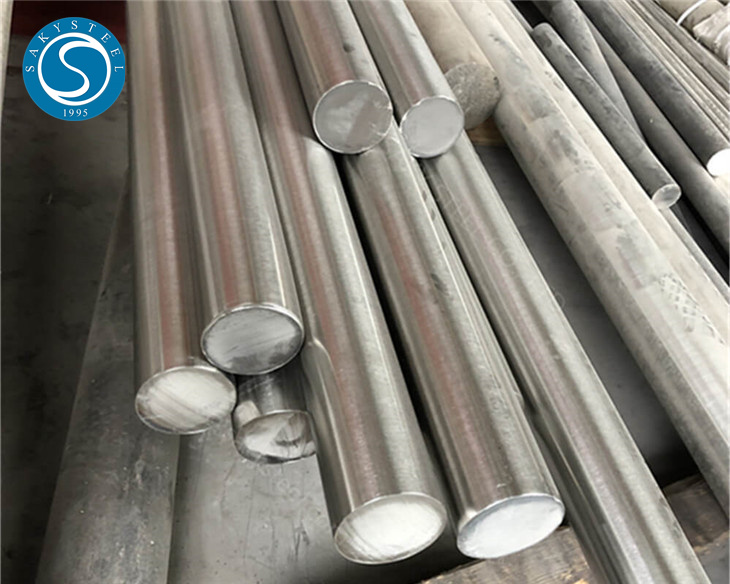

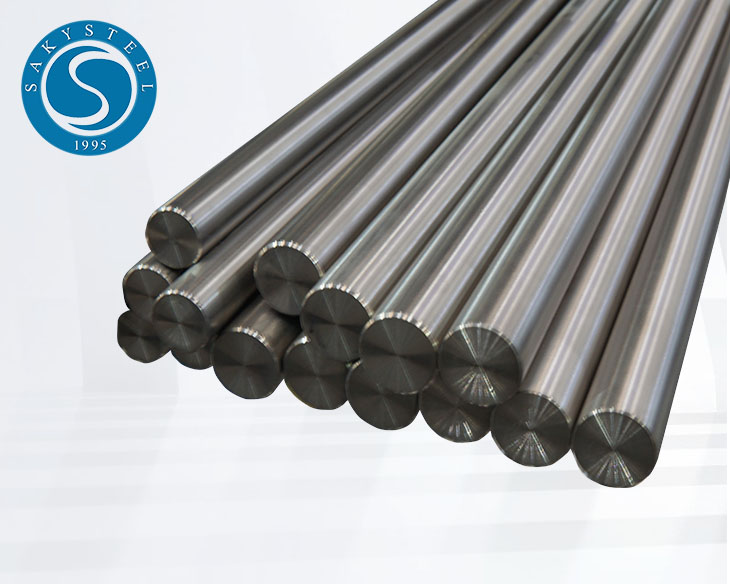

Premium 17-4 PH Stainless Steel Bar for High-Performance Applications

When it comes to high-performance materials, nothing beats the versatility of 17 4 PH stainless steel bar. I know that in industries like aerospace, chemical processing, and oil and gas, durability and strength are non-negotiable. This stainless steel bar, known for its exceptional corrosion resistance and excellent mechanical properties, is a go-to choice for many applications. We’ve got the right sizes and lengths to meet your specific needs, and I often find customers appreciate its ease of fabrication, making it ideal for a variety of projects. Plus, the ability to achieve both high strength and toughness makes it perfect for demanding environments. Our commitment to quality ensures that you get consistent performance with every purchase. Reach out today, and let’s make sure you get exactly what your project needs!

17 4 Ph Stainless Steel Bar Leads the Global Market Your Trusted OEM Partner

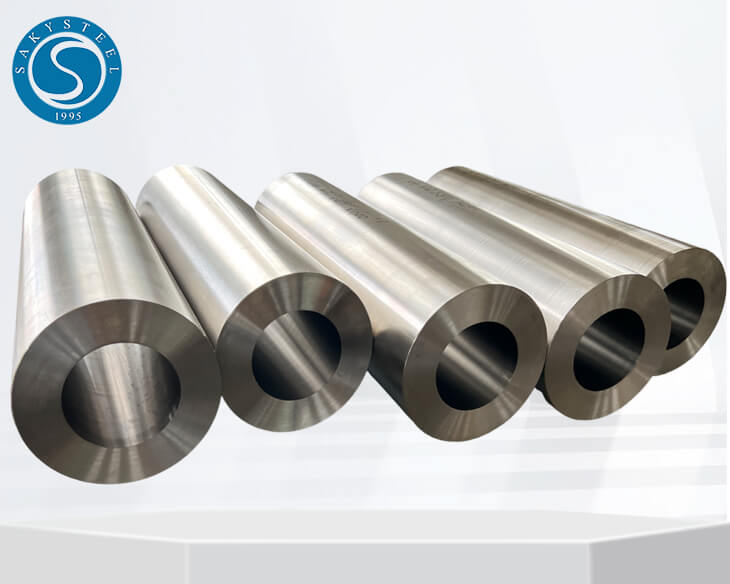

The global stainless steel market is continuously evolving, with 17-4 PH stainless steel bar emerging as a key player due to its exceptional mechanical properties and versatility. This alloy, known for its strength, corrosion resistance, and ease of fabrication, is finding applications across various industries, including aerospace, automotive, and energy. As demand surges, choosing a reliable OEM partner for your sourcing needs becomes essential. A trusted OEM partner can provide tailored solutions that enhance your production processes while ensuring quality consistency. With advanced manufacturing techniques and stringent quality control measures in place, you can rest assured that the 17-4 PH stainless steel bars will meet your specifications and exceed your expectations. Moreover, collaborating with a reputable supplier allows access to a robust supply chain, ensuring timely deliveries and competitive pricing. In today's fast-paced market, making an informed decision about your material suppliers can significantly impact your project's success. By opting for a proven leader in the 17-4 PH stainless steel sector, you not only benefit from superior products but also gain a strategic ally committed to your growth and excellence in execution. Embrace the opportunity to strengthen your operations with quality materials from a dedicated partner.

17 4 Ph Stainless Steel Bar Leads the Global Market Your Trusted OEM Partner

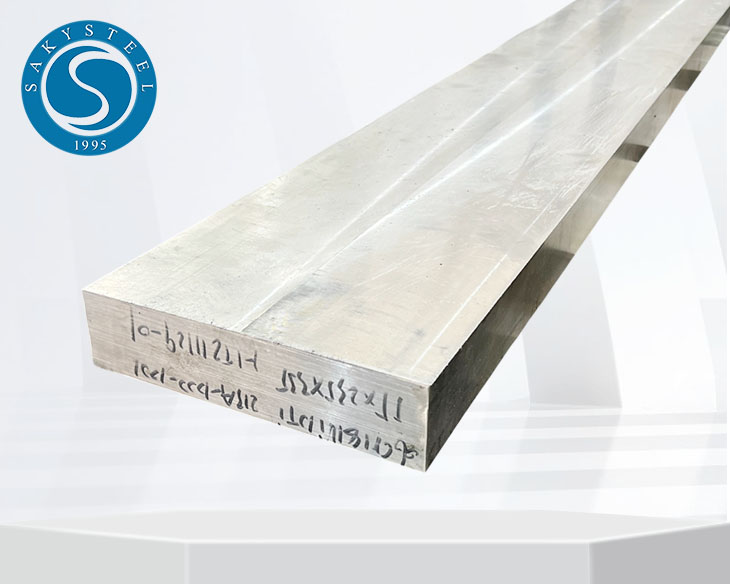

| Dimension (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Applications |

|---|---|---|---|---|---|

| 10 x 10 | 800 | 550 | 20 | 180 | Aerospace, Medical |

| 15 x 15 | 850 | 600 | 25 | 190 | Automotive, Marine |

| 20 x 20 | 900 | 650 | 22 | 200 | Industrial Equipment, Oil & Gas |

| 25 x 25 | 950 | 700 | 21 | 205 | Structural Components, Chemical Processing |

Related Products