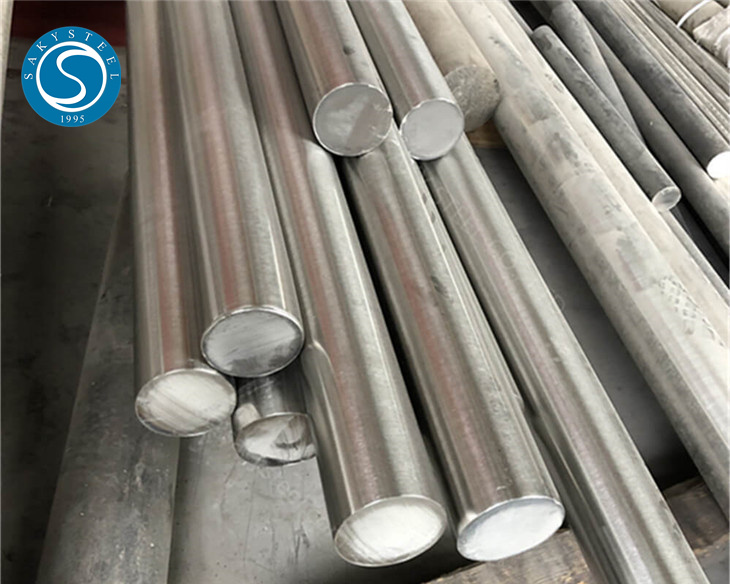

Premium 304 Stainless Bar for Durable Construction & Industrial Use

When you’re in need of high-quality materials, I find that 304 stainless bar is the perfect choice for countless applications. With its excellent corrosion resistance and durability, it’s great for everything from food processing to construction projects. I often recommend this versatile bar because it’s easy to machine and fabricates well, making it ideal for custom parts that need to withstand tough conditions. As a B2B purchaser, you’ll appreciate the reliability and consistency of 304 stainless bar, which ensures your projects run smoothly. Plus, sourcing this material from a trusted supplier can save you time and costs in the long run. Whether you’re working on a large-scale manufacturing operation or a smaller specialized task, this stainless steel bar provides the quality assurance you need. Let's work together to elevate your projects with the dependability of 304 stainless bar; I’m confident you won't be disappointed!

304 Stainless Bar Application Leads the Global Market

In the competitive world of industrial materials, 304 stainless steel bars have emerged as a cornerstone for numerous applications across various sectors. Known for their exceptional corrosion resistance and excellent formability, these stainless steel bars are widely utilized in construction, automotive, food processing, and pharmaceutical industries. Their remarkable properties make them ideal not only for structural components but also for the production of intricate parts requiring high durability and longevity. Global demand for 304 stainless steel bars continues to grow, driven by an increasing focus on quality and reliability in manufacturing processes. As industries evolve, the need for materials that can withstand challenging environments without compromising performance is paramount. This trend is particularly evident in emerging markets, where infrastructure development and industrialization are on the rise. Companies involved in the production and distribution of 304 stainless steel bars are well-positioned to capitalize on this momentum, offering products that meet international standards and cater to the specific needs of diverse applications. For purchasers looking for reliable suppliers, understanding the importance of sourcing high-quality materials is crucial. When choosing a supplier, factors such as traceability, certification, and manufacturing capabilities should be meticulously evaluated. Leveraging advanced technologies and stringent quality control processes ensures that the final products not only comply with regulatory requirements but also exceed customer expectations. In this dynamic landscape, organizations that prioritize innovation and sustainability will lead the market, offering value-added solutions that enhance operational efficiency and drive competitive advantage.

304 Stainless Bar Application Leads the Global Market

| Application Area | Market Share (%) | Growth Rate (%) | Key Properties |

|---|---|---|---|

| Construction | 30 | 5 | Corrosion resistance, high strength |

| Automotive | 25 | 4.5 | Durability, aesthetic appeal |

| Aerospace | 20 | 6 | Lightweight, heat resistance |

| Food Processing | 15 | 3.5 | Hygienic, non-reactive |

| Medical Equipment | 10 | 4 | Biocompatibility, sterilizability |

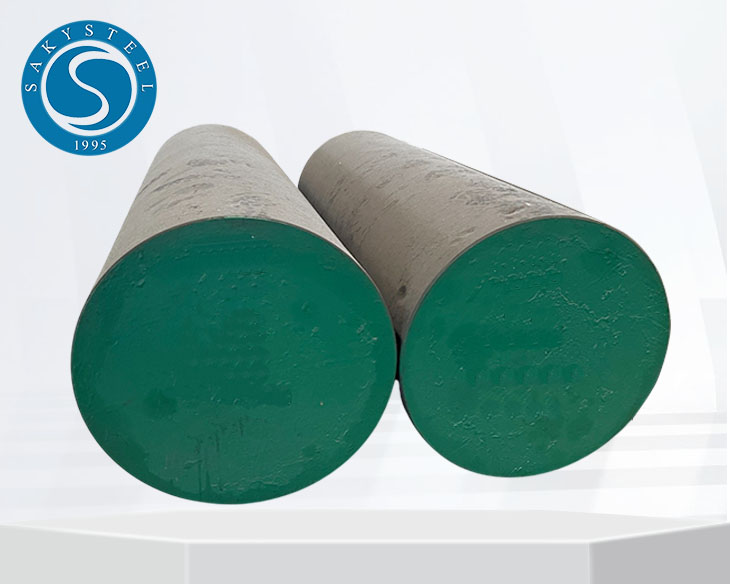

Related Products