Top Stainless Tig Rods for Expert Welding - Quality & Performance

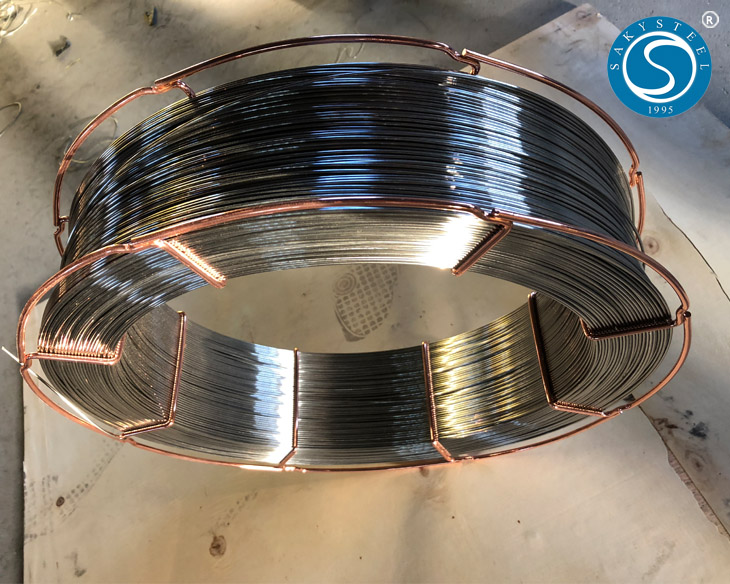

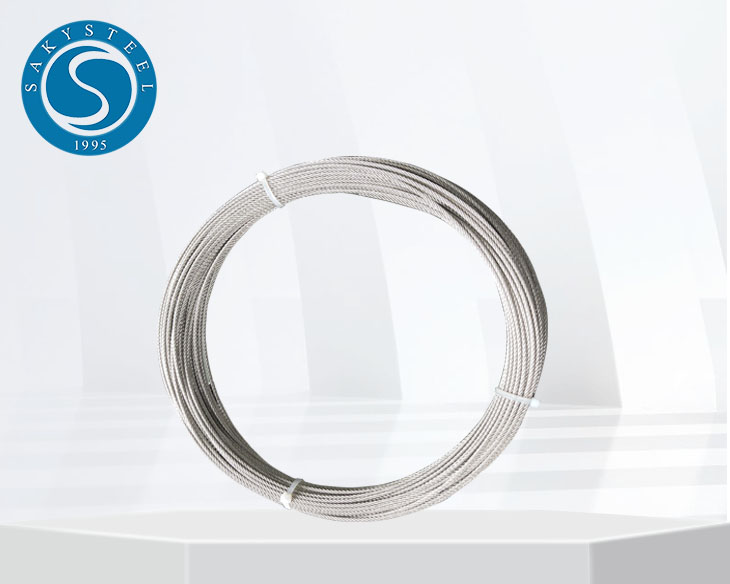

When it comes to precision welding, I can’t stress enough the importance of choosing the right materials. That’s why I always recommend our Stainless Tig Rods. These rods offer exceptional corrosion resistance and strength, making them ideal for your toughest projects. I’ve found that they provide outstanding arc stability and a smooth finish, which really makes a difference in the final product. I know many of my colleagues have been searching for reliable options, and these rods have consistently met their high expectations. Whether you’re in construction, manufacturing, or any industry that demands quality welds, our Stainless Tig Rods will elevate your work. Plus, with competitive pricing and bulk purchase options available, they’re perfect for businesses looking to optimize costs without sacrificing quality. Trust me, once you try our rods, you won’t want to go back to anything else. Your projects deserve the best, and this is it!

Stainless Tig Rod Pioneers in the Field Sets the Industry Standard

In the highly specialized world of stainless TIG rods, few companies have carved a niche like pioneers who consistently set industry standards. These innovators understand the intricate balance between quality, performance, and reliability, making them invaluable partners for global buyers. The tungsten inert gas (TIG) welding process requires materials that not only meet rigorous structural demands but also maintain excellent corrosion resistance, enabling projects in diverse environments, from marine applications to chemical processing. The commitment to excellence in manufacturing stainless TIG rods has led to enhanced product offerings that incorporate advanced technology and rigorous testing protocols. Buyers can expect materials that deliver superior arc stability, minimal spatter, and exceptional bead appearance, contributing to high-quality welds that stand the test of time. Moreover, the ability to customize these rods according to specific project requirements highlights the flexibility and responsiveness of these industry leaders, catering directly to the needs of clients around the globe. Furthermore, sustainability is becoming a pivotal focus, with pioneers leading the charge towards environmentally-friendly production processes. By investing in eco-conscious practices, they not only support global sustainability goals but also appeal to an increasingly discerning market that values responsible sourcing. As global procurement chains become more interconnected, aligning with pioneers in the field ensures access to top-tier products that not only meet but exceed expectations, solidifying partnerships that drive mutual growth and success.

| Rod Type | Material | Diameter (mm) | Applications | Certification |

|---|---|---|---|---|

| ER308L | Stainless Steel | 1.6 | Food Processing, Chemical Industry | AWS A5.9 |

| ER316L | Stainless Steel | 2.4 | Marine, Pharmaceutical | ASME SFA-5.9 |

| ER347 | Stainless Steel | 3.2 | Aerospace, High-Temperature Applications | ISO 9001 |

| ER309L | Stainless Steel | 1.0 | Welds Dissimilar Metals | AWS A5.9 |

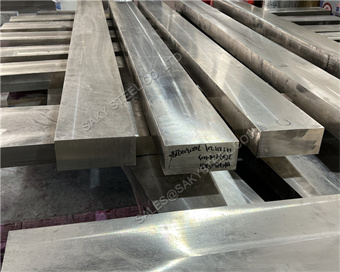

Related Products