316L Stainless Steel Tubing: Durable Solutions for Your Projects

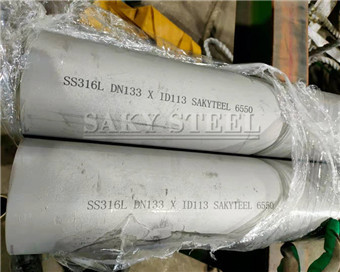

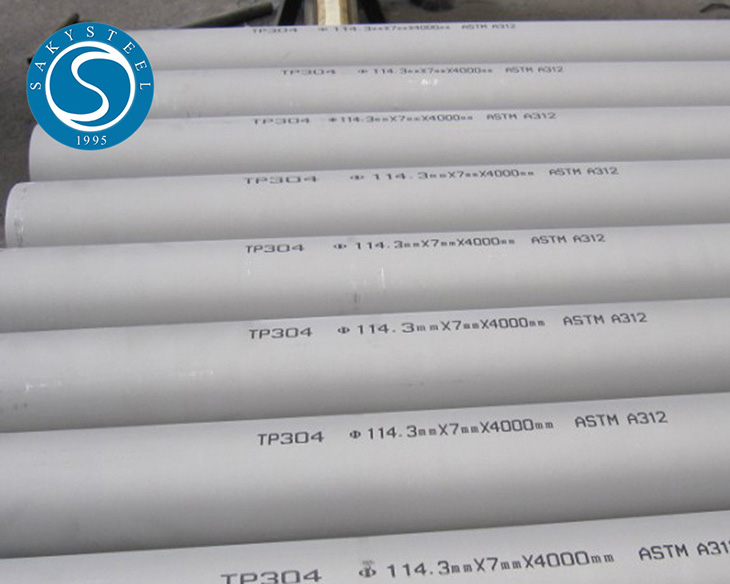

When I think about high-performance materials for our projects, 316L stainless steel tubing always comes to mind. As a B2B purchaser, I understand the importance of durability and corrosion resistance in industrial applications. This particular tubing offers exceptional resistance to pitting and crevice corrosion, making it ideal for harsh environments. Whether I need it for chemical processing, marine applications, or even food production, I can trust its reliability. With its smooth surface finish, 316L stainless steel tubing can easily be welded and fabricated, which is critical for our demanding projects. Our team appreciates the variety of sizes available, allowing us to choose precisely what we need without compromise. Plus, its excellent tensile strength means I can feel confident about the structural integrity of our end products. If you’re like me and prioritizing quality and performance in your procurement decisions, this tubing is an excellent choice to meet industry standards.

316l Stainless Steel Tubing Products Delivers Unmatched Quality

When it comes to high-performance applications, 316L stainless steel tubing stands out as a superior choice for global buyers seeking unmatched quality. Renowned for its exceptional corrosion resistance and durability, 316L tubing is ideal for a range of industries, including chemical processing, marine, and medical applications. This grade of stainless steel maintains its integrity under harsh conditions and high temperatures, ensuring reliability where it matters most. One of the key advantages of 316L stainless steel tubing is its low carbon content, which greatly minimizes the risk of carbide precipitation during welding. This feature makes it particularly appealing for projects requiring high weldability and seamless connections. Furthermore, its ability to withstand aggressive environments—such as chloride exposure—makes it the go-to material for marine and coastal applications, where traditional materials may fail. Investing in 316L stainless steel tubing products translates to long-term cost savings for businesses. The extended lifespan and reduced maintenance requirements of these products can significantly enhance operational efficiency. By choosing high-quality tubing, procurement managers can ensure their projects meet the stringent safety and performance standards expected in today’s competitive marketplace. Thus, for global sourcing professionals, 316L stainless steel tubing is a forward-thinking choice that aligns with both quality and value.

316l Stainless Steel Tubing Products Delivers Unmatched Quality

| Product Type | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Application |

|---|---|---|---|---|

| Seamless Tubing | 25.4 | 1.2 | 6 | Chemical Processing |

| Welded Tubing | 19.05 | 1.0 | 5 | Automotive |

| Instrumentation Tubing | 12.7 | 0.5 | 3 | Oil and Gas |

| Heat Exchanger Tubing | 38.1 | 2.0 | 8 | Power Generation |

| Low-Pressure Tubing | 15.88 | 0.6 | 4 | Food Industry |

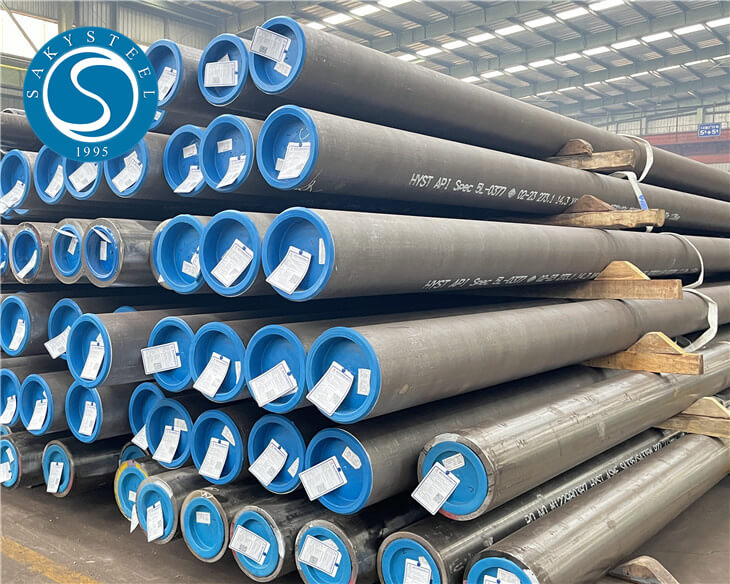

Related Products