308 Stainless Filler Rod: Best Choices for Welding Projects & Applications

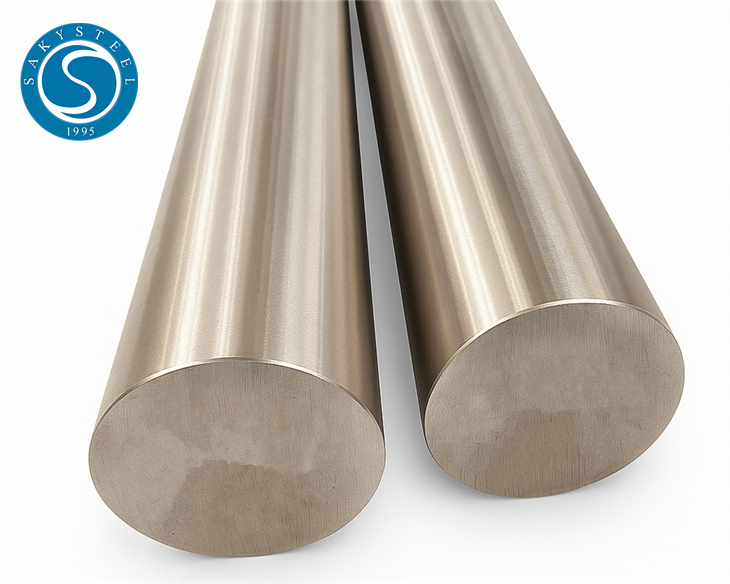

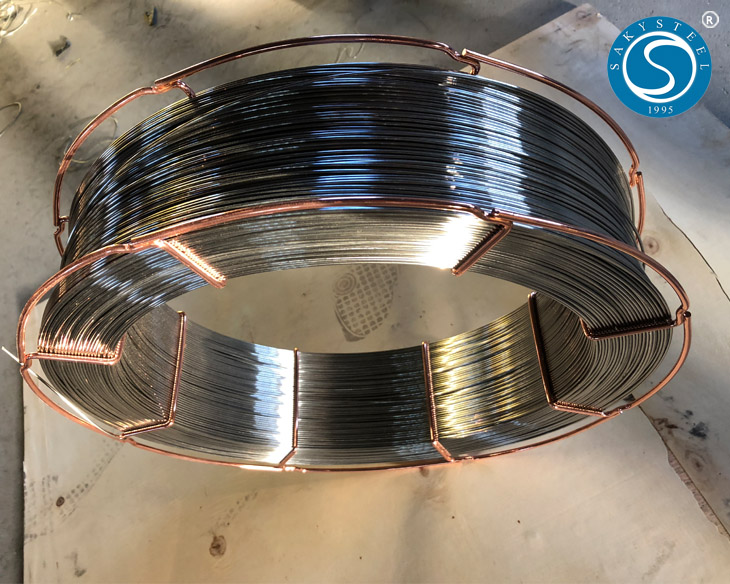

When I need a reliable filler rod for my projects, I always turn to the 308 Stainless Filler Rod. It’s designed specifically for welding austenitic stainless steels, making it perfect for both industrial and commercial applications. I often find it delivers excellent results, providing strong, durable joints that can withstand high temperatures and corrosion. With its smooth arc and minimal spatter, I can easily achieve clean and precise welds every time. I appreciate how it’s compatible with various welding techniques, which makes it versatile for different tasks. Plus, I feel confident recommending it to my team, knowing it meets the high standards our clients expect. If you're searching for quality and performance in your welding projects, the 308 Stainless Filler Rod is truly a solid choice that won't disappoint.

308 Stainless Filler Rod Trusted by Pros Sets the Industry Standard

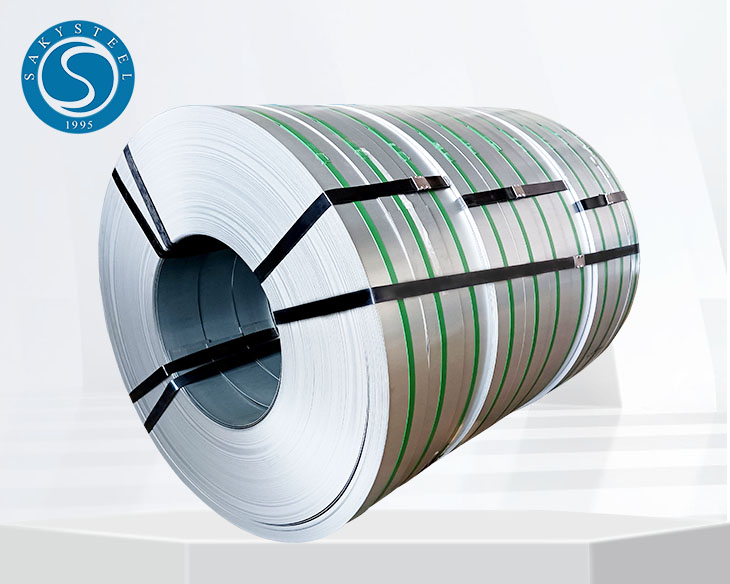

In the world of welding and fabrication, the choice of filler material can significantly impact the quality and durability of the finished product. Among the variety of options available, the 308 stainless filler rod has earned a reputation as a trusted solution favored by professionals across the industry. Known for its corrosion resistance and excellent weldability, this filler rod is particularly suited for welding austenitic stainless steels, making it a top choice for many applications ranging from food processing to construction. What sets the 308 stainless filler rod apart is its consistent performance in various environments. Whether it’s for structural components, automotive parts, or intricate designs, this filler rod maintains excellent mechanical properties and ensures a smooth finish. Its versatility allows it to be used with different welding methods, making it an indispensable tool for both seasoned welders and newcomers alike. As industries continue to evolve, the demand for high-quality, reliable materials will only increase, solidifying the role of the 308 stainless filler rod as an industry standard. For global buyers seeking quality and assurance, investing in trusted materials like the 308 stainless filler rod is essential. By choosing products that meet the highest standards, procurement professionals can ensure the longevity and reliability of their projects, ultimately contributing to greater overall efficiency and success in their operations. Access to superior welding materials is not just a choice; it’s a necessity in an ever-competitive market.

308 Stainless Filler Rod Trusted by Pros Sets the Industry Standard

| Property | Description |

|---|---|

| Material Type | 308 Stainless Steel |

| Diameter | 1/16 inch (1.6 mm) |

| Length | 36 inches (914 mm) |

| Applications | Welding of stainless steel components, food industry, marine applications |

| Welding Process | TIG (GTAW), MIG (GMAW) |

| Strength | Excellent tensile and yield strength |

| Corrosion Resistance | High resistance to oxidation and corrosion |

| Weight | Approximately 0.5 lbs per rod |

Related Products