Beam ea tšepe e sa hloekang ea HI

Tlhaloso e Khutšoanyane:

"H Beam" e bolela likarolo tsa sebopeho tse bōpehileng joaloka tlhaku "H" tse sebelisoang ka ho fetisisa mohahong le lits'ebetsong tse fapaneng tsa sebopeho.

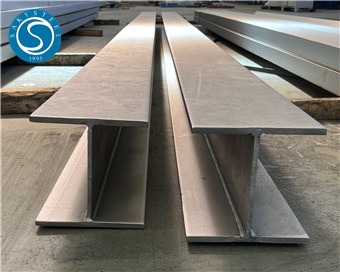

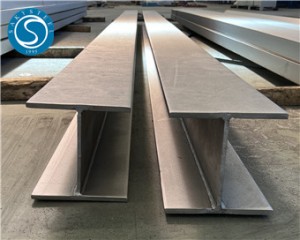

Beam ea Stainless Steel H:

Stainless steel H Beam ke likarolo tsa sebopeho tse khetholloang ka karolo ea tsona ea sebopeho sa H.Likanale tsena li entsoe ka tšepe e sa hloekang, e leng motsoako o hanang ho bola, o tsejoang ka ho tšoarella ha oona, bohloeki le bokhabane ba oona.Likanale tsa tšepe tse sa hloekang tsa H li fumana lits'ebetso liindastering tse fapaneng, ho kenyeletsoa kaho, meaho, le tlhahiso, moo ho hanyetsa ha kutu le matla a tsona li li etsang khetho e ratoang bakeng sa ts'ehetso ea meralo le moralo.Likaroloana tsena hangata li sebelisoa kahong ea meralo, litšehetso, le tse ling. likarolo tsa sebopeho moo matla le ponahalo e bentšitsoeng li leng bohlokoa.

Litlhaloso tsa I Beam:

| Kereiti | 302 304 304L 310 316 316L 321 2205 2507 joalo-joalo. |

| Standard | GB T33814-2017,GBT11263-2017 |

| Bokaholimo | Ho qhomisa lehlabathe, ho bentša, ho qhomisa lithunya |

| Thekenoloji | Hot Rolled , Welded |

| Bolelele | 1 ho 12 Limithara |

Websaete:

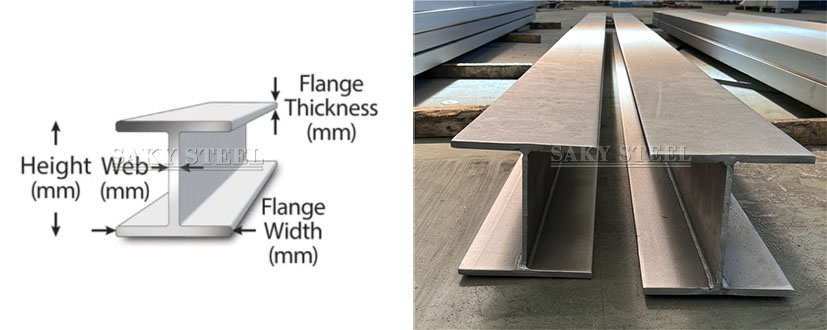

Webo e sebetsa e le khubu e bohareng ea leballo, hangata e hlophisoa ho latela botenya ba eona.E sebetsa joalo ka sehokelo sa meralo, e phetha karolo ea bohlokoa ho baballeng bots'epehi ba leballo ka ho hokahanya le ho kopanya mahlakore a mabeli, ho aba le ho laola khatello ka katleho.

Flange:

Likarolo tse ka holimo le tse bataletseng tse ka tlaase tsa tšepe li jara mojaro o ka sehloohong.Ho etsa bonnete ba kabo e tšoanang ea khatello, re batalatsa li-flanges.Likarolo tsena tse peli li tsamaisana ka mokhoa o ts'oanang, 'me moelelong oa maballo a I, li na le likeketso tse kang mapheo.

H Beam Welded Line Tekanyo ea botenya:

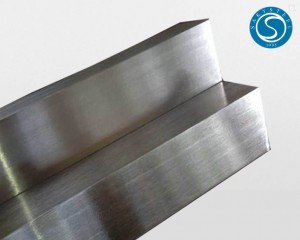

Ts'ebetso ea Stainless Steel I Beam Beveling:

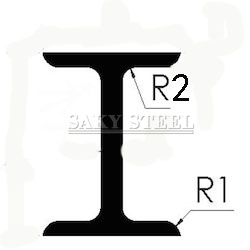

R angle ea I-beam e bentšitsoe ho etsa hore bokaholimo bo be boreleli 'me bo se ke ba burr, e leng ntho e loketseng ho sireletsa polokeho ea basebetsi.Re ka sebetsana le angle ea R ea 1.0, 2.0, 3.0.304 316 316L 2205 Stainless Steel IH Mabala.Li-angles tsa R tsa mela e 8 kaofela li bentšitsoe.

Stainless Steel I Beam Wing/Flange e otlolohileng:

Likarolo le Melemo:

•Sebopeho sa "H" se nang le sebopeho se sephara sa tšepe ea I-beam se fana ka bokhoni bo ikhethang ba ho jara meroalo e otlolohileng le e otlolohileng.

•Sebopeho sa sebopeho sa tšepe ea I-beam se fana ka boemo bo phahameng ba botsitso, ho thibela deformation kapa ho khumama tlas'a khatello ea maikutlo.

•Ka lebaka la sebopeho sa eona se ikhethang, tšepe ea I-beam e ka sebelisoa habonolo ho meaho e fapaneng, ho kenyelletsa maballo, litšiea, marokho le tse ling.

•I-beam tšepe e sebetsa ka mokhoa o ikhethang ka ho kobeha le ho hatella, ho netefatsa botsitso tlas'a maemo a thata a ho laela.

•Ka moralo oa eona o sebetsang hantle le matla a phahameng, tšepe ea I-beam hangata e fana ka litšenyehelo tse ntle.

•I-beam steel e fumana ts'ebeliso e kholo ho tsa kaho, marokho, lisebelisoa tsa indasteri, le mafapheng a mang a fapaneng, e bonts'a ho feto-fetoha ha eona ho merero e fapaneng ea boenjiniere le ea meralo.

•Moqapi oa tšepe ea I-beam o o lumella ho ikamahanya hantle le litlhoko tsa kaho e tsitsitseng le moralo, ho fana ka tharollo e sebetsang ea sebopeho bakeng sa mekhoa e metle ea tikoloho le e tala.

Sebopeho sa Lik'hemik'hale H Beam:

| Kereiti | C | Mn | P | S | Si | Cr | Ni | Mo | Naetrojene |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical thepa ea I Beams:

| Kereiti | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo.Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa hore re tla fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

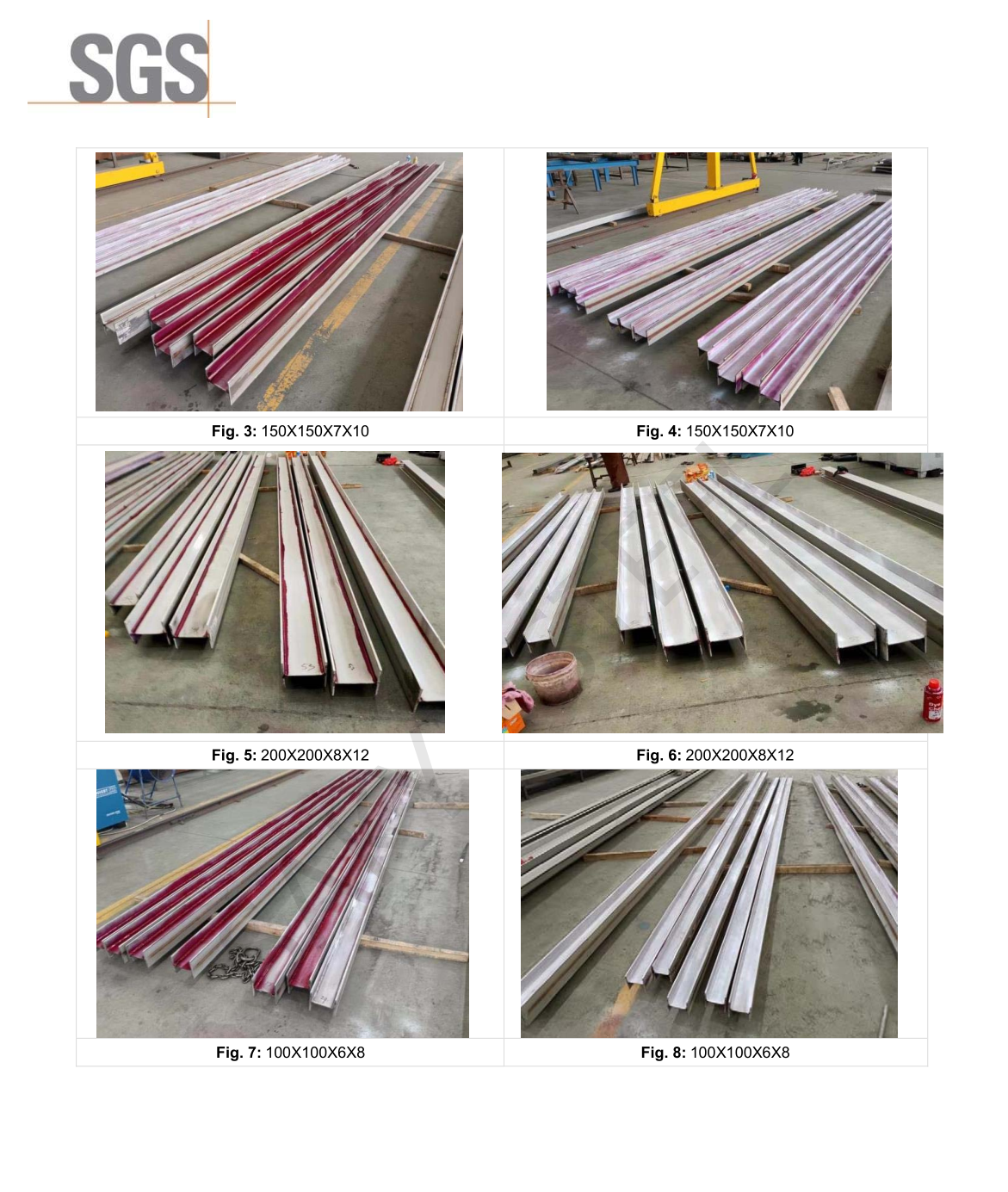

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona.Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Teko ea 316L ea tšepe e sa hloekang e cheselitsoeng H Beam Penetration test (PT)

Motheo ho JBT 6062-2007 Teko e sa senyeheng - tlhahlobo e kenang ea li-welds bakeng sa 304L 316L tšepe e sa hloekang e entsoeng ka H Beam.

Mekhoa ea ho cheselletsa ke efe?

Mekhoa ea ho tjheseletsa e kenyelletsa welding ea arc, welding e sirelelitsoeng ka khase (MIG/MAG welding), welding ea ho hanyetsa, laser welding, plasma arc welding, friction stir welding, khatello ea khatello, electron beam welding, joalo-joalo. mefuta ea li-workpieces le litlhoko tsa tlhahiso.A arc e sebelisetsoa ho hlahisa mocheso o phahameng, ho qhibilihisa tšepe holim'a setsi sa mosebetsi ho theha khokahanyo.Mekhoa e tloaelehileng ea li-arc welding e kenyelletsa li-arc welding manual, argon arc welding, submerged arc welding, joalo-joalo Mocheso o hlahisoang ke ho hanyetsa o sebelisetsoa ho qhibilihisa tšepe holim'a mochini oa mosebetsi ho theha khokahanyo.Resistance welding e kenyelletsa welding ea matheba, seam welding le bolt welding.

Melemo ea ho cheseletsa ka tlas'a metsi ke efe?

Arc welding e ka tlas'a metsi e loketse ho iketsetsa le maemo a phahameng.E ka phethela palo e kholo ea mosebetsi oa ho cheselletsa ka nako e batlang e le khuts'oane le ho ntlafatsa katleho ea tlhahiso.Arc welding e ka tlas'a metsi e loketse ho iketsetsa le maemo a phahameng.E ka phethela palo e kholo ea mosebetsi oa ho cheselletsa ka nako e batlang e le khuts'oane le ho ntlafatsa katleho ea tlhahiso.Arc welding e ka tlas'a metsi hangata e sebelisoa ho tjheseletsa lishiti tse teteaneng tsa tšepe hobane ho kenella ha eona ho phahameng hona joale le ho phahameng ho etsa hore e sebetse haholoanyane lits'ebetsong tsena.Kaha weld e koahetsoe ke flux, oksijene e ka thibeloa ka katleho ho kena sebakeng sa weld, kahoo ho fokotsa monyetla oa ho ba le oxidation le spatter. bokgoni ba basebetsi.Ka har'a li-arc welding tse ka tlas'a metsi, lithapo tse ngata tsa welding le li-arcs li ka sebelisoa ka nako e le 'ngoe ho fihlela welding ea li-channel tse ngata (multi-layer) le ho ntlafatsa katleho.

Ts'ebeliso ea maballo a Stainless Steel H ke afe?

Maballo a tšepe e sa hloekang a sebelisoa haholo meahong, boenjiniere ba leoatle, lisebelisoa tsa indasteri, likoloi, merero ea matla le likarolo tse ling ka lebaka la ho hanyetsa kutu le ho tšoarella nako e telele.Ba fana ka ts'ehetso ea meralo mererong ea kaho 'me ba bapala karolo ea bohlokoa tikolohong e hlokang ho senngoa ke kutu, joalo ka maemo a leoatle kapa indasteri.Ho feta moo, ponahalo ea bona ea sejoale-joale le botle bo botle e ba etsa hore ba tšoanelehe bakeng sa lits'ebetso tsa meralo ea kaho le ea kahare.

Beam ea Stainless Steel HI e otlolohile hakae?

Ho otloloha ha tšepe ea H-beam, joalo ka karolo efe kapa efe ea meralo, ke ntlha ea bohlokoa ts'ebetsong ea eona le ts'ebetsong ea eona.Ka kakaretso, bahlahisi ba hlahisa li-beams tsa tšepe tse sa hloekang tsa H ka tekanyo e itseng ea ho otloloha ho finyella litekanyetso tsa indasteri le litlhaloso.

Tekanyetso e amohelehang ea indasteri bakeng sa ho otloloha ka tšepe ea sebopeho, ho kenyelletsa le marako a tšepe a sa hloekang a H, hangata a hlalosoa ka mokhoa oa ho kheloha ho amohelehang ho tloha moleng o otlolohileng ho feta bolelele bo itseng.Ho kheloha hona hangata ho hlalosoa ho latela limilimithara kapa lisenthimithara tsa ho fiela kapa ho falla ha lehlakore.

Selelekela ho sebopeho sa H beam ?

Sebopeho sa sefapano sa I-beam steel, seo hangata se tsejoang e le "工字钢" (gōngzìgāng) ka Sechaena, se tšoana le tlhaku "H" ha e buloa.Haholo-holo, karolo ea sefapano hangata e na le mekoallo e 'meli e tšekaletseng (li-flange) holimo le tlase le bar e emeng e bohareng (tepo).Sebopeho sena sa "H" se fana ka matla a phahameng le botsitso ho tšepe ea I-beam, e etsang hore e be ntho e tloaelehileng ea mohaho oa mohaho le boenjiniere. e le maballo, litšiea, le mehaho ea borokho.Sebopeho sena sa sebopeho se nolofalletsa tšepe ea I-beam ho aba meroalo ka katleho ha e tlas'a matla, e fana ka tšehetso e matla.Ka lebaka la sebopeho sa eona se ikhethang le litšobotsi tsa sebopeho, tšepe ea I-beam e fumana ts'ebeliso e atileng masimong a kaho le boenjiniere.

Mokhoa oa ho hlalosa boholo le polelo ea I-beam?

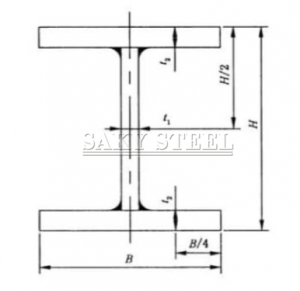

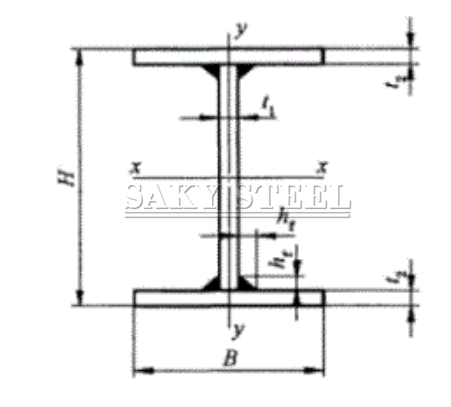

Ⅰ.Papiso ea likarolo tse fapaneng le matšoao a 316L tšepe e sa jeleng paate e entsoeng ka sebopeho sa H:

H——Bophahamo

B——Bophara

t1——Web botenya

t2—— Botenya ba poleiti ea flange

h £——Saese ya welding(ha o sebedisa motswako wa butt le fillet welds, e lokela ho ba boholo bo matlafaditsweng ba leoto la hk)

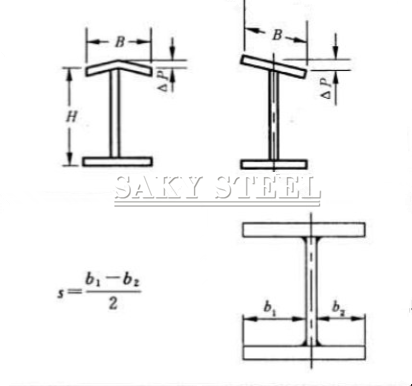

Ⅱ.Litekanyo, libopeho le liphapang tse lumelletsoeng tsa tšepe ea 2205 duplex welded e nang le sebopeho sa H:

| H Beam | Mamello |

| Tlckness (H) | Helight 300 kapa ka tlase ho moo: 2.0 mmHo feta 300:3.0mm |

| Bophara (B) | 2.0 limilimithara |

| Perpendicularlty (T) | 1.2% kapa ka tlase ho wldth (B)Hlokomela hore mamello e nyane ke 2.0 mm |

| Offset ea setsi (C) | 2.0 limilimithara |

| Ho kobeha | 0.2096 kapa ka tlase ho bolelele ba eona |

| Bolelele ba leoto (S) | [web plate thlckness (t1) x0.7]kapa ho feta |

| Bolelele | 3 ~ 12m |

| Mamello ya bolelele | + 40mm, 一0mm |

Ⅲ.Litekanyo, libopeho le liphapang tse lumelletsoeng tsa tšepe e cheselitsoeng e nang le sebopeho sa H

Ⅳ.Likarolo tse fapaneng, sebaka se pota-potileng, boima ba maikutlo le likarolo tse fapaneng tsa litšepe tse cheselitsoeng ka sebopeho sa H.

| Lithako tsa tšepe tse se nang tšepe | Boholo | Sectional Area (cm²) | Boima ba 'mele (kg/m) | Likarolo tsa Litšobotsi | Boholo ba fillet ea weld h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25,15 | 1331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1334 | 133 | 5,12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Bareki ba Rona

Maikutlo a tsoang ho bareki ba rona

Lithako tsa Stainless Steel H ke likarolo tsa moralo tse tenyetsehang tse entsoeng ka tšepe ea boleng bo holimo.Likanale tsena li na le sebopeho se ikhethileng sa "H", se fanang ka matla a ntlafetseng le botsitso lits'ebetsong tse fapaneng tsa kaho le tsa meralo. Thepa e boreleli le e bentšitsoeng ea tšepe e sa hloekang e eketsa mokhoa oa ho rarahana, ho etsa hore Beam ena ea H e tšoanelehe bakeng sa likarolo tsa moralo tse sebetsang le tse bonoang. Sebopeho sa sebopeho sa H se eketsa matla a ho jara, ho etsa hore likanale tsena li be tse loketseng bakeng sa ho ts'ehetsa meroalo e boima litsing tsa kaho le tsa indasteri.Stainless Steel H Beams e fumana lits'ebetso liindastering tse fapaneng, ho kenyeletsoa kaho, meaho le tlhahiso, moo ts'ehetso e matla ea meralo e hlokahalang.

Stainless Steel I Beams Packing:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa.Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,