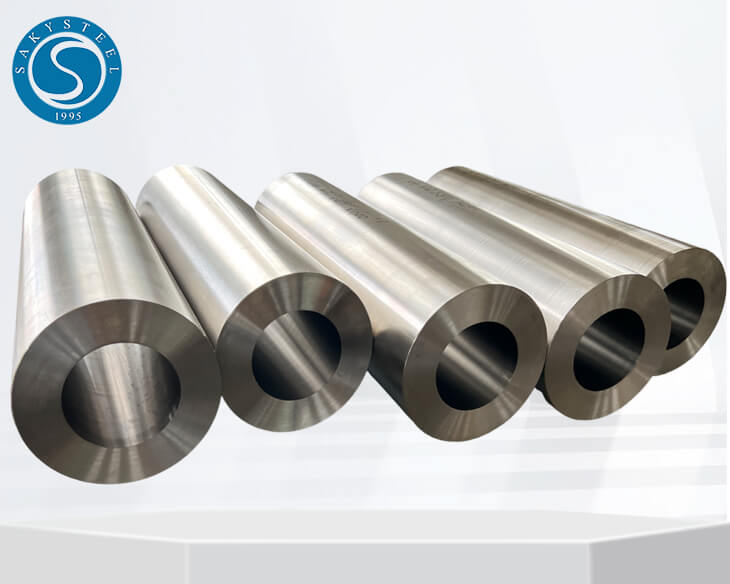

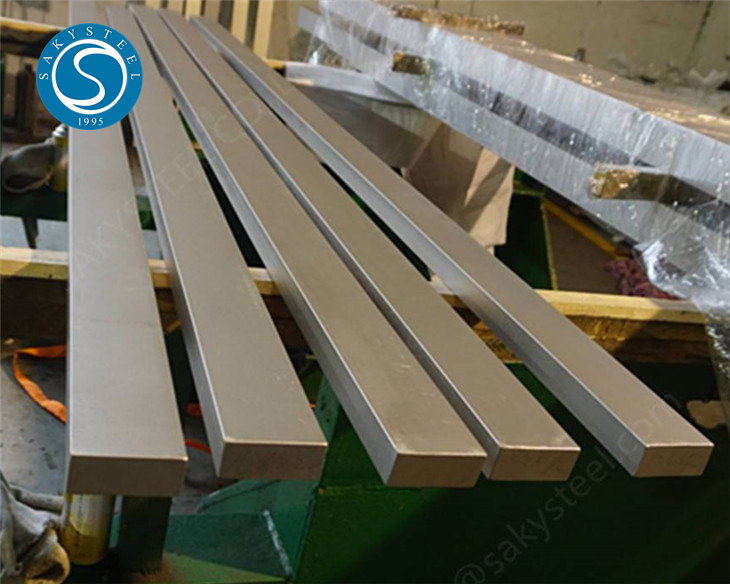

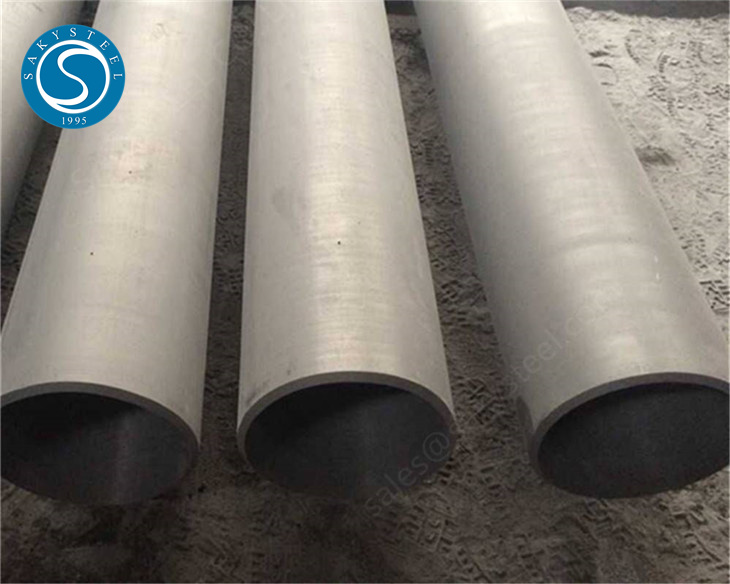

High-Quality Stainless Steel Hollow Bar for Industrial Applications

When it comes to finding the right stainless steel hollow bar, I know how crucial it is for projects that require both strength and durability. Our hollow bars are crafted from high-quality stainless steel, ensuring they withstand corrosion and extreme environments, making them perfect for various applications, from structural supports to automotive parts. I can assure you that these products come in a range of sizes and specifications, tailored to meet your unique requirements. I’ve seen firsthand how our clients appreciate the precision and reliability that our materials deliver, allowing them to complete their projects on time. If you're after competitive pricing and prompt delivery, you’ve come to the right place. Let me help you streamline your procurement process, ensuring you get the best value for your investment. Reach out today, and let’s discuss how we can meet your stainless steel hollow bar needs effectively!

Stainless Steel Hollow Bar Delivers Unmatched Quality Where Innovation Meets 2025

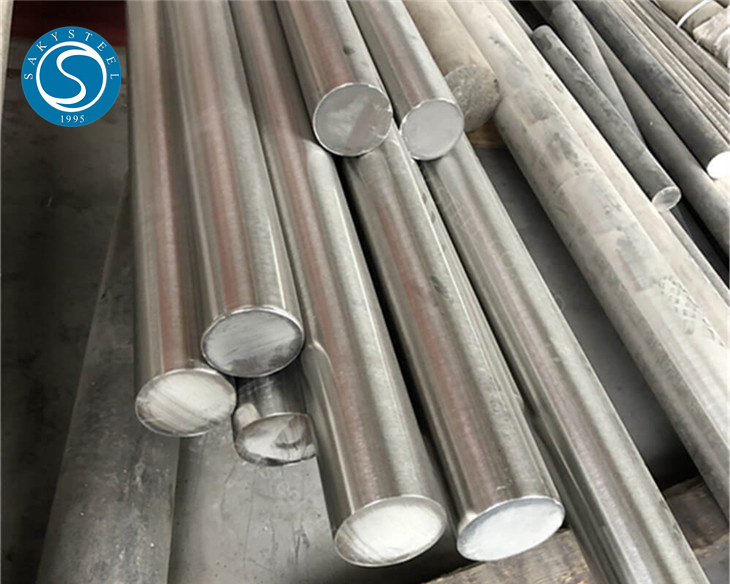

The evolution of the stainless steel hollow bar in industrial applications is an exciting topic as we approach 2025. Stainless steel hollow bars are increasingly becoming the material of choice due to their unique properties such as high corrosion resistance, lightweight strength, and versatility. These attributes make them ideal for a variety of industries including aerospace, automotive, and construction, where durability and performance are non-negotiable. As we embrace innovation in manufacturing processes, the quality of stainless steel hollow bars continues to improve. Advanced production techniques enhance their structural integrity, ensuring that they meet the rigorous demands of modern applications. Additionally, continuous material research leads to the development of new stainless steel alloy compositions that can provide even greater reliability and performance in extreme environments. For global buyers, understanding the advantages and applications of stainless steel hollow bars is crucial. As the industry moves towards a more sustainable future, investing in these high-quality materials not only secures superior performance but also aligns with environmental goals by reducing waste and extending the lifecycle of products. Embracing this innovation will undoubtedly position businesses for success in the dynamic landscape of 2025 and beyond.

Stainless Steel Hollow Bar Delivers Unmatched Quality Where Innovation Meets 2025

| Dimension (mm) | Weight (kg/m) | Material Grade | Corrosion Resistance | Certification |

|---|---|---|---|---|

| 25 x 20 | 2.5 | 304 | Excellent | ISO 9001 |

| 30 x 25 | 3.0 | 316 | Very Good | ASTM |

| 40 x 30 | 4.0 | 2205 | Good | EN 10204 |

| 50 x 40 | 5.2 | Duplex | Excellent | NACE MR0175 |

| 60 x 50 | 6.8 | 310 | Excellent | ASME |

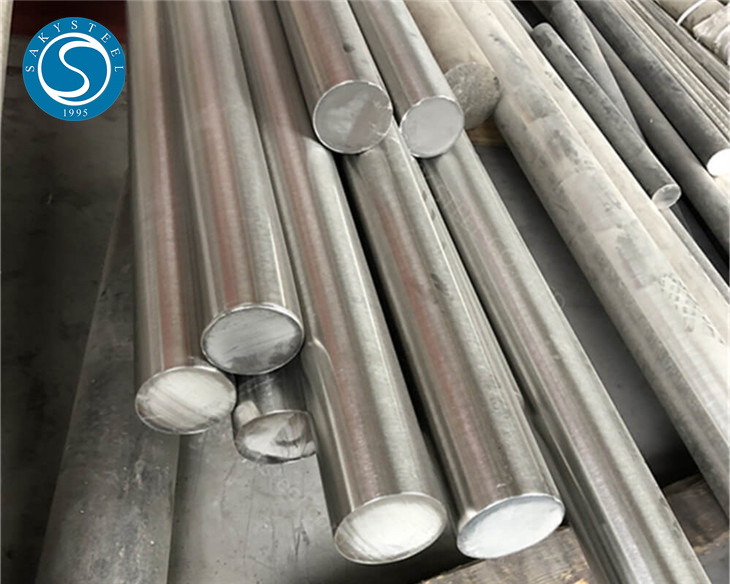

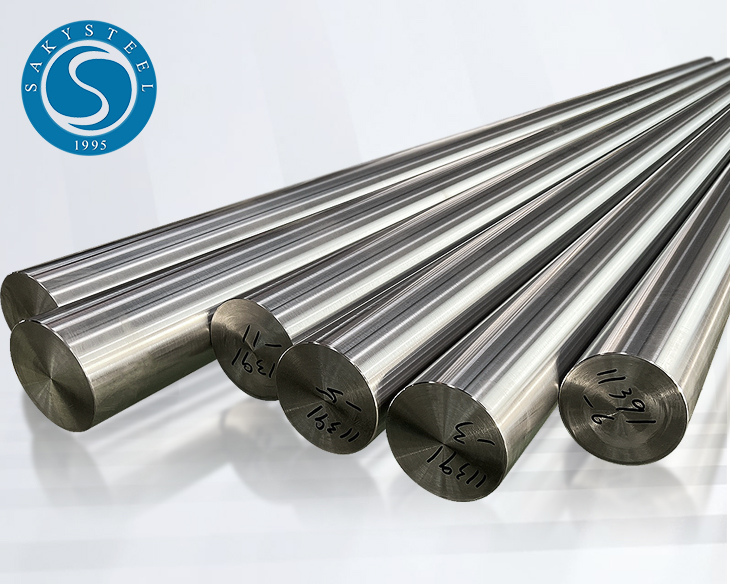

Related Products