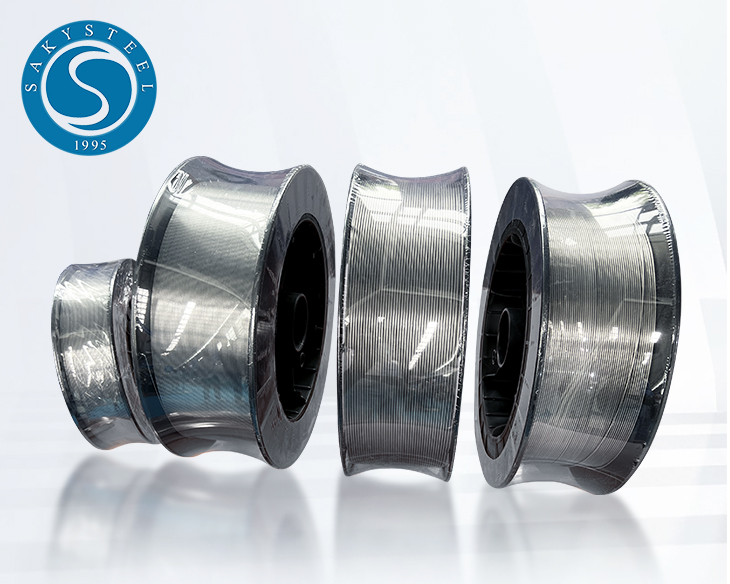

Top 17 4 Welding Wire for Reliable Performance and Quality Results

When I need a reliable solution for tough welding tasks, I always turn to 17 4 Welding Wire. This wire is specifically designed for stainless steel applications, providing excellent corrosion resistance and strength. I often find that projects demanding precision and durability benefit greatly from its exceptional mechanical properties. Feature wise, it’s perfect for fabricators needing a versatile product that gets the job done right, whether in construction or manufacturing. I appreciate how easy it is to work with, and its compatibility with various welding processes makes my job simpler. Customers I’ve talked to, like those in aerospace and automotive industries, value the consistency and quality too. They all mention how the wire minimizes defects and increases productivity, saving both time and costs. If you’re serious about enhancing your welding projects, consider this 17 4 Welding Wire. It’s truly a game-changer for professionals in the field!

17 4 Welding Wire Application Global Reach

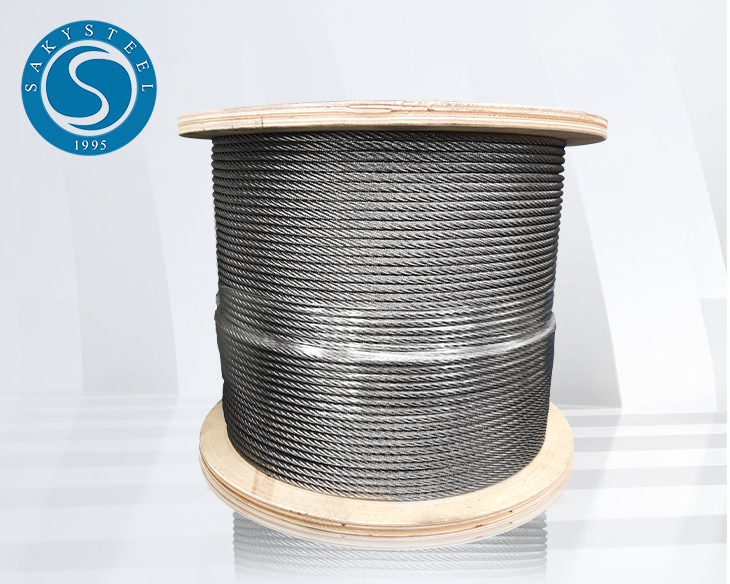

Welding wire is essential in various industrial applications, driving the need for high-quality and reliable products across the globe. As industries rapidly evolve, the demand for welding wire is increasing, particularly in sectors such as construction, automotive, and manufacturing. The application of welding wire is diverse, ranging from structural steel works to delicate pipe welding, which highlights the necessity for suppliers to provide versatile solutions that meet international standards. In today's interconnected world, global reach has become a pivotal factor for procurement teams seeking dependable welding solutions. Suppliers must not only ensure compliance with local regulations but also maintain consistency in quality and performance across diverse markets. This calls for an in-depth understanding of various welding techniques, materials, and customer requirements worldwide. By tailoring products to the specific needs of different regions, businesses can foster strong partnerships and drive innovation, ultimately enhancing productivity and efficiency. The integration of advanced technologies and innovative practices in the production of welding wire further supports its widespread application. With a focus on sustainability and eco-friendly processes, suppliers can meet the rising demand for responsible manufacturing. This forward-thinking approach resonates well with global purchasers looking for reliable partners who prioritize quality, compliance, and environmental stewardship in their supply chains. As the industry evolves, keeping pace with these changes is essential for businesses aiming to thrive in the competitive landscape of welding supplies.

17 4 Welding Wire Application Global Reach

| Region | Application Area | Industry | Welding Process | Key Features |

|---|---|---|---|---|

| North America | Aerospace | Aerospace Manufacturing | TIG Welding | High Strength, Corrosion Resistance |

| Europe | Oil & Gas | Pipeline Construction | MIG Welding | Heat Resistance, High Toughness |

| Asia | Marine | Shipbuilding | Submerged Arc Welding | Durability, Stress Resistance |

| South America | Construction | Building Infrastructure | Flux Core Welding | Flexibility, Ease of Use |

| Africa | Manufacturing | Heavy Machinery | TIG and MIG Combination | Versatility, Weld Quality |

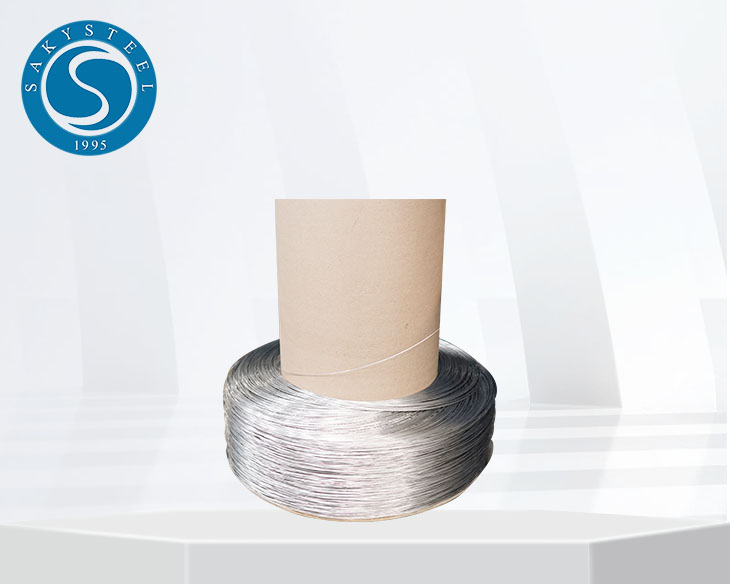

Related Products