309 Wire Welding: Expert Tips for Optimal Performance and Quality Results

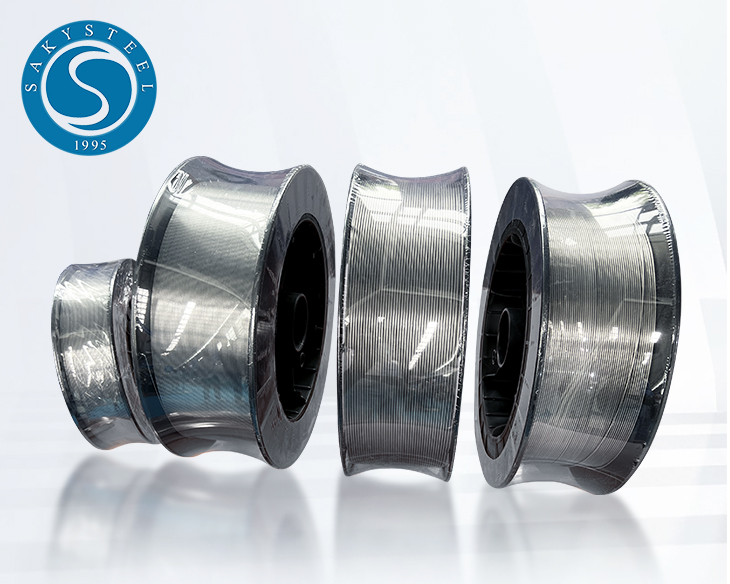

When I needed reliable welding solutions, 309 Wire Welding became my go-to choice. This versatile welding wire is specifically designed for joining dissimilar metals and provides excellent corrosion resistance. Whether you’re dealing with stainless steel or carbon steel, this wire ensures strong, lasting welds. I’ve found that 309 wire not only enhances productivity but also reduces the risk of defects, making it ideal for critical applications in industries like construction and manufacturing. With impressive arc stability, it allows for precise control, giving me confidence in every project. What truly sets this product apart is its ability to handle challenging environments while maintaining exceptional performance. As a B2B buyer, I appreciate the value it brings to my operations. If you’re searching for quality and reliability in your welding processes, you can’t go wrong with 309 Wire Welding. It’s a game-changer that meets the demands of today’s industry.

309 Wire Welding Dominates Winning in 2025

As we look ahead to 2025, the significance of 309 wire welding emerges as a dominant force in diverse industries, particularly in manufacturing and construction. Known for its exceptional strength and durability, 309 wire welding is uniquely suited for high-temperature applications and environments where corrosion resistance is essential. This material’s unique composition allows it to perform optimally even in the most demanding conditions, making it an ideal choice for global procurement managers seeking reliable solutions. With the rapid advancements in technology and innovative manufacturing processes, companies are increasingly turning to 309 wire welding for their projects. Its versatility not only ensures that it meets various industrial standards but also enhances productivity and efficiency. By investing in high-quality materials like 309 wire welding, businesses can significantly reduce downtime and maintenance costs, leading to improved profit margins. As more manufacturers recognize these benefits, the demand for this superior welding wire is expected to surge, positioning it as a cornerstone of success in the competitive industrial landscape of 2025. For procurement specialists, understanding the advantages of 309 wire welding will be paramount. Embracing this trend early on can give companies a competitive edge, facilitating better negotiations with suppliers and optimizing project timelines. As industries adapt to changing market demands, the strategic choice of materials will play a crucial role in driving operational excellence and achieving sustainable growth.

309 Wire Welding Dominates Winning in 2025

| Category | 2023 Usage (MT) | 2024 Projected Usage (MT) | 2025 Projected Usage (MT) | Growth Rate (%) |

|---|---|---|---|---|

| Construction | 1500 | 1800 | 2200 | 22.22 |

| Automotive | 1200 | 1400 | 1600 | 14.29 |

| Aerospace | 800 | 900 | 1100 | 22.22 |

| Shipbuilding | 700 | 800 | 900 | 12.50 |

| Manufacturing | 500 | 600 | 700 | 16.67 |

Related Products