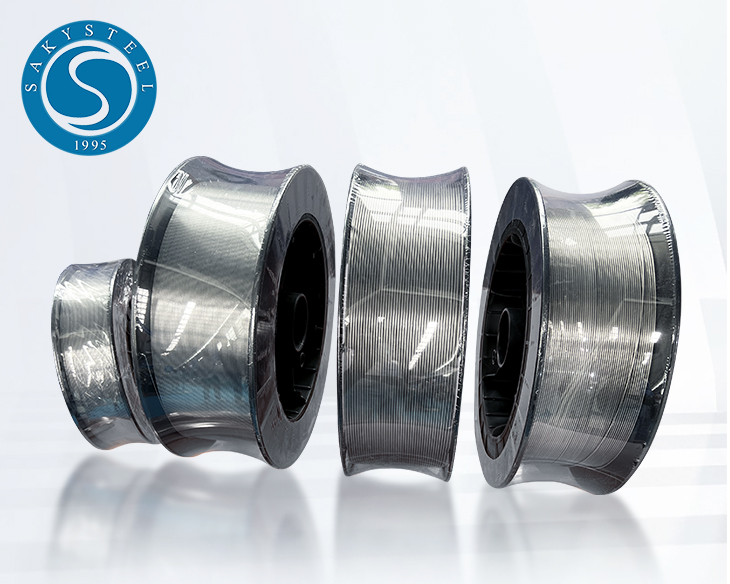

316L Welding Wire - High Performance for Professional Applications

When it comes to reliable and high-quality welding solutions, our 316L welding wire stands out from the rest. As someone who's spent years in the industry, I understand that durability and corrosion resistance are critical for your projects. This wire is perfect for applications in chemical processing, marine environments, and medical devices, making it a solid choice for diverse industries. I really appreciate how this wire not only provides excellent weldability but also offers outstanding mechanical properties, ensuring that your welds are strong and consistent. Plus, it’s designed to reduce spatter and improve cleaning, which saves time and effort during your projects. If you're aiming for top-notch performance and exceptional results, our 316L welding wire will not disappoint. Reach out today to discuss your needs and see how my expertise can support your business goals. Let’s create a partnership that drives success together!

316l Welding Wire Products Delivers Unmatched Quality

When it comes to sourcing high-quality welding materials, the significance of superior 316L welding wire cannot be overstated. This exceptional product is designed for industries that demand reliability and performance in extreme environments. The 316L grade offers enhanced corrosion resistance, making it ideal for applications in marine, chemical, and food processing sectors. Its low carbon content minimizes the risk of carbide precipitation, ensuring that welds remain strong and durable even under aggressive conditions. Our 316L welding wire is produced using advanced manufacturing techniques that adhere to stringent quality standards. This attention to detail ensures consistent performance across all batches, providing peace of mind for global procurement managers looking for dependable solutions. Whether you are completing a critical project or seeking essential materials for ongoing operations, our welding wire guarantees unmatched quality that meets industry demands. Investing in high-grade welding materials like 316L welding wire not only enhances the quality of your projects but also contributes to long-term savings by reducing the likelihood of costly repairs and replacements. By choosing reliable materials, businesses can ensure the structural integrity and longevity of their constructions, ultimately driving success in today’s competitive market.

316L Welding Wire Products Delivers Unmatched Quality

| Product Type | Diameter (mm) | Material Composition | Welding Technique | Applications |

|---|---|---|---|---|

| 316L Wire | 0.8 | Fe, Ni, Cr, Mo | MIG | Food Processing, Chemical Industries |

| 316L Wire | 1.0 | Fe, Ni, Cr, Mo | TIG | Marine Applications, Oil & Gas |

| 316L Wire | 1.2 | Fe, Ni, Cr, Mo | Submerged Arc | Power Generation, Heavy Industry |

| 316L Wire | 1.6 | Fe, Ni, Cr, Mo | MIG | Pharmaceutical, Biotechnology |

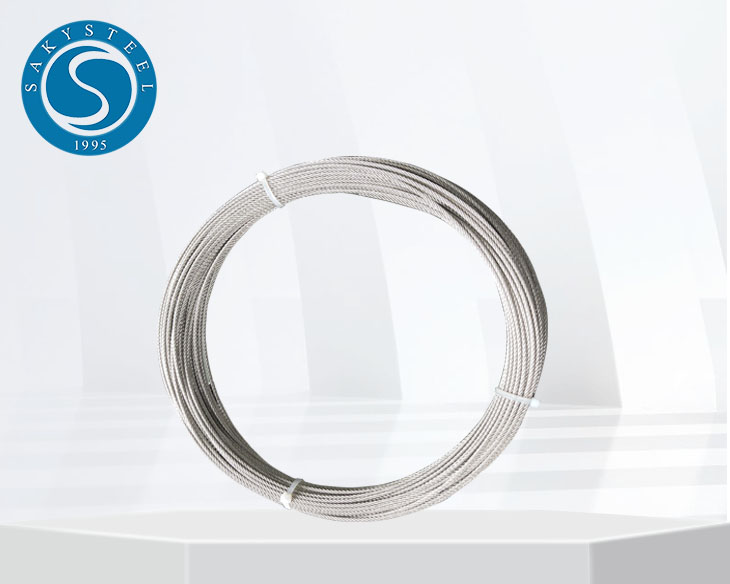

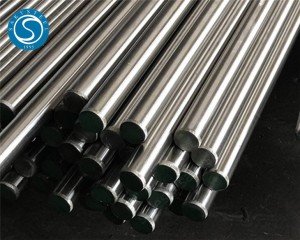

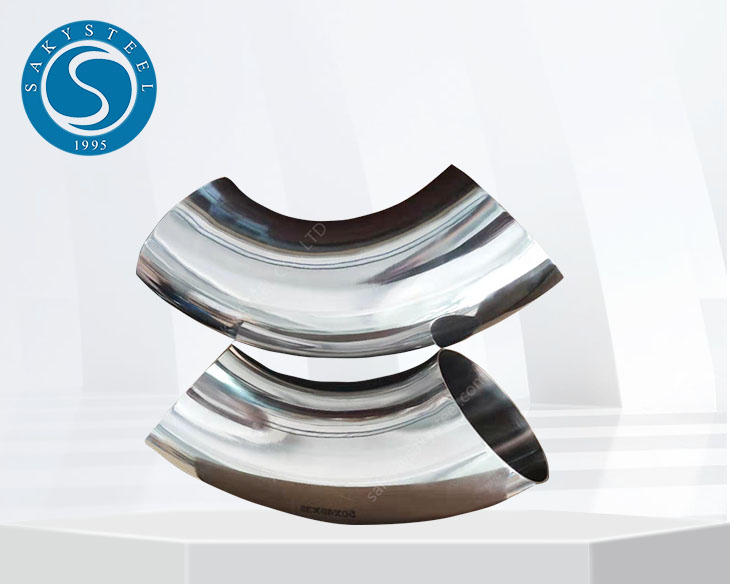

Related Products