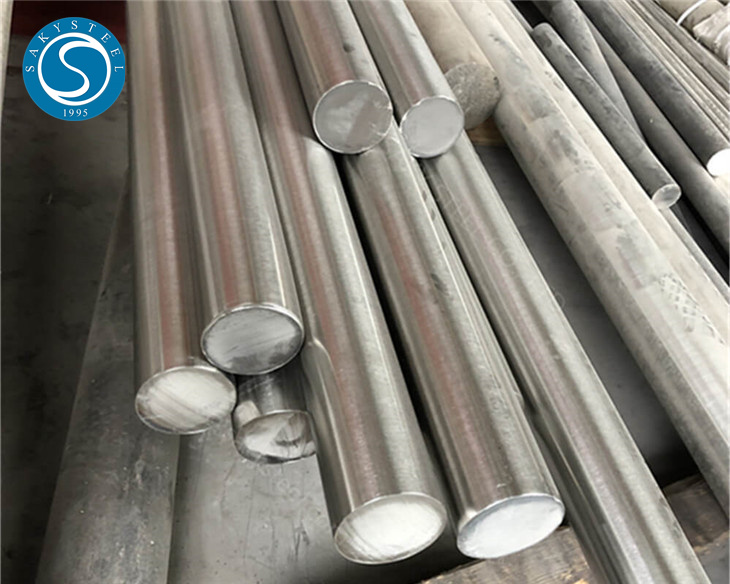

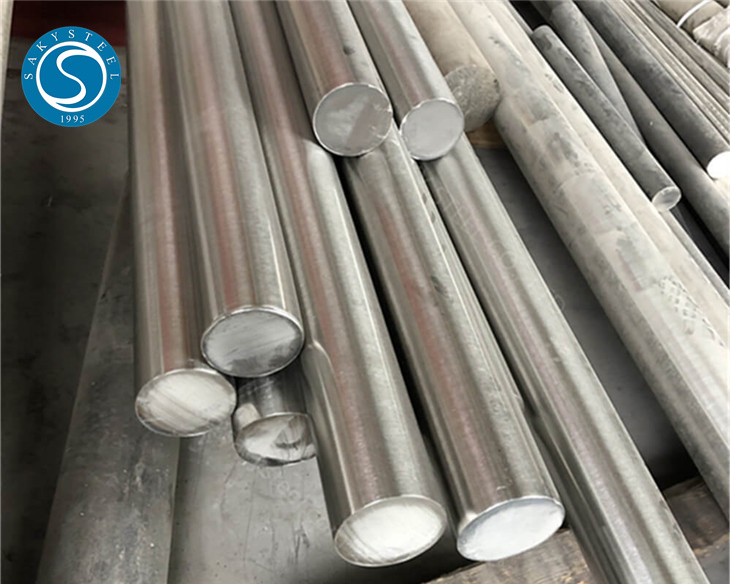

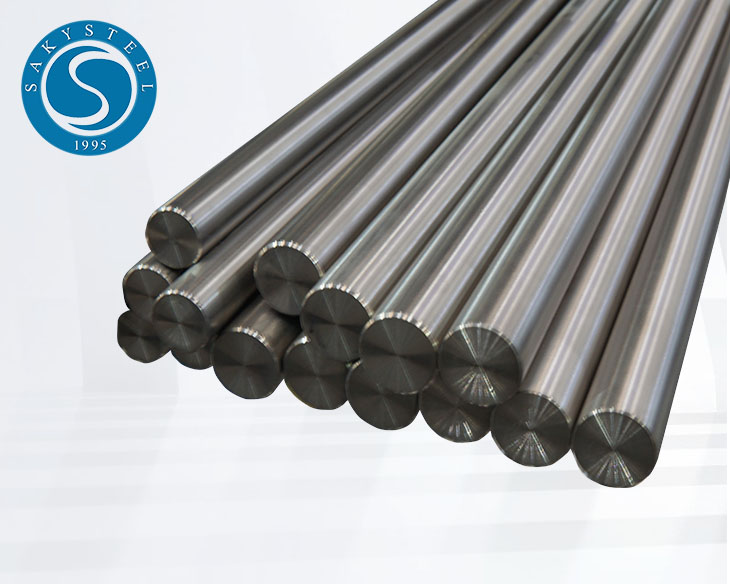

Premium 904L Stainless Steel Bar for Durability and Corrosion Resistance

When it comes to choosing the right material for your projects, I always recommend the 904L Stainless Steel Bar. This high-performance alloy is known for its exceptional resistance to pitting and corrosion, making it an ideal choice for harsh environments. Whether you’re involved in manufacturing, construction, or any industrial application, you’ll find that this stainless steel bar offers the durability and reliability you need. Many buyers appreciate how easily it can be welded and fabricated, ensuring that it fits perfectly into your designs. Plus, its aesthetic appeal can enhance the look of your final products. I personally have seen how investing in quality materials can save money in the long run by reducing maintenance costs. So, if you’re serious about quality, a 904L Stainless Steel Bar is the way to go. Don’t settle for less when the best is within your reach!

904l Stainless Steel Bar Ahead of the Curve Where Innovation Meets 2025

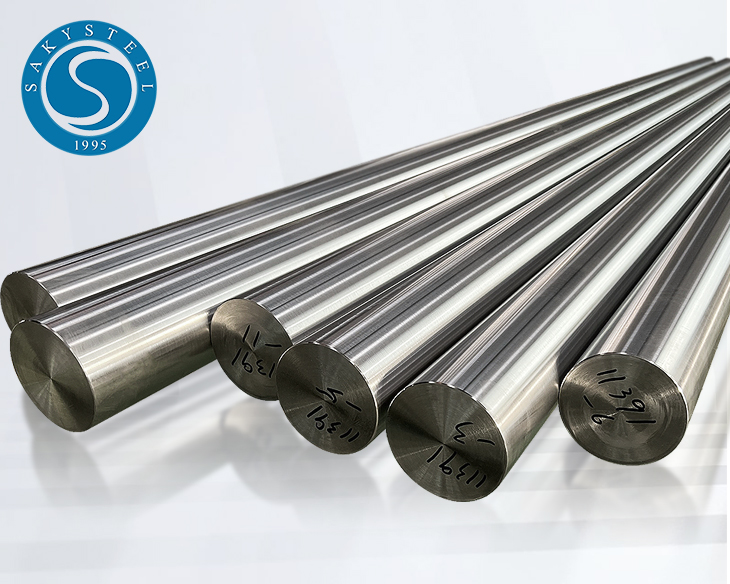

The year 2025 is set to be pivotal in the development of sustainable and innovative materials, especially in the realm of stainless steel. Among these advancements, 904L stainless steel bars are charting a new course, merging durability with cutting-edge technology. Renowned for its exceptional resistance to corrosion and high temperatures, 904L is becoming the material of choice across various industries, including chemical processing, oil and gas, and marine applications. As global demand for reliable and sustainable materials rises, the characteristics of 904L stainless steel bars position them ahead of the curve, offering unparalleled performance while minimizing environmental impact. Innovation in production methods and quality assurance processes is essential for meeting the evolving needs of manufacturers and end-users alike. With the integration of advanced technologies, such as precision machining and sustainable manufacturing practices, 904L stainless steel bars are not only cost-effective but also exhibit superior mechanical properties. Businesses investing in these innovative practices will find themselves at a competitive advantage, able to meet stricter regulations and consumer expectations for quality and sustainability. Looking ahead, suppliers and manufacturers must stay informed about trends and advancements to meet the challenges of 2025 and beyond. The transition towards more sustainable industrial practices highlights the necessity for materials like 904L stainless steel that combine performance with environmental responsibility. As more industries embrace green initiatives, the importance of high-quality 904L stainless steel bars cannot be overstated, establishing them as an essential component for future-oriented projects across the globe.

904L Stainless Steel Bar Ahead of the Curve Where Innovation Meets 2025

| Property | Value |

|---|---|

| Corrosion Resistance | Excellent |

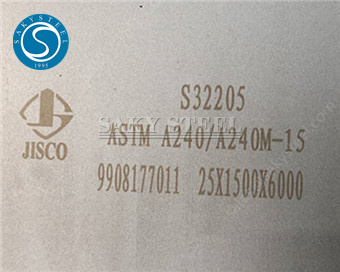

| Chemical Composition | Ni: 24%, Cr: 20%, Mo: 4% |

| Applications | Oil & Gas, Chemical Processing |

| Standard Length | 3 m, 6 m |

| Diameter Range | 10 mm - 300 mm |

| Tensile Strength | ≥ 520 MPa |

| Yield Strength | ≥ 200 MPa |

| Elongation | ≥ 35% |

Related Products