316L Stainless Steel Wire: Quality Options for Industrial Applications

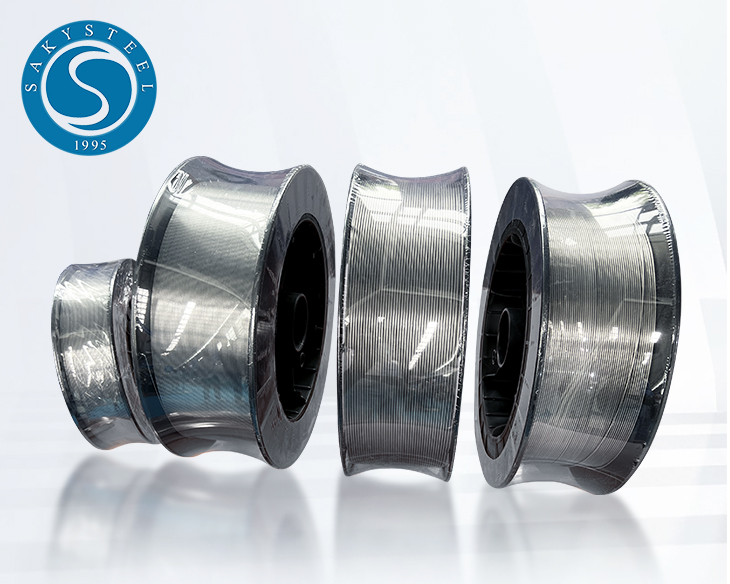

When I talk about durability and corrosion resistance, 316L stainless steel wire tops the list. This wire is perfect for various applications, from marine environments to medical devices, where quality is non-negotiable. I appreciate how its low carbon content minimizes the risk of carbide precipitation, ensuring longevity and stability under extreme conditions. Understanding the importance of reliability, I've seen firsthand how this wire stands up against harsh elements, making it an excellent choice for manufacturers like you. Whether you're in aerospace, automotive, or construction, 316L stainless steel wire can enhance your products' overall performance. Choosing the right supplier matters. I ensure consistent quality and timely deliveries, tailored to your specific needs. Don’t compromise on your projects—partner with me for your stainless steel wire needs. Together, we can ensure your success and exceed your customers' expectations. Let's create exceptional solutions together!

316l Stainless Steel Wire Factory Custom Solutions,

When sourcing materials for industrial applications, the choice of wire can significantly impact the quality and durability of your products. 316L stainless steel wire is a go-to option for many industries due to its excellent corrosion resistance, high tensile strength, and versatility. Our custom solutions cater specifically to the unique needs of global buyers, whether you require specific diameters, lengths, or finishes. By leveraging advanced manufacturing processes and stringent quality control measures, we ensure that every coil of 316L stainless steel wire meets the highest standards. Our production capabilities allow for tailored solutions, accommodating everything from small-scale orders to large production runs. Furthermore, our knowledgeable team is dedicated to working closely with clients to understand their requirements and provide expert guidance on the best applications of our wire products. With a commitment to excellence and customer satisfaction, our 316L stainless steel wire is perfect for a wide range of applications, including marine environments, chemical processing, and food production. Trust in our expertise and quality to elevate your operations and ensure the longevity and reliability of your products.

316L Stainless Steel Wire Custom Solutions

| Application | Diameter Range (mm) | Finish Options | Certifications | Customization Availability |

|---|---|---|---|---|

| Automotive | 0.5 - 5.0 | Bright, Annealed | ISO 9001 | Yes |

| Medical Devices | 0.2 - 3.0 | Polished, Passivated | ASTM F138 | Yes |

| Aerospace | 0.3 - 4.0 | Unpolished, Cold Drawn | AMS 5639 | Yes |

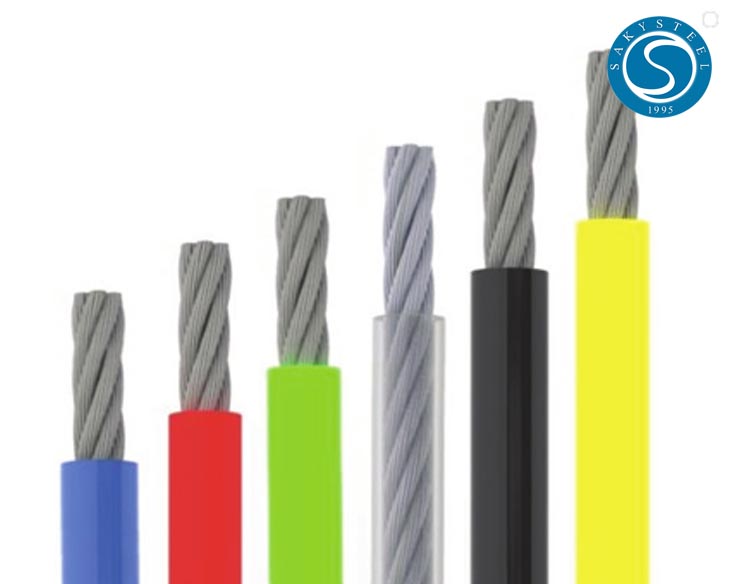

| Construction | 1.0 - 8.0 | Galvanized, PVC Coated | BS EN ISO 3834 | Yes |

| Electrical | 0.1 - 2.5 | Tinned, Nickel Plated | IEC 60068 | Yes |

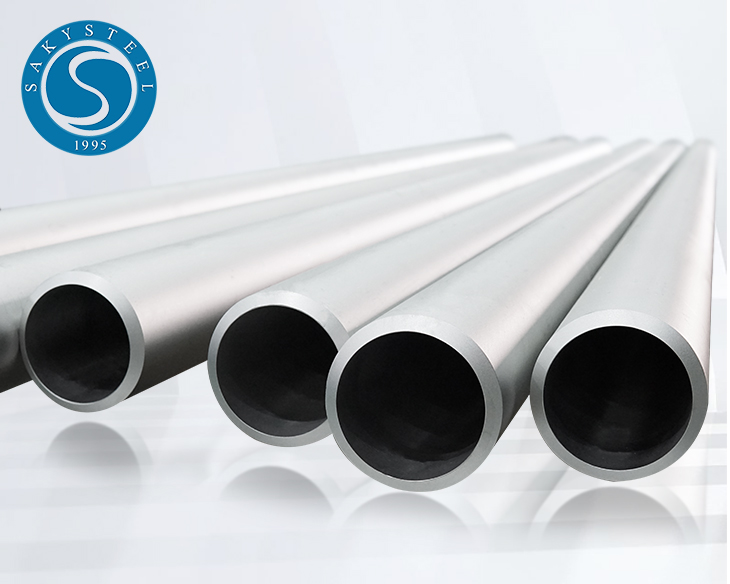

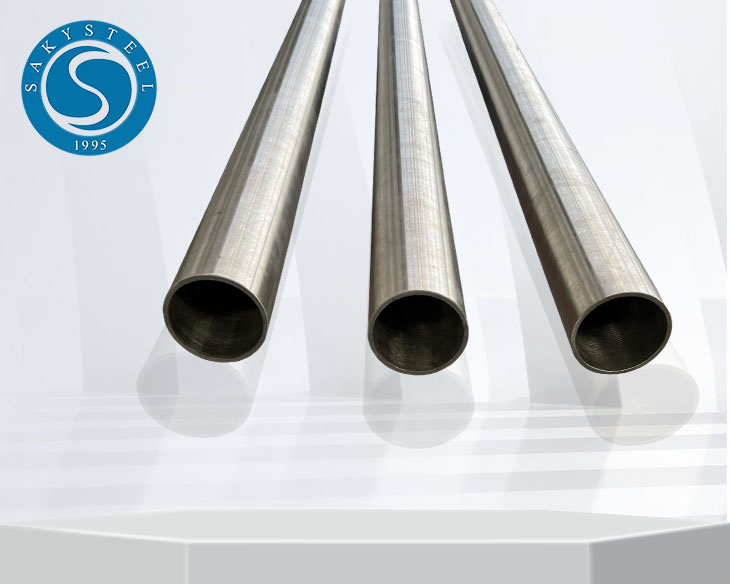

Related Products