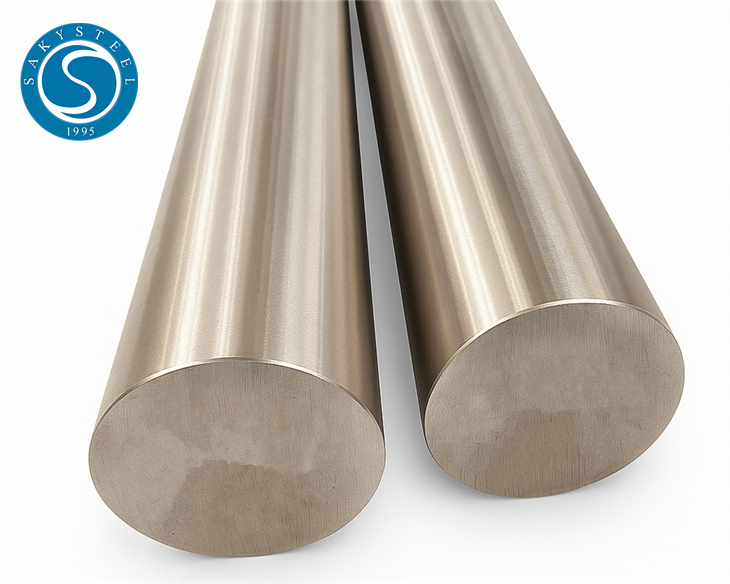

Top Quality 308 Tig Rods for Precision Welding & Durable Performance

When it comes to quality welding, I rely on the 308 Tig Rod for its exceptional performance. This rod is perfect for stainless steel applications, whether you’re working on intricate designs or heavy-duty structures. I find it really showcases my welding skills, providing a smooth finish and impressive strength that keeps my clients coming back. With the increasing demand for reliable welding materials, it’s crucial to have a product that meets high standards. The 308 Tig Rod not only replicates the original materials but also enhances durability. Plus, it's easy to handle, making every project a breeze. If you're seeking a dependable rod that won’t disappoint, this one definitely fits the bill. Don’t miss out on elevating your welding projects. The 308 Tig Rod is an essential investment for anyone wanting to achieve excellence in their welding work. Let’s make your business shine with the right tools!

308 Tig Rod Guarantees Peak Performance Supplies the World\u2019s Top Brands

When it comes to welding materials, the choice of electrode can significantly impact the quality and durability of the welds. The 308 Tig Rod is renowned in the industry for its superior performance and is a preferred choice among professionals worldwide. Offering unmatched corrosion resistance and excellent weldability, this product ensures that every welding project reaches its peak potential. The versatility of the 308 Tig Rod makes it applicable to a wide range of stainless steel grades, which is a vital consideration for international buyers seeking reliable and high-quality welding solutions. In addition to its technical excellence, the 308 Tig Rod provides exceptional ease of use, promoting efficiency on the job site. Its consistent arc stability and minimal spatter contribute to cleaner and stronger welds, reducing the need for extensive post-weld cleanup. This means less downtime and increased productivity, aspects that are crucial for global procurement professionals aiming to optimize their supply chains. With stringent quality control measures and adherence to international standards, procurement agents can trust that the 308 Tig Rod will meet their rigorous requirements. Its ability to deliver peak performance not only satisfies technical demands but also helps in maintaining safety and longevity in all welded structures. As industries continue to evolve, relying on high-performance welding materials like the 308 Tig Rod is essential for those looking to stay ahead in a competitive global market.

308 Tig Rod Guarantees Peak Performance Supplies the World’s Top Brands

| Category | Product Specification | Material Type | Applications | Available Sizes |

|---|---|---|---|---|

| Welding Rods | ER308L | Stainless Steel | Food Processing, Chemical Processing | 1/16", 3/32", 1/8" |

| Welding Rods | ER308LSi | Stainless Steel | Marine Applications, Structural | 3/32", 1/8" |

| Welding Rods | ER308 | Stainless Steel | Automotive, Aerospace | 1/16", 3/32", 1/8" |

| Welding Rods | ER308H | Stainless Steel | High-temperature Applications | 1/16", 1/8" |

| Welding Rods | ER308Ti | Stainless Steel | Corrosion Resistance Applications | 1/16", 3/32", 1/8" |

Related Products