High-Quality 308L Filler Rods for Perfect Welding Results

When I need reliable welding materials, the 308L Filler Rod stands out to me for its versatility and performance. This stainless steel filler rod, perfect for welding Types 304 and 308 base metals, provides excellent corrosion resistance and strength. I’ve found it to be particularly useful in applications involving food processing, chemical plants, and oil refineries. What I appreciate most is its ease of use; whether you're working on thin or thick sections, it delivers a smooth bead with minimal spatter, allowing for a cleaner finish. Plus, I know I’m making a smart investment because it lasts longer, reducing the need for constant replacements. If you're aiming for high-quality welds and reliable results in your projects, this is the ideal choice. Let’s connect to ensure you get the quantities you need at the best prices available.

308l Filler Rod Products Ahead of the Curve

In the ever-evolving landscape of manufacturing and construction, the 308L filler rod stands out for its versatility and superior performance. Designed specifically for applications involving stainless steel welding, this filler rod exhibits excellent corrosion resistance, making it ideal for environments exposed to harsh chemicals and extreme temperatures. By choosing the 308L rod, buyers can ensure a strong and durable bond, which is critical for high-stakes projects that require reliability and longevity. What sets the 308L filler rod apart from other materials is its low carbon content, which minimizes the risk of carbide precipitation during welding. This feature enhances its overall weld integrity, ensuring that the joints maintain their strength even after exposure to various stresses. Furthermore, the rod is compatible with a wide range of welding techniques, allowing companies to streamline their operations and reduce costs. As industries worldwide increasingly prioritize efficiency and quality, having the right materials, like the 308L filler rod, becomes essential to staying ahead of the competition. For global buyers, sourcing high-quality 308L filler rods is not just about meeting technical specifications; it's also about partnering with suppliers who understand the nuances of different applications. By investing in premium-grade filler rods, businesses can optimize their welding processes and deliver superior products to their customers. As the demand for durable and reliable materials continues to grow, the 308L filler rod represents a forward-thinking choice for procurement leaders aiming to enhance their offerings and ensure project success.

308L Filler Rod Products Ahead of the Curve

| Product Name | Diameter (mm) | Length (mm) | Material Composition | Application |

|---|---|---|---|---|

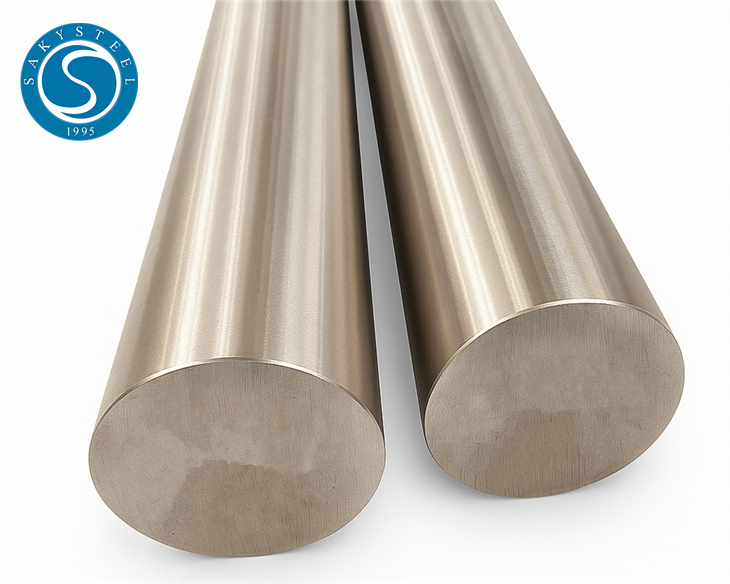

| 308L Stainless Steel Filler Rod | 1.6 | 1000 | 18% Cr, 8% Ni | Welding of Low Carbon Steel |

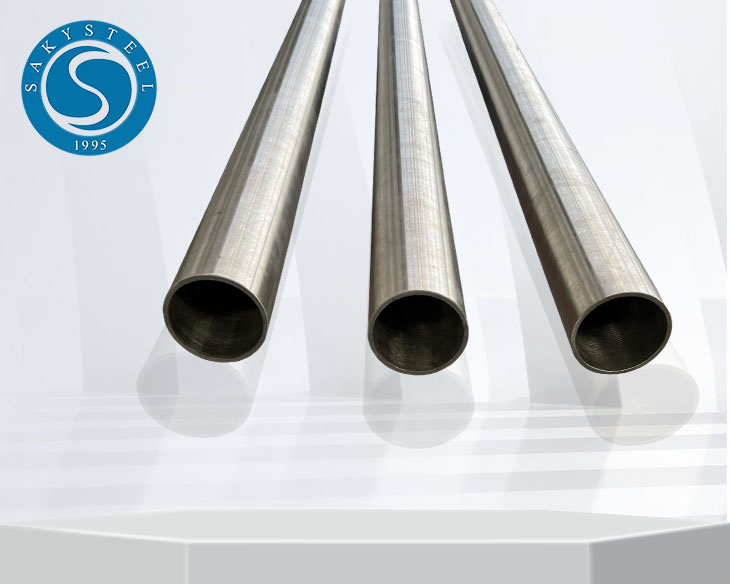

| 308L TIG Welding Rod | 2.4 | 1500 | 18% Cr, 8% Ni, 0.03% C | Stainless Steel Fabrication |

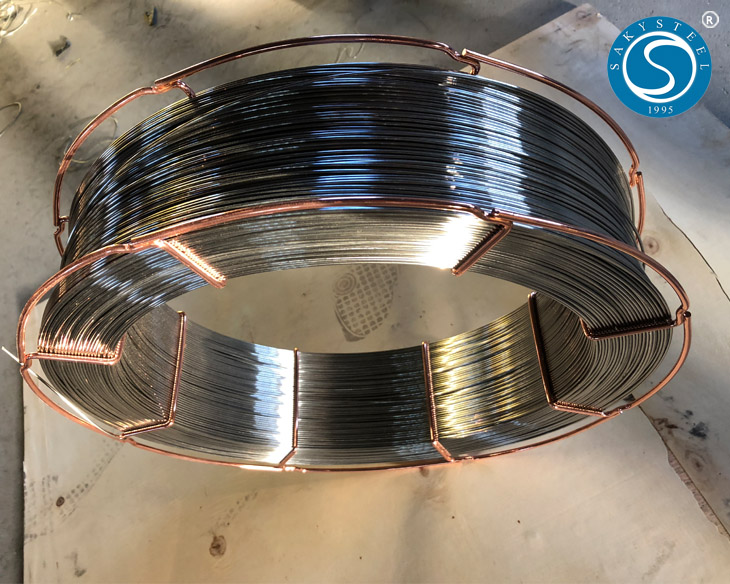

| 308L MIG Welding Wire | 0.8 | 5000 | 18% Cr, 8% Ni | General Purpose Welding |

| 308L Flux-Cored Wire | 1.2 | 1000 | 18% Cr, 8% Ni, 0.03% C | Heavy Fabrication |

Related Products