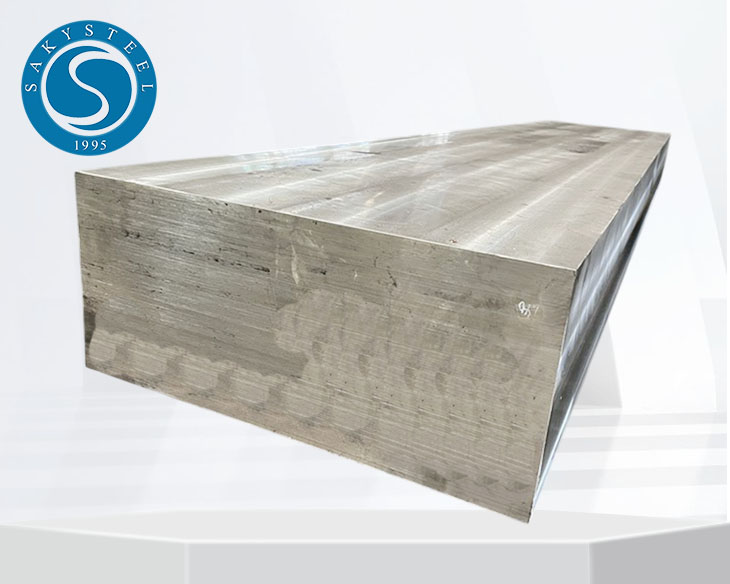

H13 Tool Steel: High-Performance Options for Precision Applications

When it comes to high-performance applications, H13 Tool Steel stands out for its exceptional toughness and heat resistance. I often recommend it for industries needing reliability under extreme conditions, especially in die casting and forging. This tool steel can withstand high temperatures without losing its strength, making it a go-to choice for manufacturers looking to boost their productivity. With its excellent wear resistance, I find that H13 is perfect for heavy-duty tooling applications where longevity is crucial. Many of my clients appreciate the ease of machining it offers, allowing for precise designs that meet their strict quality standards. For those ready to invest in top-tier materials, H13 Tool Steel is a solid choice that can enhance operational efficiency. If you want a material that excels in demanding environments, let’s discuss how H13 can meet your needs!

H13 Tool Steel Supplier Supplies the World\u2019s Top Brands

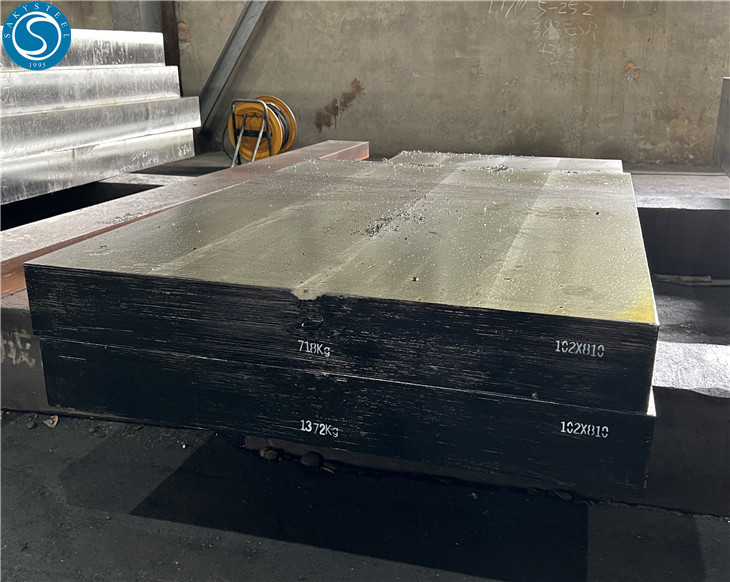

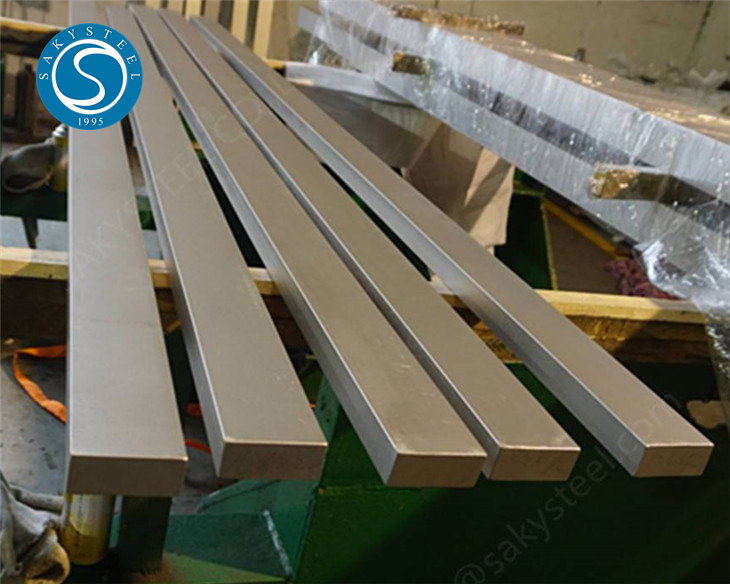

In today's competitive landscape, the demand for high-quality materials is ever-increasing, particularly in the tool manufacturing sector. H13 tool steel, renowned for its exceptional toughness and heat resistance, stands out as a preferred choice for many top brands in various industries, including automotive, aerospace, and manufacturing. This versatile steel is not only efficient in maintaining its integrity under high temperatures but also offers excellent wear resistance, making it ideal for production processes that require high durability and performance. As a trusted supplier of H13 tool steel, we understand the intricate needs of global buyers. Our commitment to providing superior quality products ensures that our clients can rely on us for their most demanding projects. We prioritize development and innovation, continuously enhancing our manufacturing processes to meet the evolving standards of industries worldwide. By partnering with us, procurement professionals will gain access to a stable supply of H13 tool steel, effectively supporting their production timelines and operational efficiency. Moreover, our extensive quality assurance measures guarantee that every batch of H13 tool steel adheres to international specifications, allowing our clients to maintain their reputation for excellence. By choosing a supplier who prioritizes quality and customer satisfaction, global buyers can confidently craft their products with the assurance that they are utilizing one of the best materials available on the market. Together, let’s forge a path towards a more prosperous and productive future.

H13 Tool Steel Supplier Supplies the World’s Top Brands

| Product Type | Brand | Application Area | Heat Treatment Process | Country of Origin |

|---|---|---|---|---|

| H13 Tool Steel | Brand A | Die Casting | Quenching and Tempering | USA |

| H13 Tool Steel | Brand B | Forging Molds | Air Hardening | Germany |

| H13 Tool Steel | Brand C | Injection Molding | Oil Quenching | Japan |

| H13 Tool Steel | Brand D | Hot Work Applications | Induction Hardening | China |

| H13 Tool Steel | Brand E | Stamping Dies | High-Temperature Tempering | Italy |

Related Products