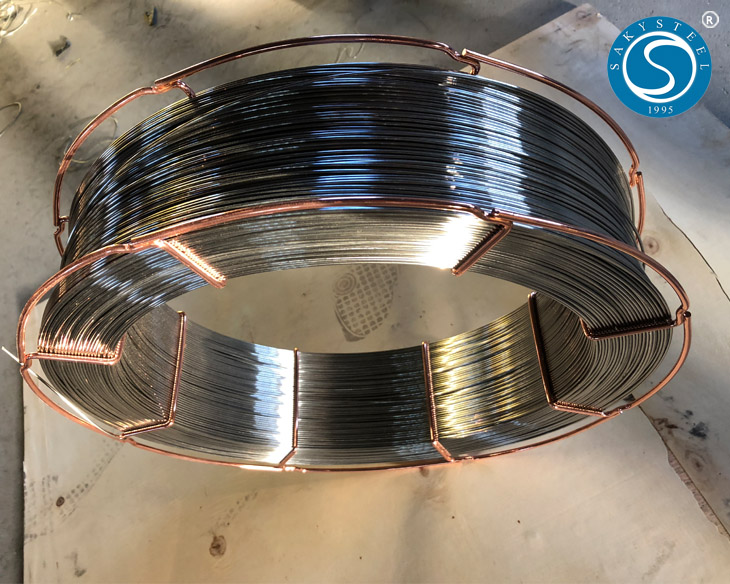

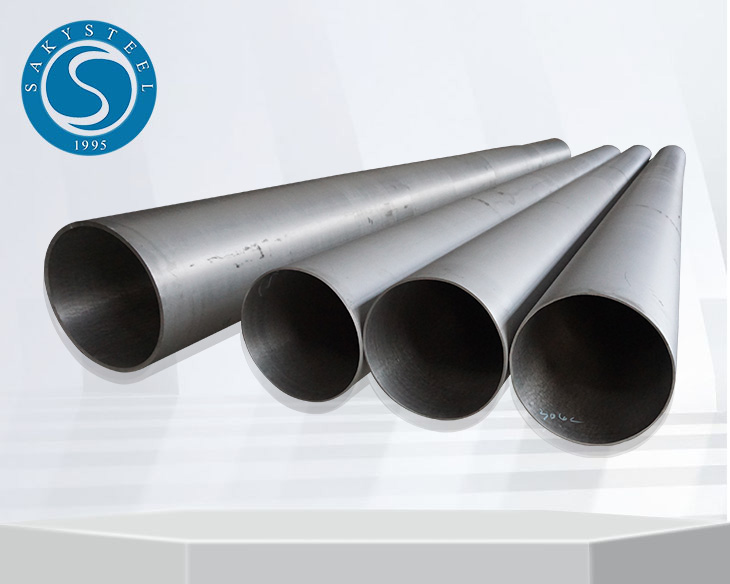

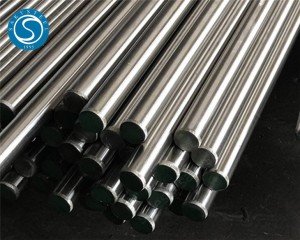

When I think about high-performance welding, the Stainless Filler Rod comes to mind as the perfect ally for any project. I’ve experienced firsthand how essential it is for achieving strong, reliable joins in stainless steel applications. With its excellent corrosion resistance, using this filler rod not only enhances durability but also maintains the aesthetic appeal of the welds. Whether you’re involved in manufacturing, construction, or maintenance, I know how vital it is to have the right tools at your disposal. That’s why I highly recommend our Stainless Filler Rod for your fabricating needs. Its compatibility with various welding processes makes it a must-have, especially for those focused on precision and quality. Pairing these rods with superior techniques can lead to impressive results. If you're mainly looking for strength and reliability, you'd be making a wise choice. Don't miss the chance to elevate your welding projects – the results speak for themselves!

Stainless Filler Rod Factory Pioneers in the Field

In the ever-evolving landscape of manufacturing, the demand for high-quality stainless filler rods has reached new heights. These rods are essential components in various industries, including automotive, aerospace, and construction, where durability and corrosion resistance are paramount. By prioritizing advanced production techniques and stringent quality control, companies are ensuring that their products not only meet but exceed international standards. The innovative approaches adopted in manufacturing stainless filler rods include the use of high-grade raw materials and state-of-the-art machinery. This not only enhances the mechanical properties of the rods but also streamlines the supply chain, allowing for quicker delivery times to global buyers. Additionally, the commitment to sustainability is reshaping production processes, making them more environmentally friendly while maintaining efficiency. As businesses across the globe seek reliable sources for their welding needs, choosing a leader in the stainless filler rod sector can significantly impact operational efficiency and profitability. By collaborating with a pioneer in this field, buyers can gain access to a comprehensive range of products tailored to diverse applications, backed by a legacy of excellence and innovation.

Stainless Filler Rod Factory Pioneers in the Field

| Metric | Details |

|---|---|

| Material Type | Stainless Steel |

| Diameter Range (mm) | 1.0 - 3.2 |

| Applications | Welding, Fabrication, Repair |

| Certification | ISO 9001 |

| Country of Origin | China |

| Production Capacity (tons/year) | 5000 |

| Lead Time (days) | 30 |

Related Products