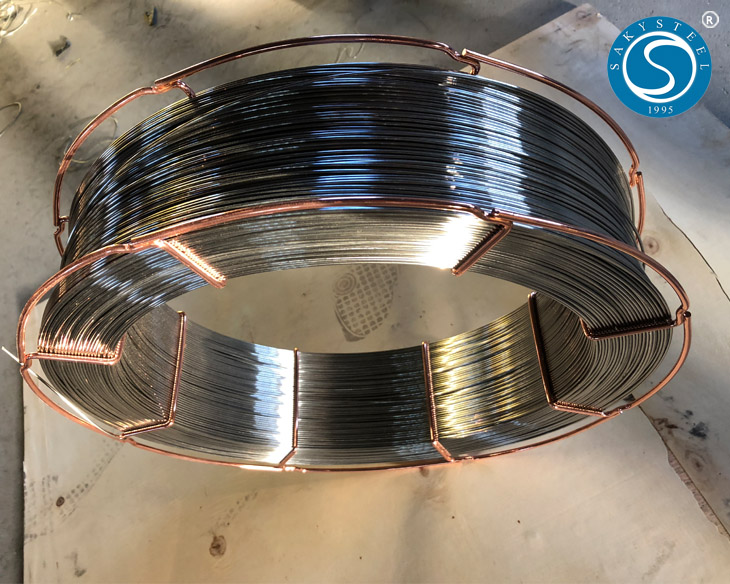

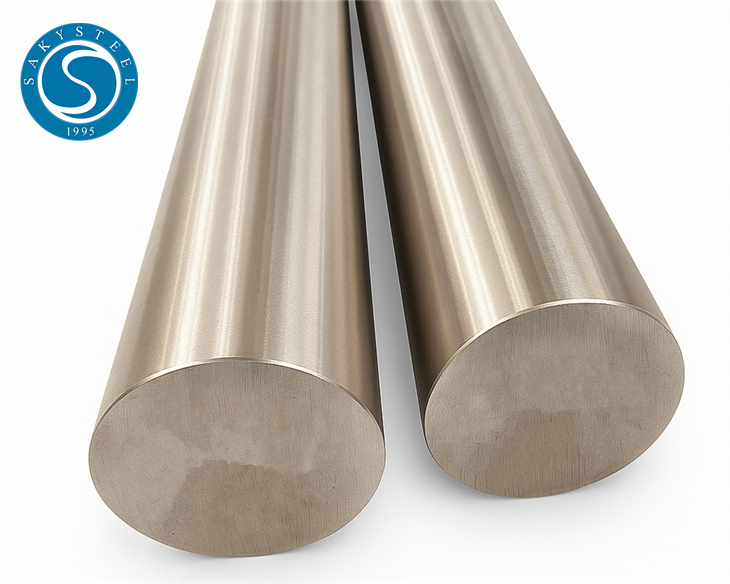

Premium Stainless Steel Tig Rods for High-Performance Welding Needs

When it comes to high-quality welding, I trust Stainless Steel Tig Rods for precision and strength. These rods are essential for my projects, offering exceptional performance and durability in stainless steel applications. Whether I’m working on intricate designs or structural components, these rods provide a clean, consistent finish, making my welds stand out. I appreciate that they’re crafted for easy handling, and their compatibility with various stainless steel grades allows me to tackle any job with confidence. Plus, knowing they are sourced from a reliable supplier helps me focus on my work, not on sourcing issues. Ideal for industries like manufacturing and repair, these rods enhance my workflow. With their robust structure and ease of use, it's no wonder they are a favorite among professionals like me. Invest in Stainless Steel Tig Rods, and elevate the quality of your work today!

Stainless Steel Tig Rod Application Winning in 2025

As the landscape of manufacturing and construction evolves, the application of stainless steel TIG rods in various industries is poised to revolutionize production processes by 2025. These rods are not just tools; they are essential components that enhance the efficiency and durability of welded products. With their resistance to corrosion and high heat tolerance, stainless steel TIG rods provide manufacturers with reliable solutions for creating high-quality welds, especially in sectors such as automotive, aerospace, and shipbuilding. The demand for such materials is set to rise as industries prioritize sustainability and longevity in their manufacturing practices. In 2025, companies that embrace advanced welding techniques using stainless steel TIG rods will have a competitive edge. The technology behind TIG welding, combined with the superior qualities of stainless steel, allows for cleaner and more precise welds. This precision is crucial as industries increasingly look to minimize material waste and improve production timelines. Additionally, as governments and organizations worldwide implement stricter regulations on emissions and environmental impact, the shift toward high-performance, eco-friendly materials like stainless steel will only accelerate. For global buyers, investing in stainless steel TIG rods is a strategic move. Not only do these rods ensure higher durability and performance, but they also align with the growing trend of investing in materials that support sustainable manufacturing. As we look towards 2025, the focus on quality, efficiency, and sustainability through the use of stainless steel TIG rods will shape the future of welding applications. Adopting these innovative solutions can significantly enhance product offerings and pave the way for success in a highly competitive global market.

Stainless Steel Tig Rod Application Winning in 2025

| Application | Material Type | Diameter (mm) | Heat Resistance (°C) | Current Type |

|---|---|---|---|---|

| Aerospace Components | 304 Stainless Steel | 2.4 | 800 | AC/DC |

| Food Processing Equipment | 316L Stainless Steel | 1.6 | 750 | AC |

| Marine Applications | Duplex Stainless Steel | 3.2 | 700 | DC |

| Automotive Parts | 430 Stainless Steel | 2.0 | 650 | AC/DC |

| Construction and Infrastructure | 309L Stainless Steel | 1.2 | 900 | AC |

Related Products