2205 Welding Wire: Durable Solutions for Your Welding Projects

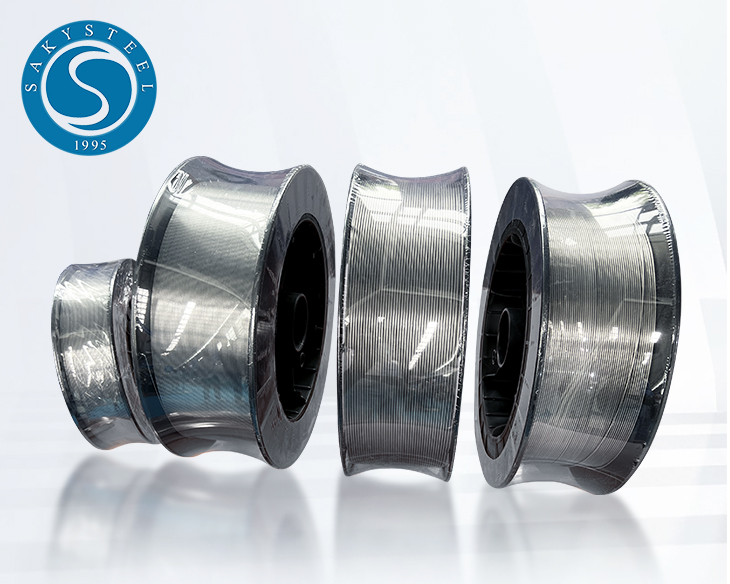

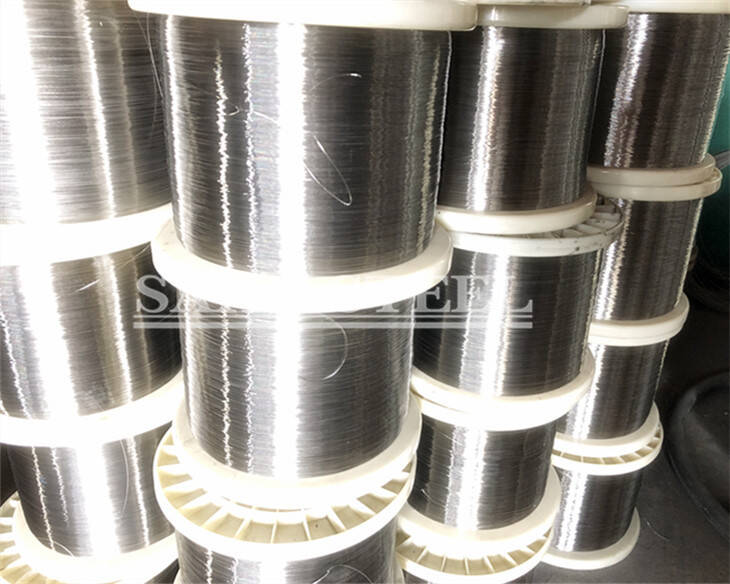

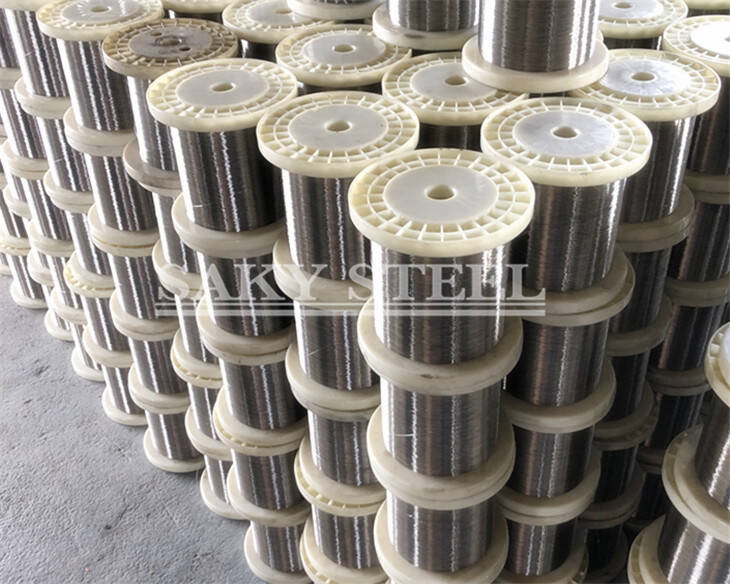

When I use the 2205 Welding Wire, I know I'm getting a product that's built for performance and reliability. This wire is perfect for duplex stainless steel applications, providing excellent corrosion resistance and superb weld quality. Buyers like you will appreciate its versatility, whether you're in the oil and gas industry or working on marine projects. I take pride in offering a welding solution that ensures strong joints and minimizes the risk of post-weld cracking. With its high strength and durability, it's designed to perform in the toughest environments. Plus, you’ll find it easy to handle, making your job smoother and more efficient. Choosing the right welding wire doesn’t have to be complicated. Let me help you elevate your projects with 2205 Welding Wire that meets industry standards and exceeds expectations. Reach out for more details today!

2205 Welding Wire Factory Trusted by Pros

When it comes to sourcing high-quality welding wire, professionals across industries understand the importance of partnering with a trusted factory. A leading manufacturing expert specializes in producing a wide range of welding wires known for their superior performance and reliability. With state-of-the-art production facilities and a commitment to stringent quality control, every spool of wire that leaves the factory is crafted to meet international standards. The factory prides itself on its extensive experience in the welding sector, delivering products that cater to various applications, from automotive to construction. Their welding wires are designed for easy use and exceptional results, ensuring strong and durable welds that professionals can rely on. Additionally, by embracing innovative technologies and sustainable practices, the factory not only enhances product quality but also reduces environmental impact, aligning with the growing demand for eco-friendly solutions. By choosing a trusted welding wire manufacturer, global buyers can gain a competitive edge. With a focus on customer satisfaction, the factory offers tailored solutions to meet specific project needs, ensuring timely deliveries and responsive support. Whether you are a large-scale manufacturer or a small workshop, aligning with a reputable welding wire supplier can significantly elevate your production capabilities and project outcomes.

2205 Welding Wire Factory Trusted by Pros

| Specification | Wire Diameter (mm) | Material Composition | Applications | Heat Treatment |

|---|---|---|---|---|

| ER2205 | 1.0 | 22% Cr, 5% Ni | Marine, Oil & Gas | Solution Annealing |

| ER2205 | 1.2 | 22% Cr, 5% Ni | Chemical Processing | None Required |

| ER2205 | 1.6 | 22% Cr, 5% Ni | Power Generation | Stress Relief |

| ER2205 | 2.0 | 22% Cr, 5% Ni | Structural Applications | None Required |

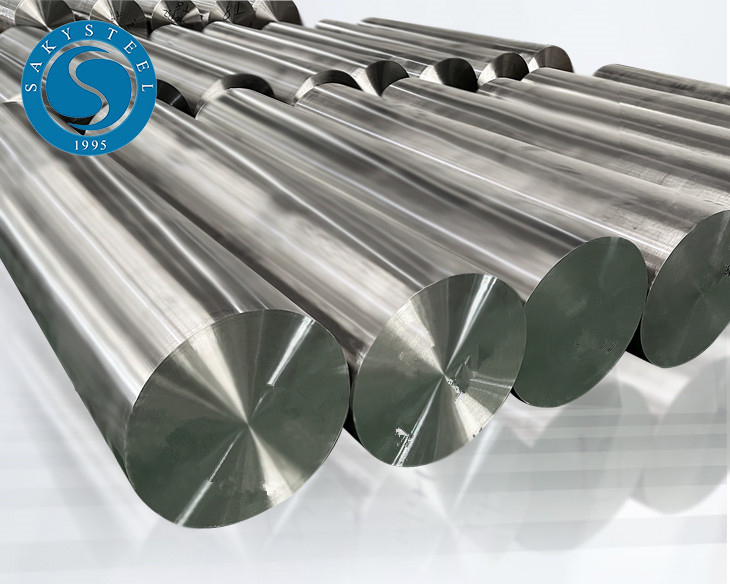

Related Products